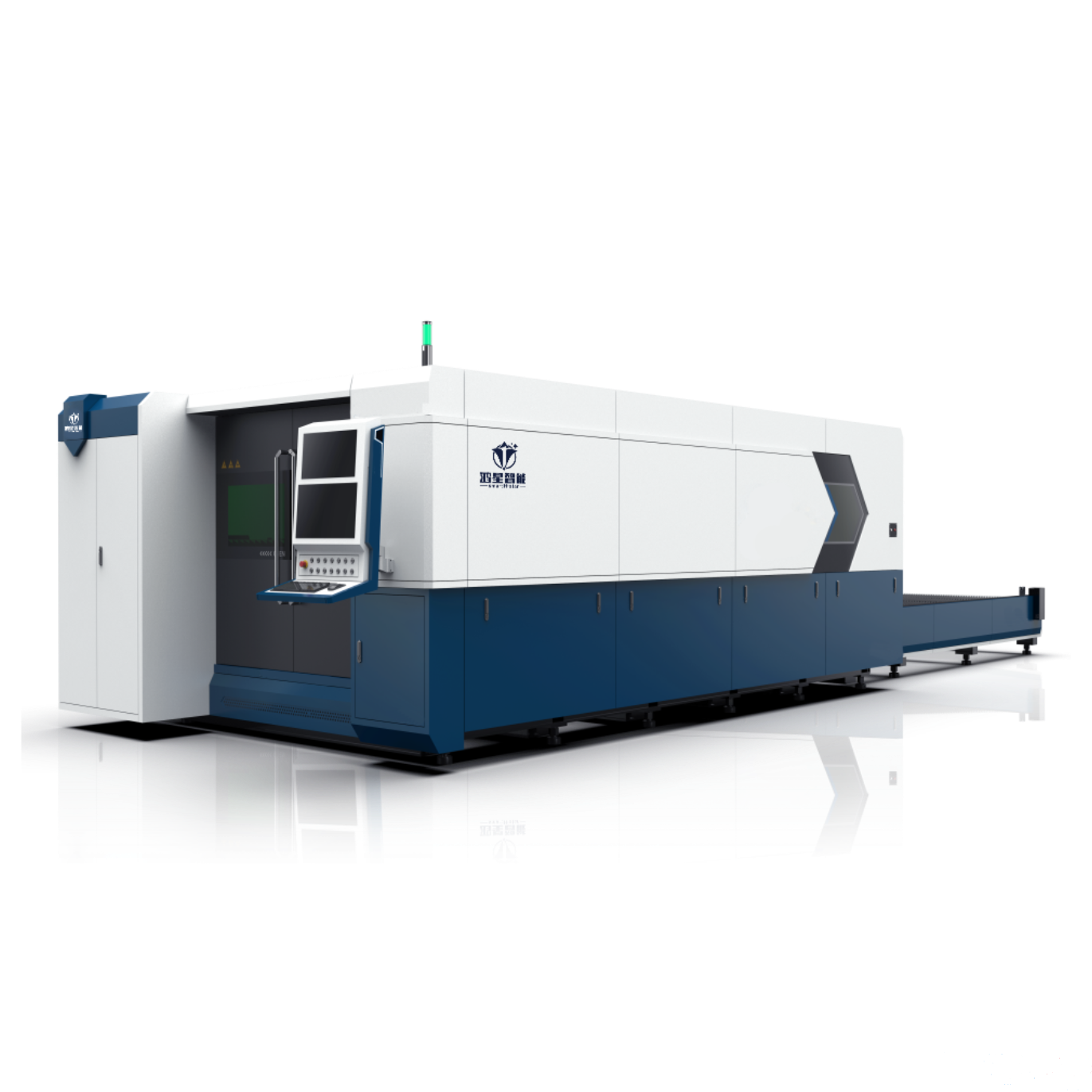

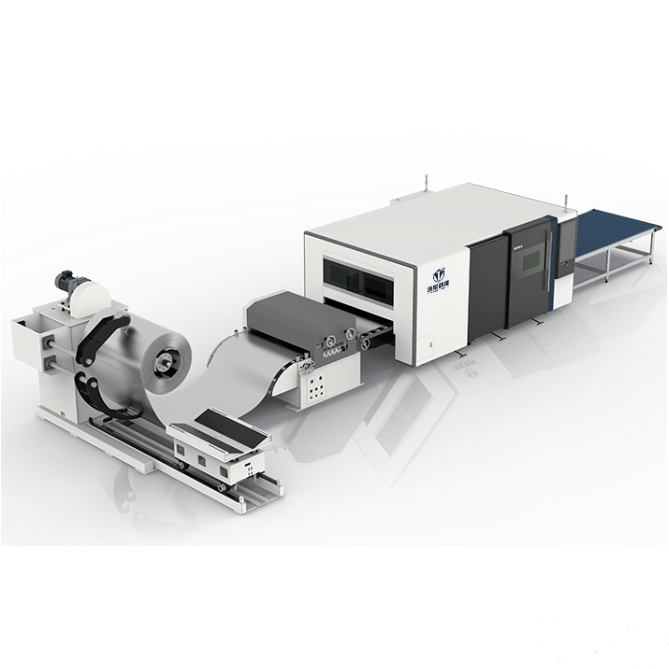

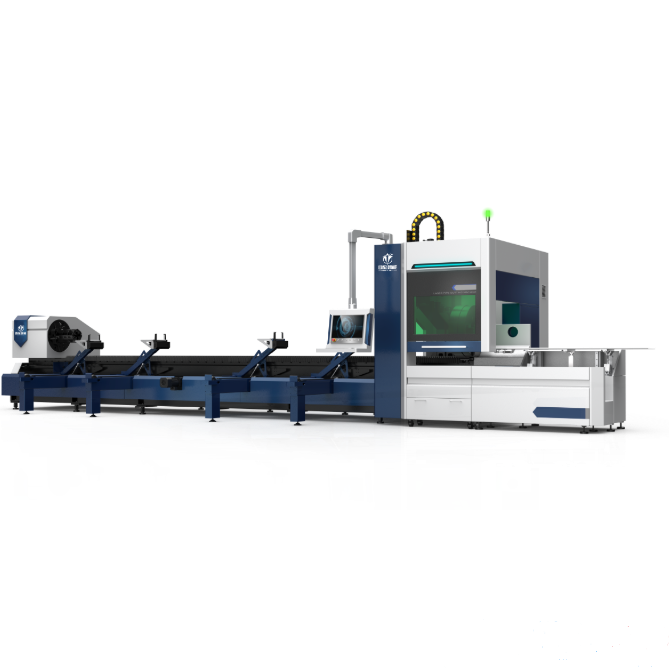

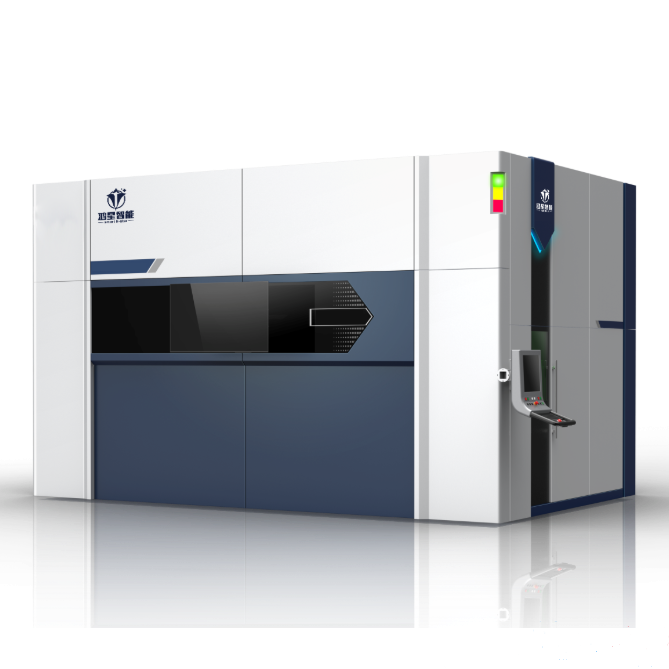

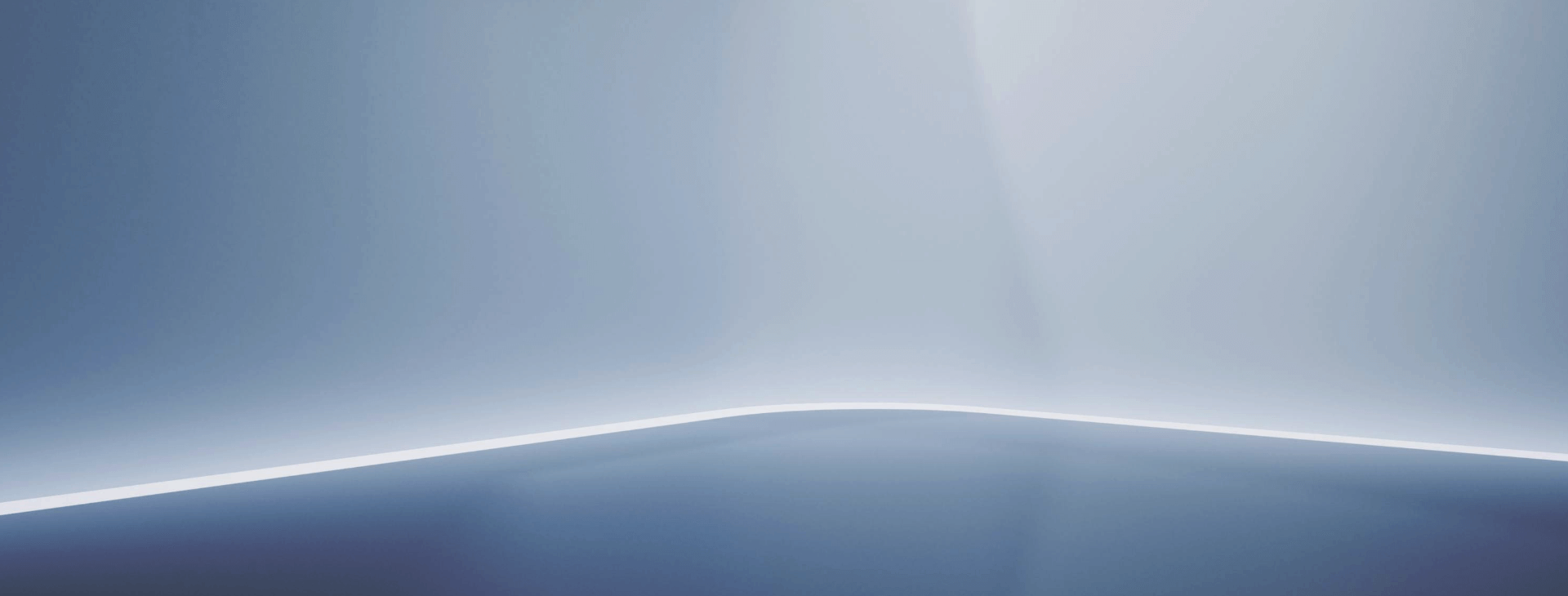

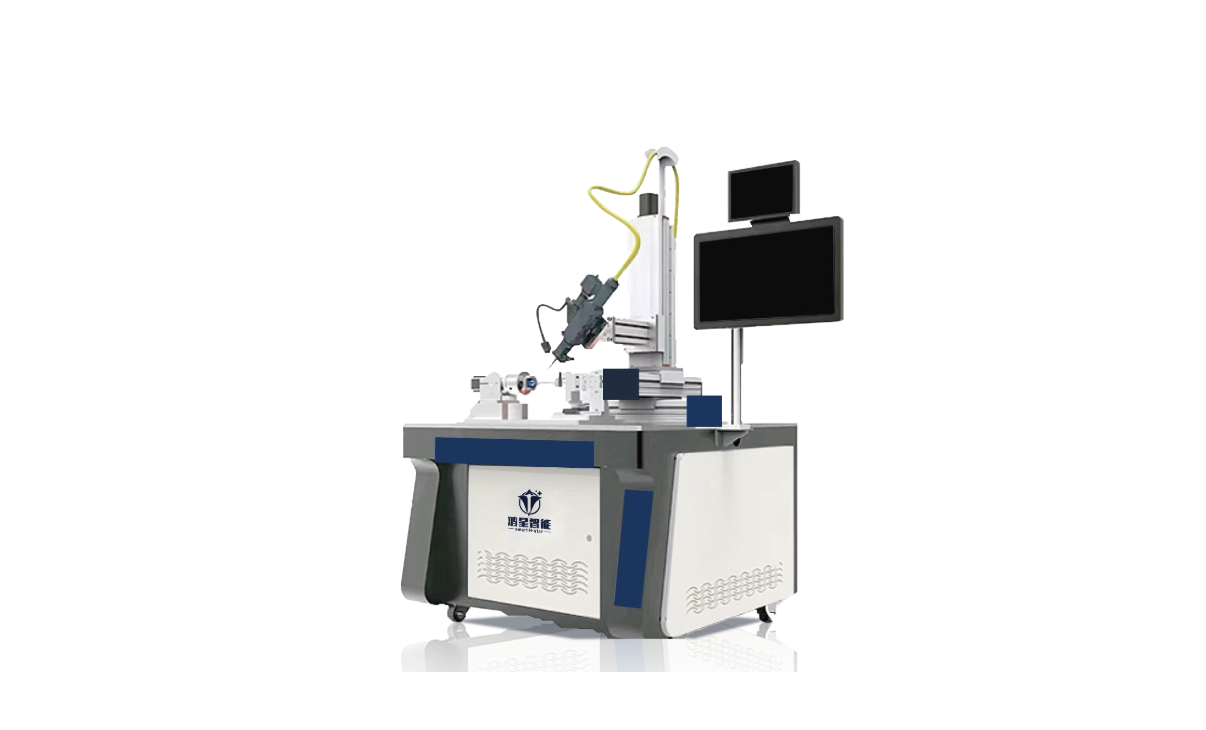

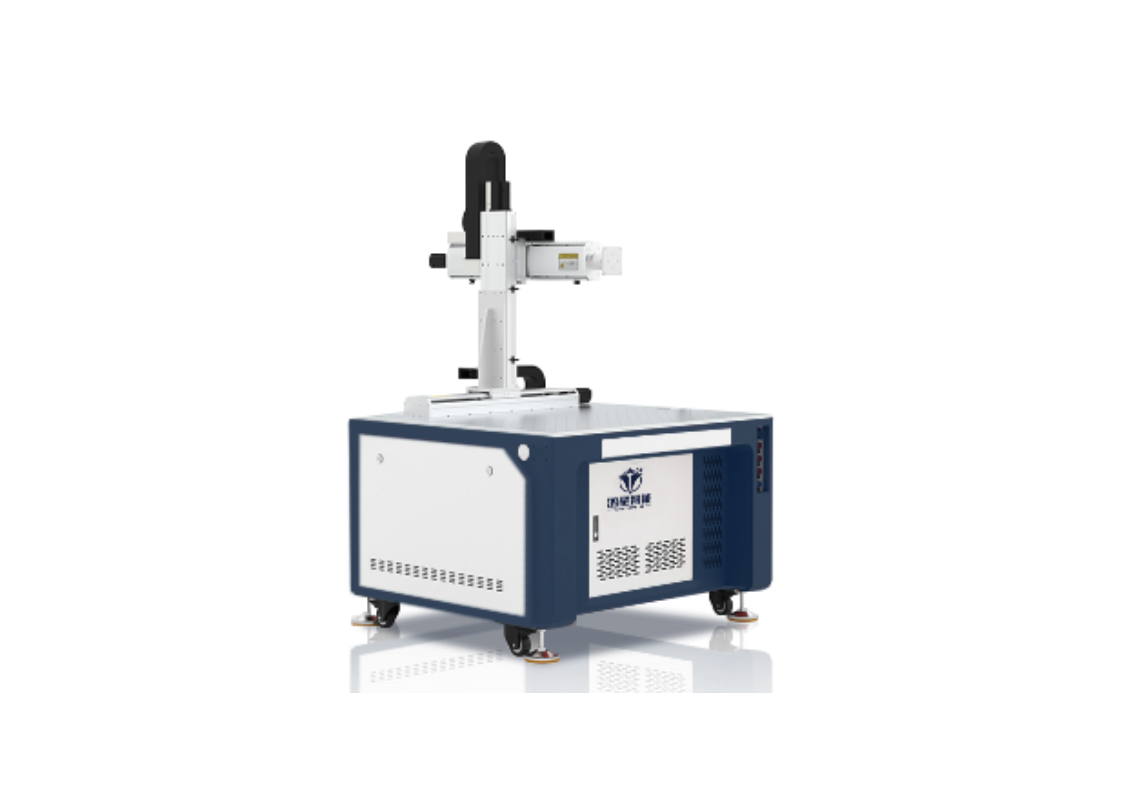

HSLW-γ

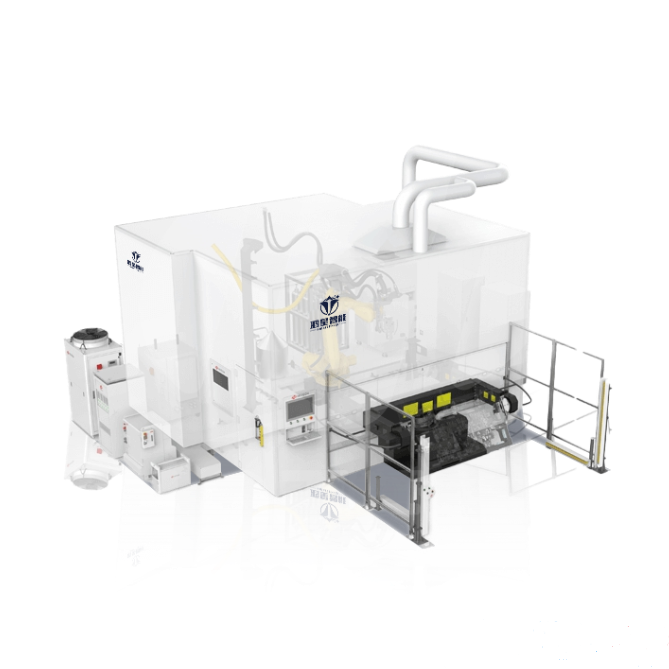

Platform laser welding machine

Application Area

- ·Aerospace

- ·Machine building

- ·Electronics industry

- ·Communication facility

- ·Chemical equipment

- ·Automobile manufacturing

Swing joint

New style light weight, small size, compact structure, simple operation;

Optimized internal sealing design, highly dust-proof;

Stable and convenient drive and control integration, strong anti-interference ability, simple external wiring;

Various swing graphics 8 kinds of welding graphics, suitable for different process requirements;

Strong compatibility with the display control, offline, PC control and other working modes.

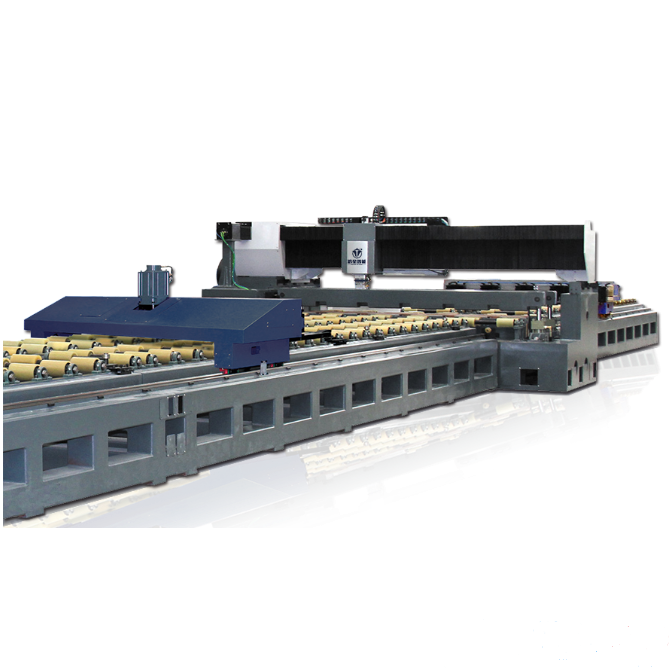

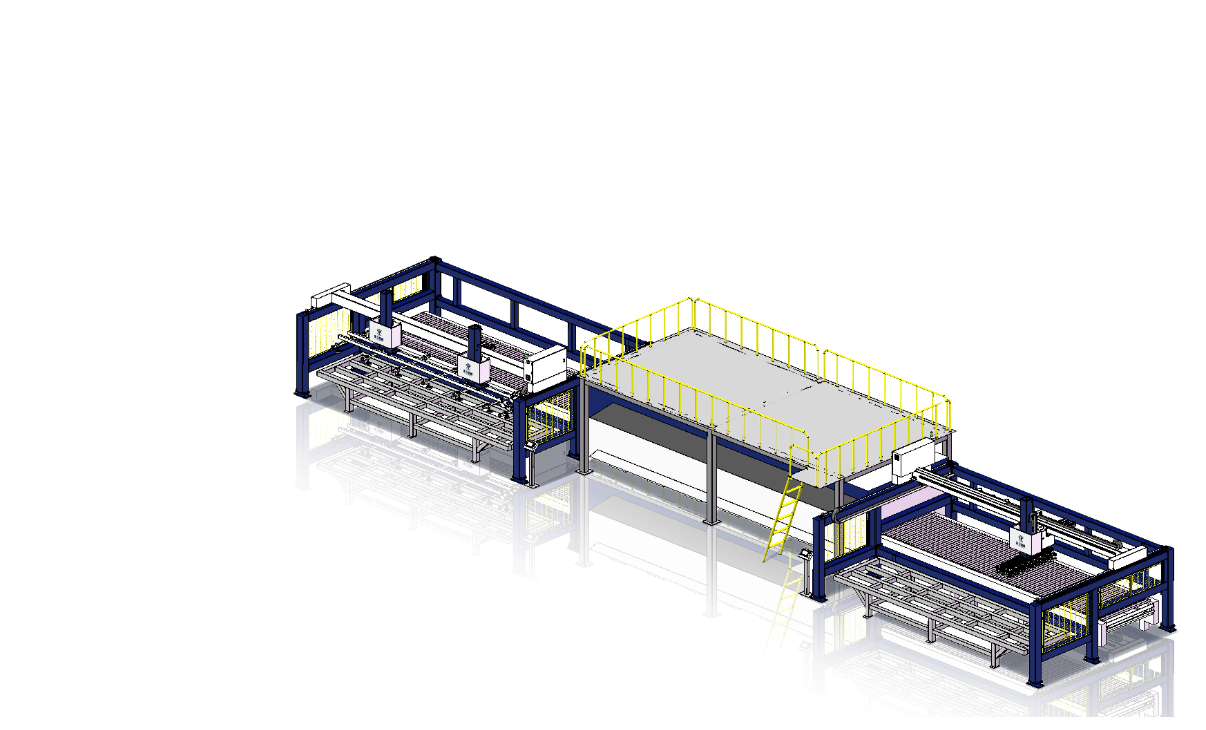

Laser welding platform

Independently developed three-axis laser automatic welding platform, efficient and flexible three-axis cantilever structure;

High repeated positioning accuracy, smooth and stable, high walking straightness;

Stable welding track, shock-proof design, compact structure;

peculiarity

Table integrated laser, built-in water tank, reasonable space;

Touch screen + hand joystick operation mode, teaching programming, easy to use, programming fast;

Double Y table of gantry type can realize double station operation, with higher working efficiency;

The XYZ workbench can be used as an independent production unit or connected production.

Can carry different working tools;

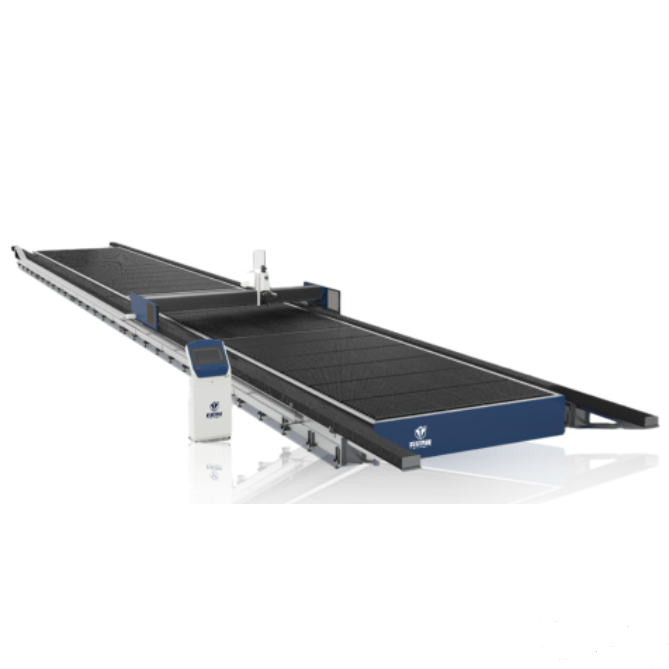

Mainly applicable to stainless steel, carbon steel, alloy steel, silicon steel, spring steel, aluminum, aluminum alloy, galvanized plate, aluminum plated zinc plate and other metal welding;

Technical Parameter

| Equipment type | HSLW-γ1500 | HSLW-γ2000 | HSLW-γ3000 |

| Rated output power (W) | 1500 | 2000 | 3000 |

| Working mode | continuous | continuous | continuous |

| Power adjustment range (%) | 30~100 | 30~100 | 30~100 |

| Central wavelength (nm) | 1068±10 | 1068±10 | 1068±10 |

| Maximum power consumption (KW) | 6 | 7.5 | 9 |

| Electricity running cost (8h) | 48kwh | 60kwh | 72kwh |

| Welding thickness of carbon steel plate (mm) | 0.5~4 | 0.5~5 | 0.5~6.5 |

| Stainless steel plate welding thickness (mm) | 0.5~4.5 | 0.5~5.5 | 0.5~6.5 |

| Aluminum alloy plate welding thickness (mm) | 0.5~4 | 0.5~5 | 0.5~5.5 |

| XYZ axis travel | 500*300*300(mm)optional |

| Performance characteristics | The standard three-axis linkage can realize the welding of any trajectory in the plane space |

| Standard axle | 3 axes (optional 4 ~ 6 axes) |

| Maximum bearing capacity | 250kg |

| Travel speed | ≤6000mm/min |

| Blowing mode | Coaxial/paraxial |

| Aiming and fixing | Red light +CCD camera monitoring system |

| Electricity demand | 220V±5%/380V±5% 50HZ |

| Table size | 800*1000*1800(mm) |

*The appearance, parameters, performance description, and comparative data of the products displayed on this page are for reference only, and the actual product shall prevail.

Application Industry

-

Aerospace

-

Machine building

-

Electronics industry

-

Communication facility

-

Chemical equipment

-

Automobile manufacturing

Product Video