Shipping

Shipping

Industry Pain Points

-

Serious pollution

Production and processing smoke

Cutting fluids pollute the environment

Hidden danger of production safety

-

Low production efficiency

Complex manufacturing process

Secondary grinding

High labor cost

-

Poor machining accuracy

Production process limitation

The quality varies

Poor precision waste

Specific Applications

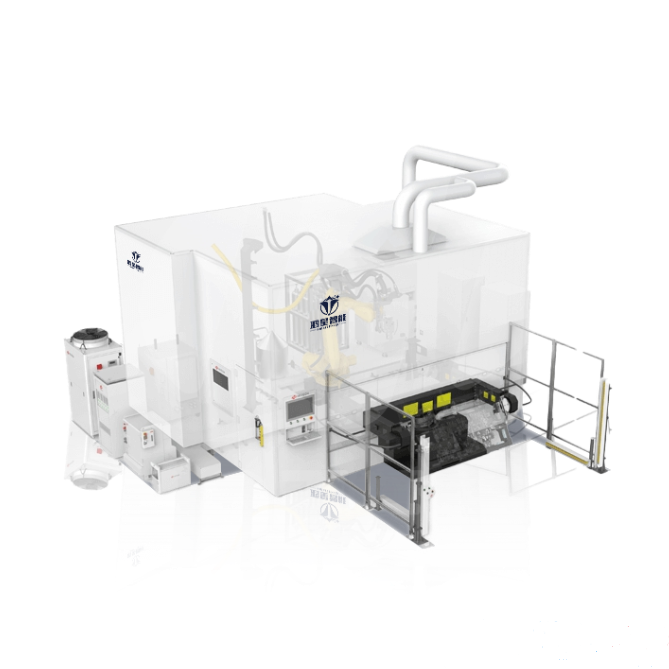

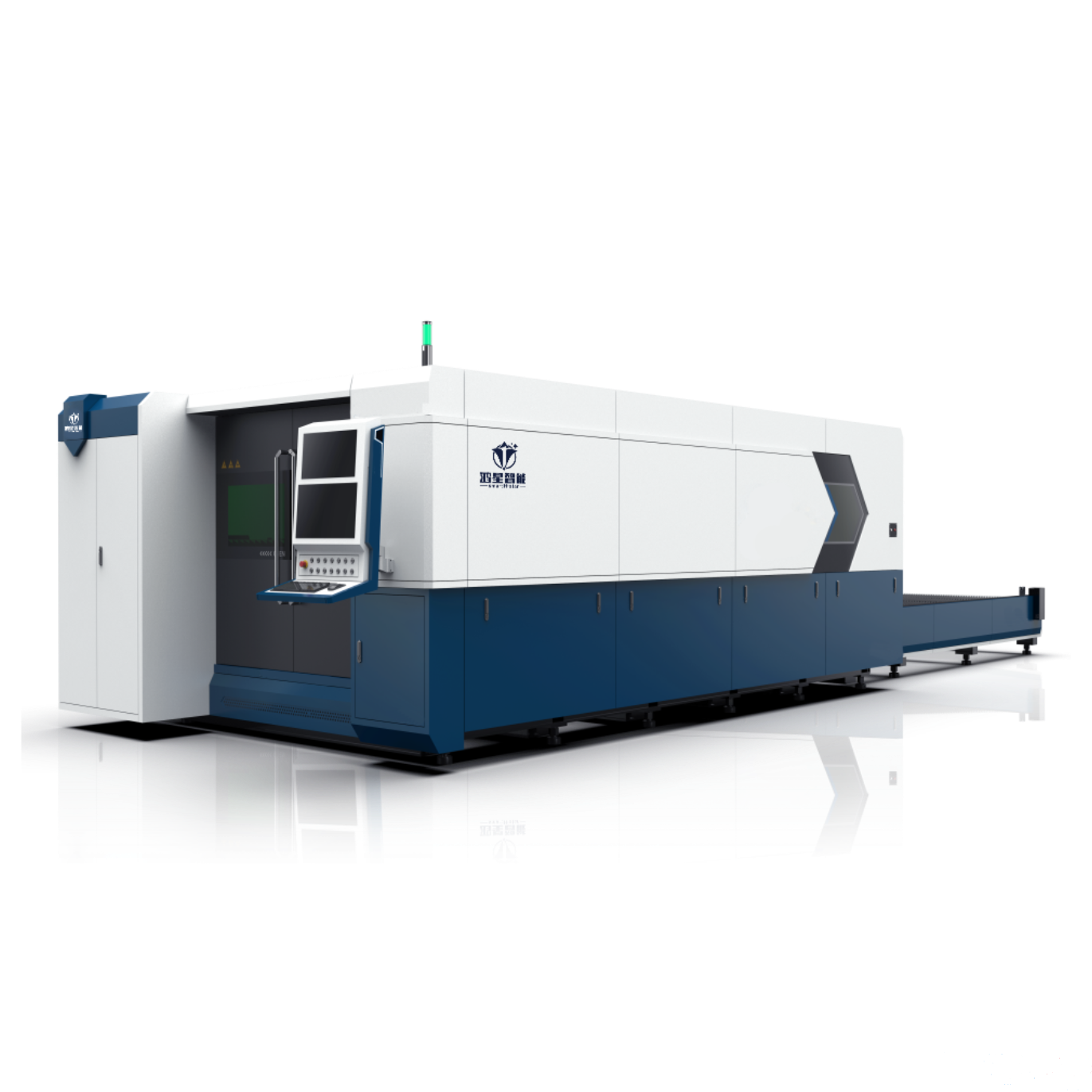

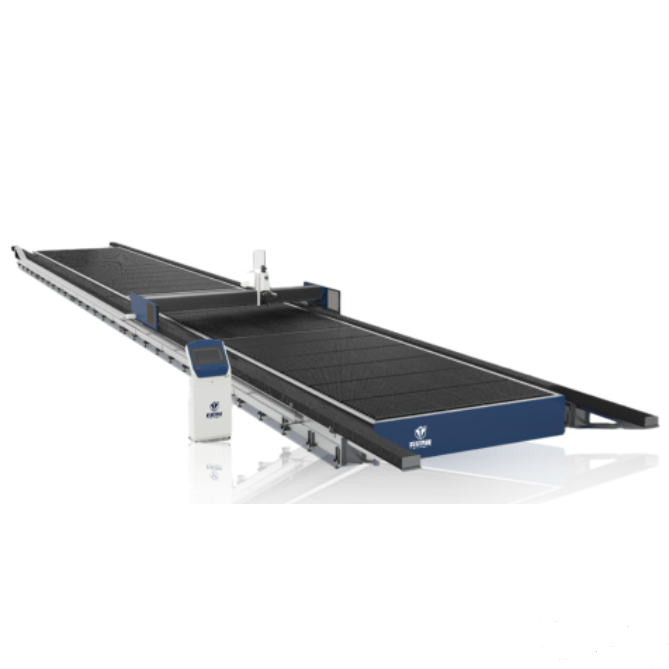

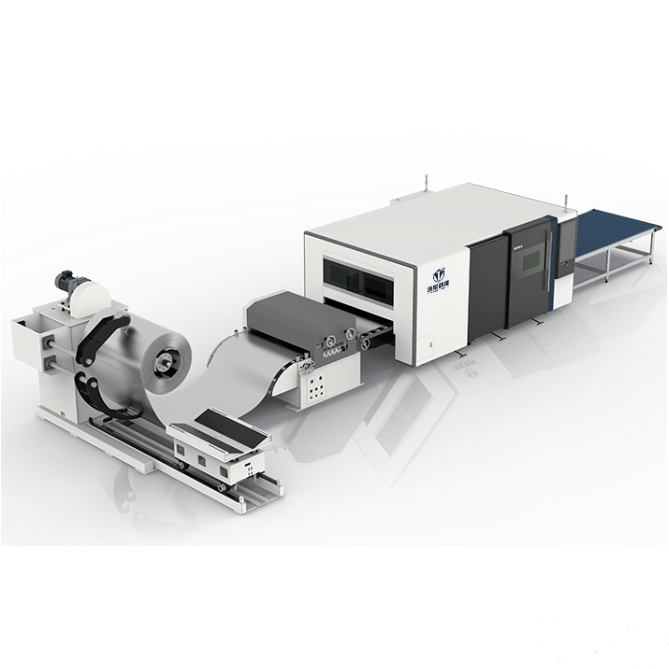

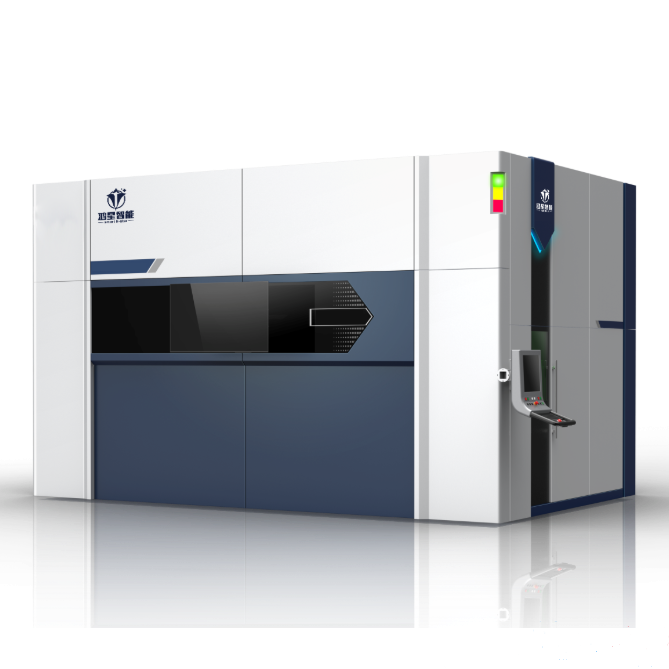

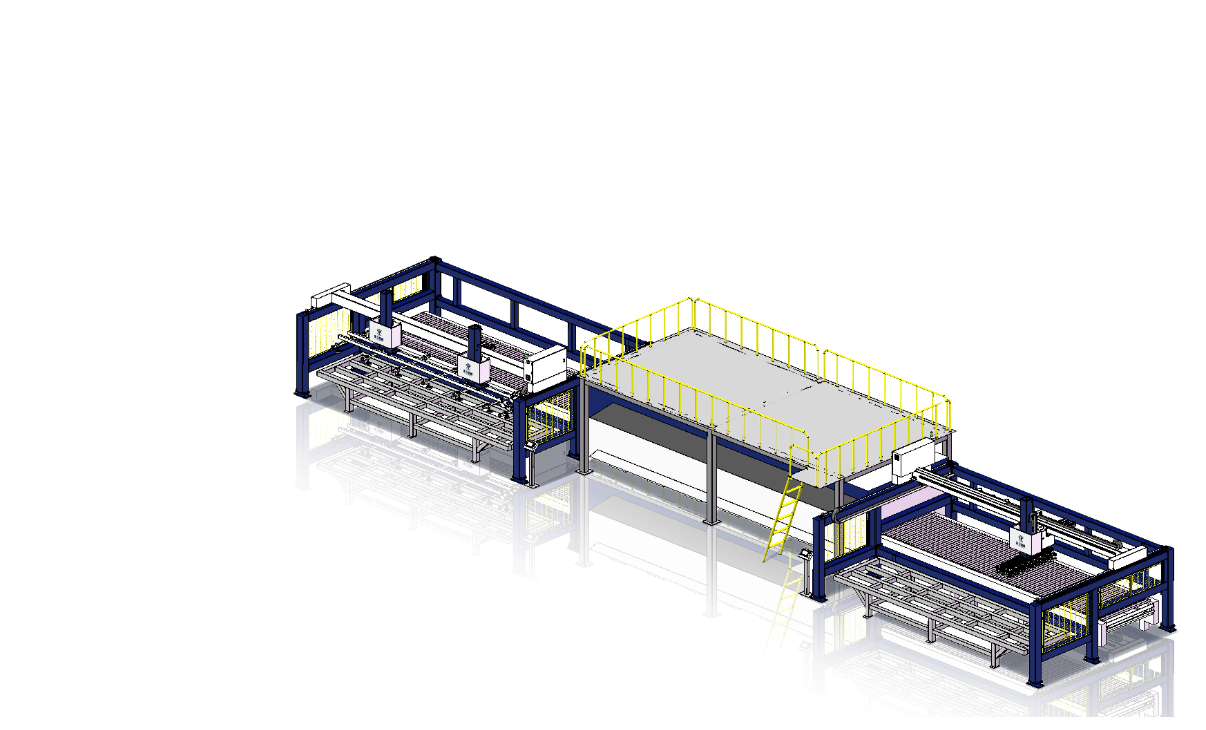

The main process involved in the manufacture of shipbuilding industry is cutting and welding, and it is a big user of metal welding and cutting. In recent years, many large shipyards have widely used large format thick plate laser cutting machine. Ourui laser efficient, green, intelligent, accurate cutting technology, greatly improve the production efficiency and product quality.

System piping

Power line

Ship keel

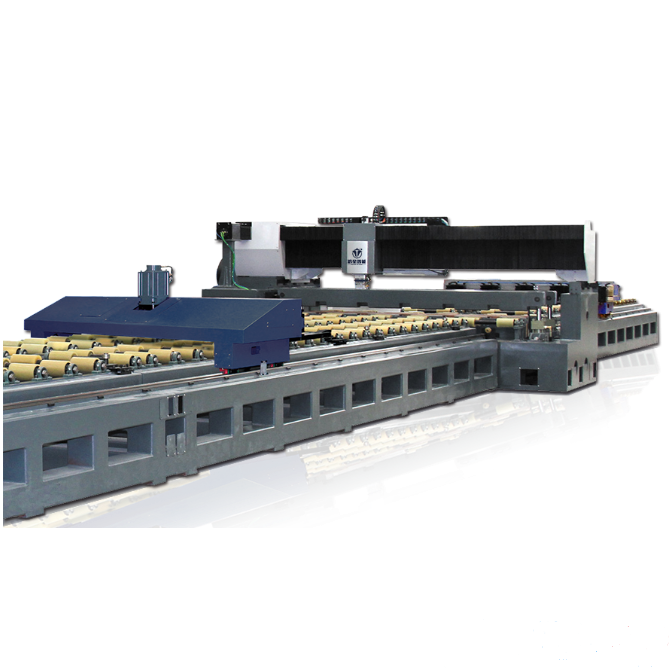

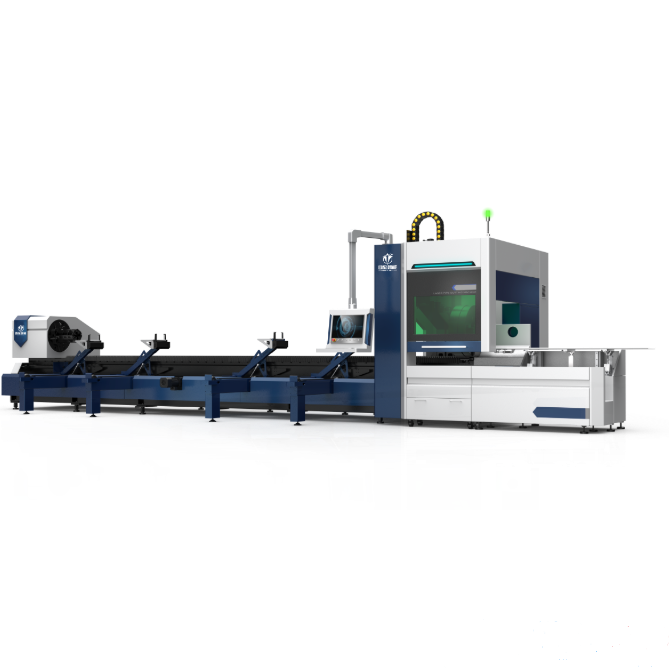

The function of this kind of pipe system is to ensure the ship's unsinkable, fire safety, navigation performance and to meet the life needs of crew and passengers. Mainly for the bilge pipe, ballast pipe, fire pipe, air pipe, injection pipe, measuring pipe, water supply pipe, drainage pipe and cabin ventilation pipe cutting processing.

The role of this type of pipe is to ensure the normal work of the mechanical equipment and is an important part of the entire power plant. Mainly for fuel pipe, slide pipe, sea water pipe, fresh water pipe, compressed air pipe, exhaust pipe and other cutting processing.

The main function of ship keel is load-bearing, which is the most important load-bearing structure of ships, especially small ships, to withstand the longitudinal bending moment of the hull and ensure the structural strength of the ship. Mainly for the ball flat steel cutting processing.