Aerospace

Aerospace

Industry Pain Points

-

Accuracy is difficult to guarantee

Backward traditional equipment

Production process limitation

Cutting accuracy is difficult to guarantee

-

Complicated production process

High labor cost

Poor material utilization

Production efficiency is difficult to guarantee

-

Serious processing pollution

The process is smoky

Cutting fluids pollute the environment

Loud vibration

Specific Applications

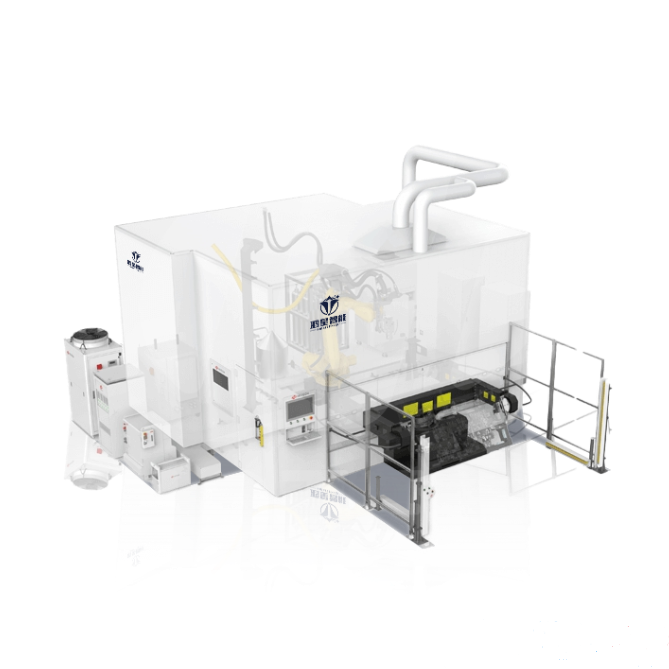

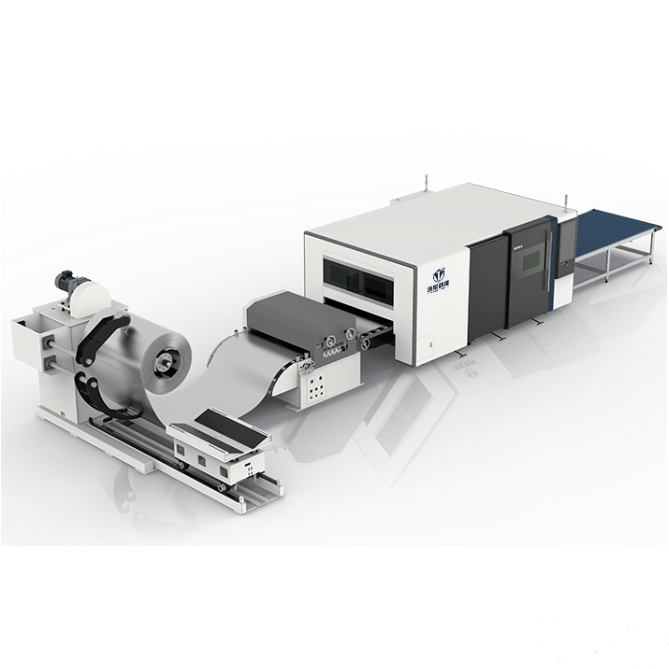

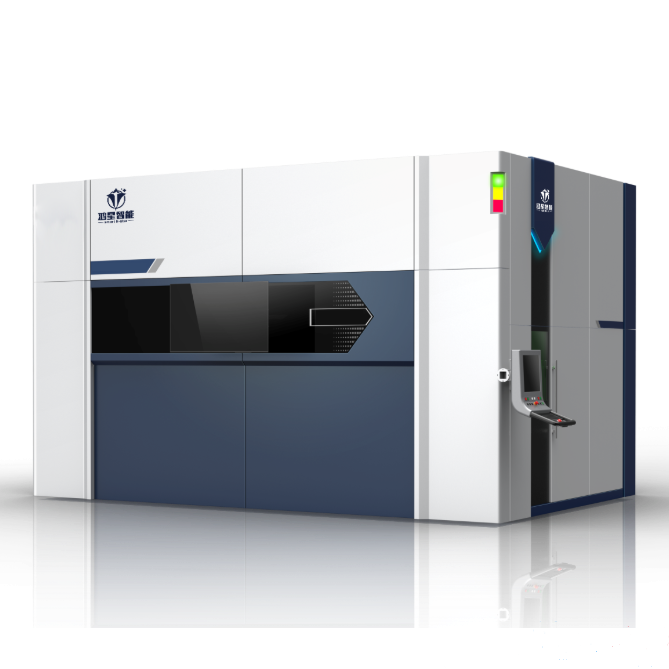

The aerospace industry has extremely high requirements for processing types and specifications, processing accuracy, quality, etc., the laser cutting machine has a series of advantages such as good beam quality, high precision, small slit, material saving, smooth cutting surface and safe operation, and the finished product is smooth after processing, no burrs, no secondary processing, and the quality and efficiency are greatly improved.

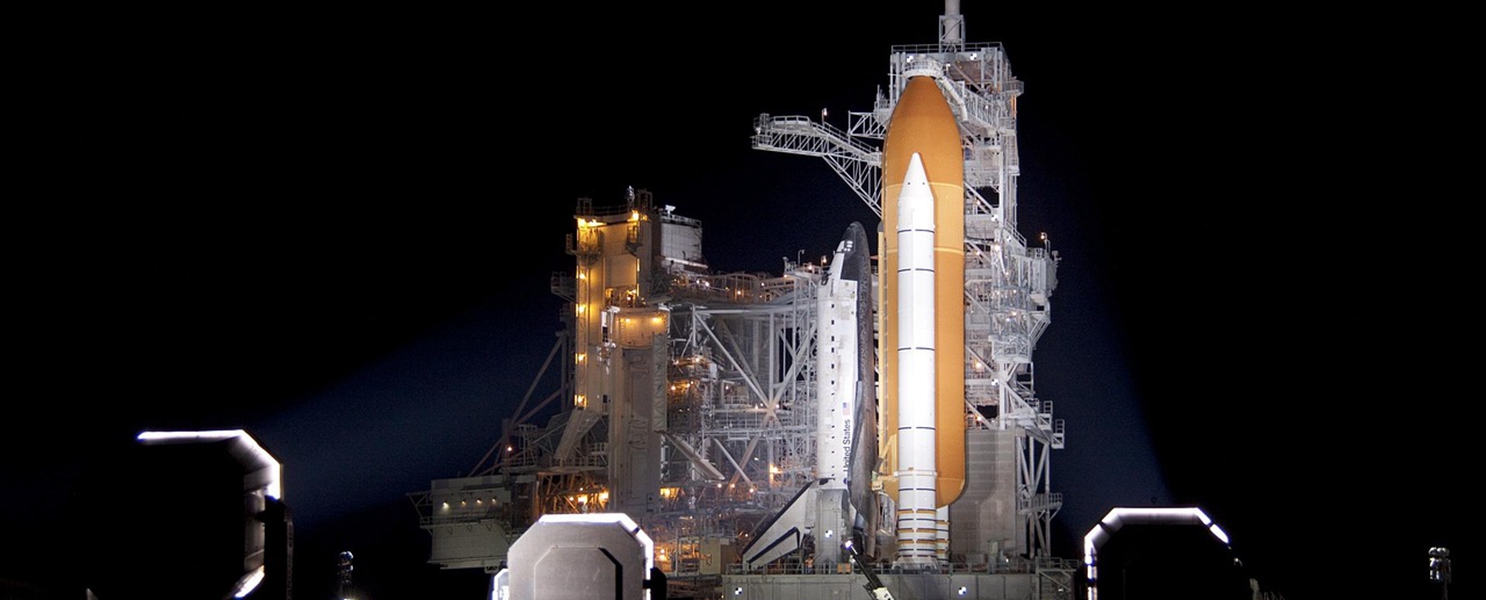

Aircraft manufacturing

Aerospace materials processing

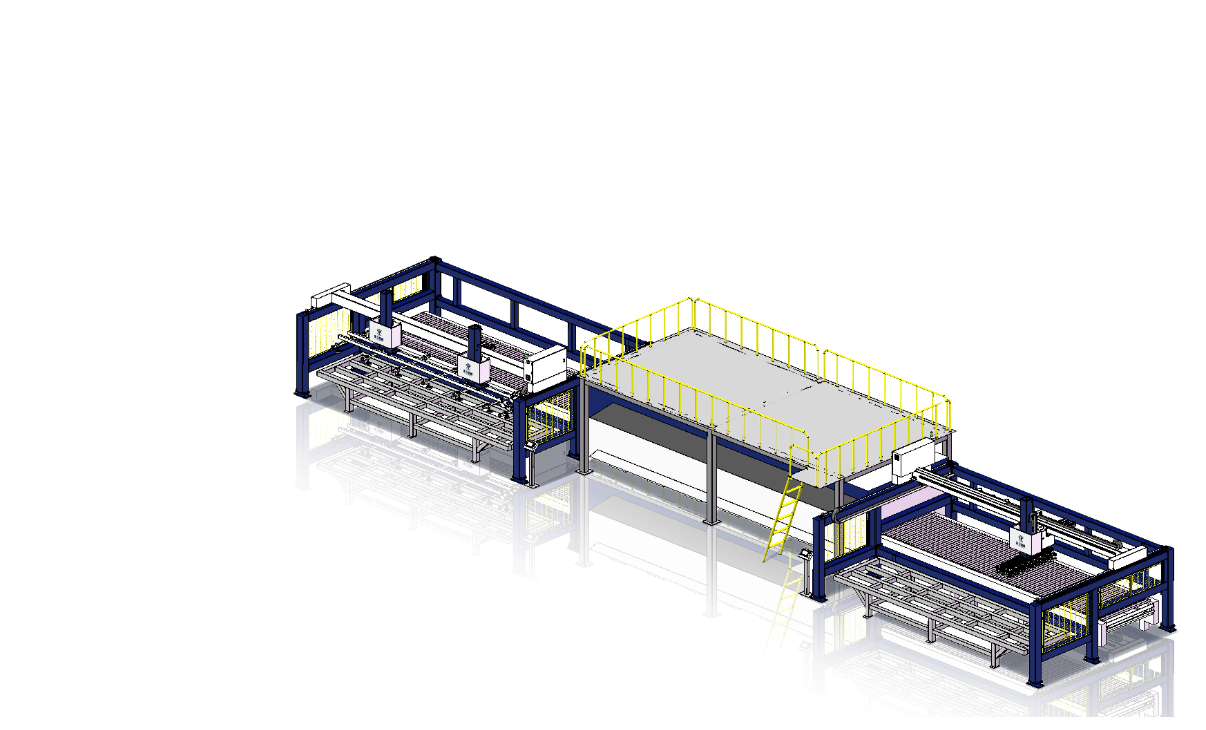

Aerospace maintenance and modification

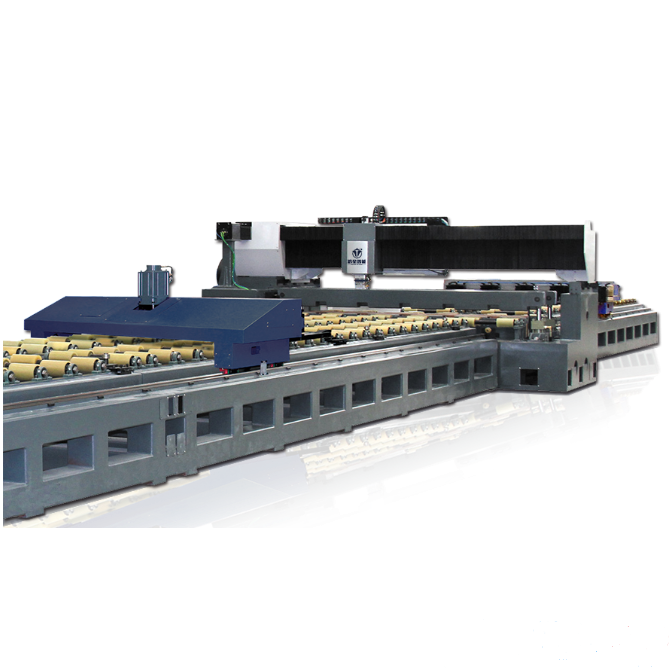

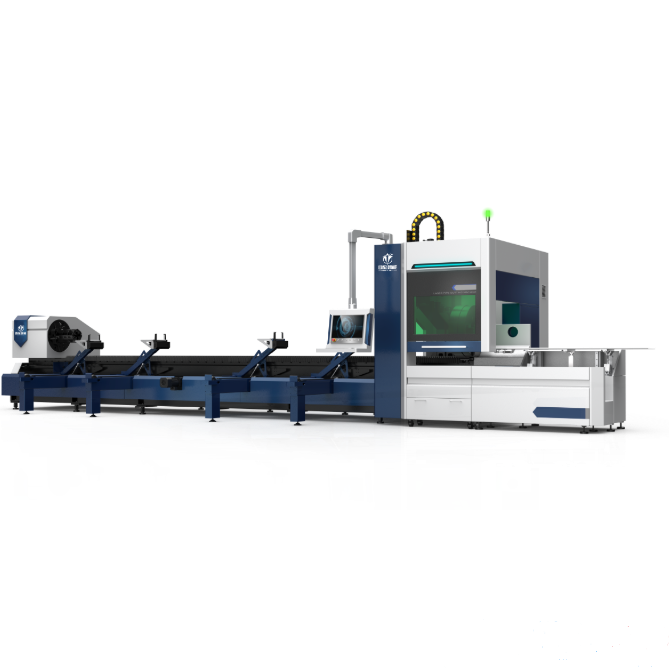

It mainly includes the manufacturing of aircraft fuselage and wing shell, structural parts, engine blades, turbine disks, missile shells, satellites, rockets, spacecraft and other spacecraft manufacturing.

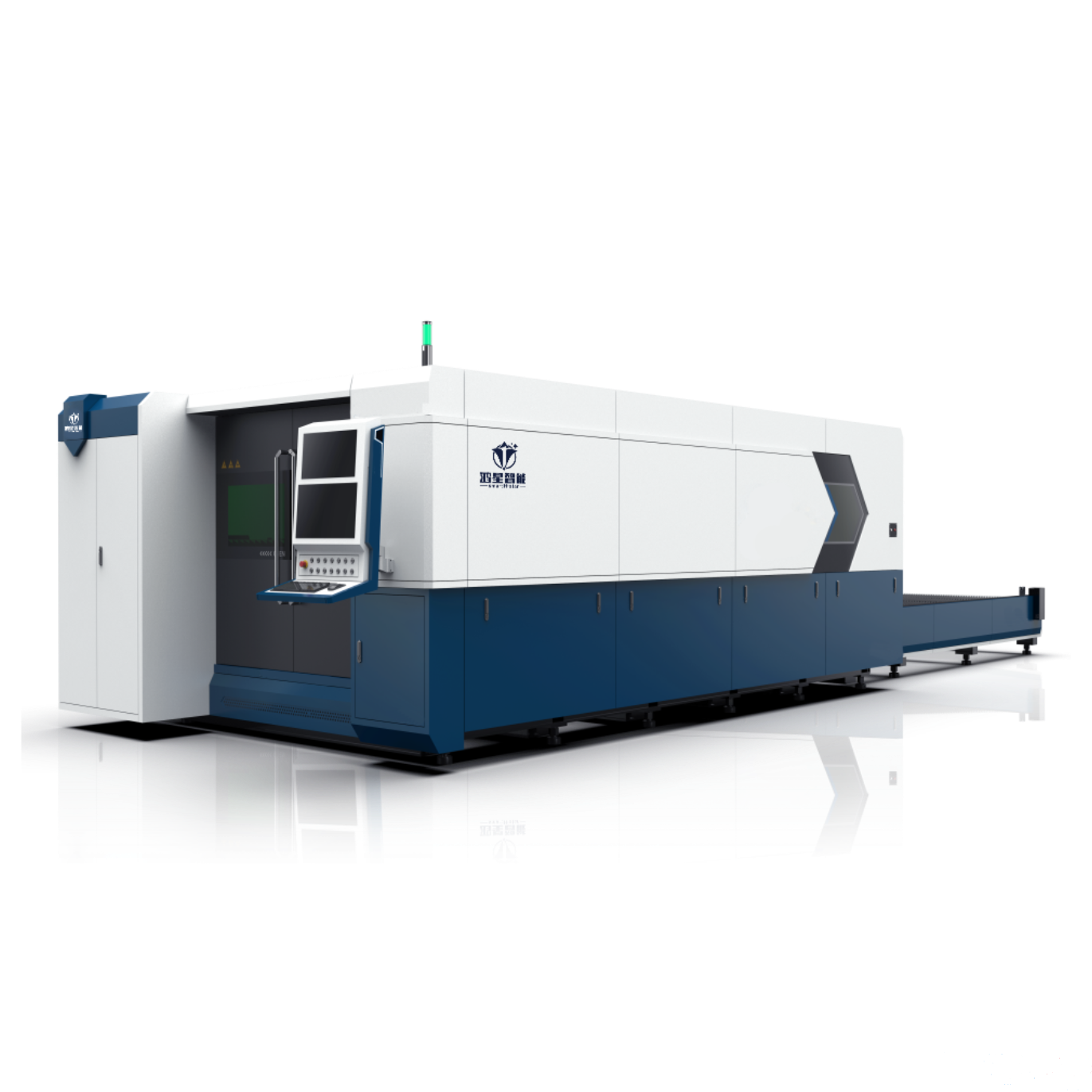

Various aerospace materials of aluminum alloy, titanium alloy, stainless steel and other parts processing, especially for mold, bearings, gears and other complex shape, high precision parts processing.

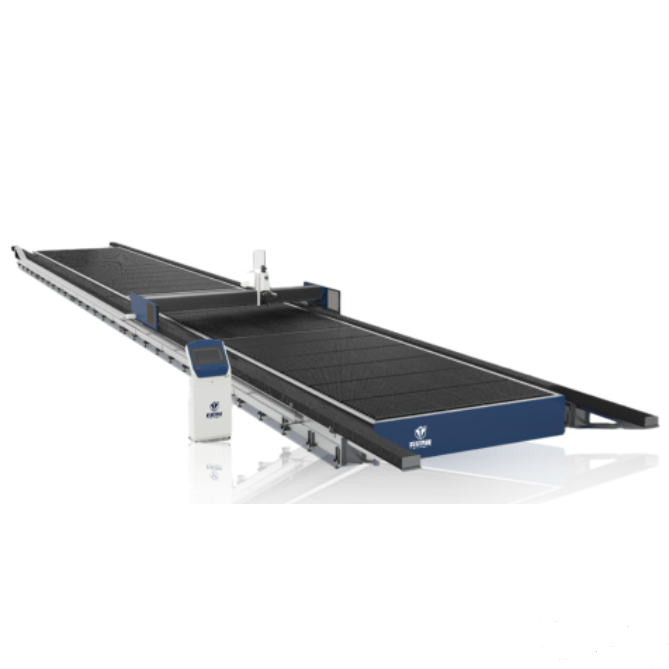

Including satellites, rockets, spacecraft, aircraft, helicopters and other aircraft maintenance and modification.