Steel

Steel

Industry Pain Points

-

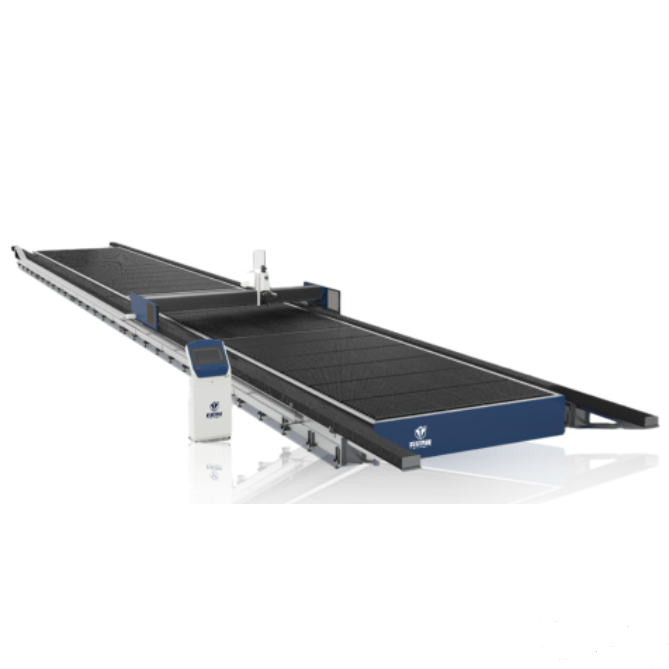

Inflexible processing

Traditional equipment has a single function

Short service life

There is no guarantee of personal safety

-

Low production efficiency

Complex manufacturing process

Secondary grinding

High labor cost

-

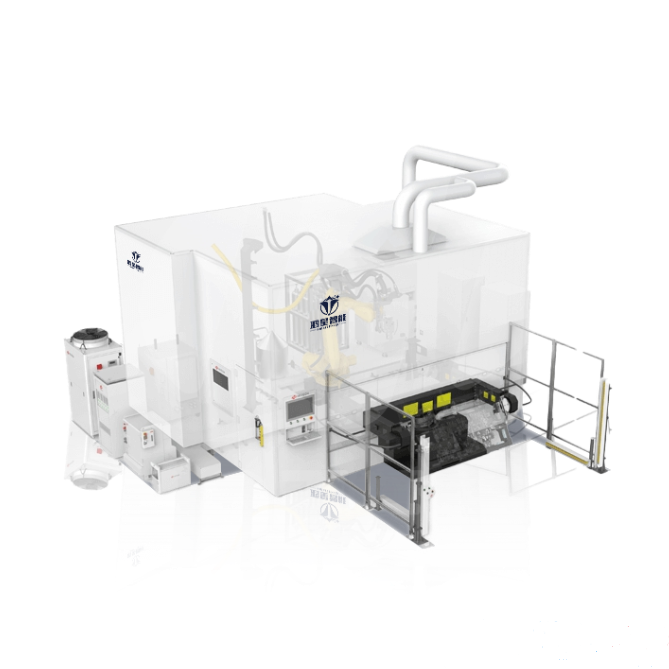

Serious processing pollution

The process is smoky

Cutting fluids pollute the environment

Serious noise pollution

Specific Applications

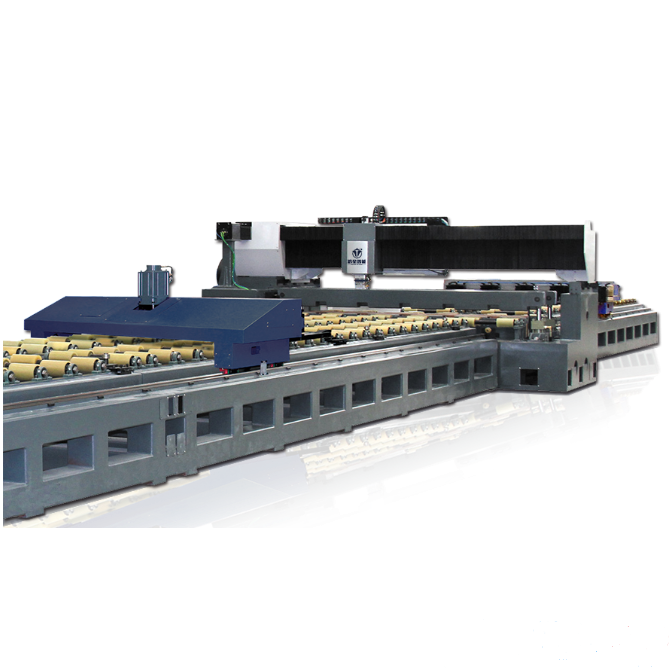

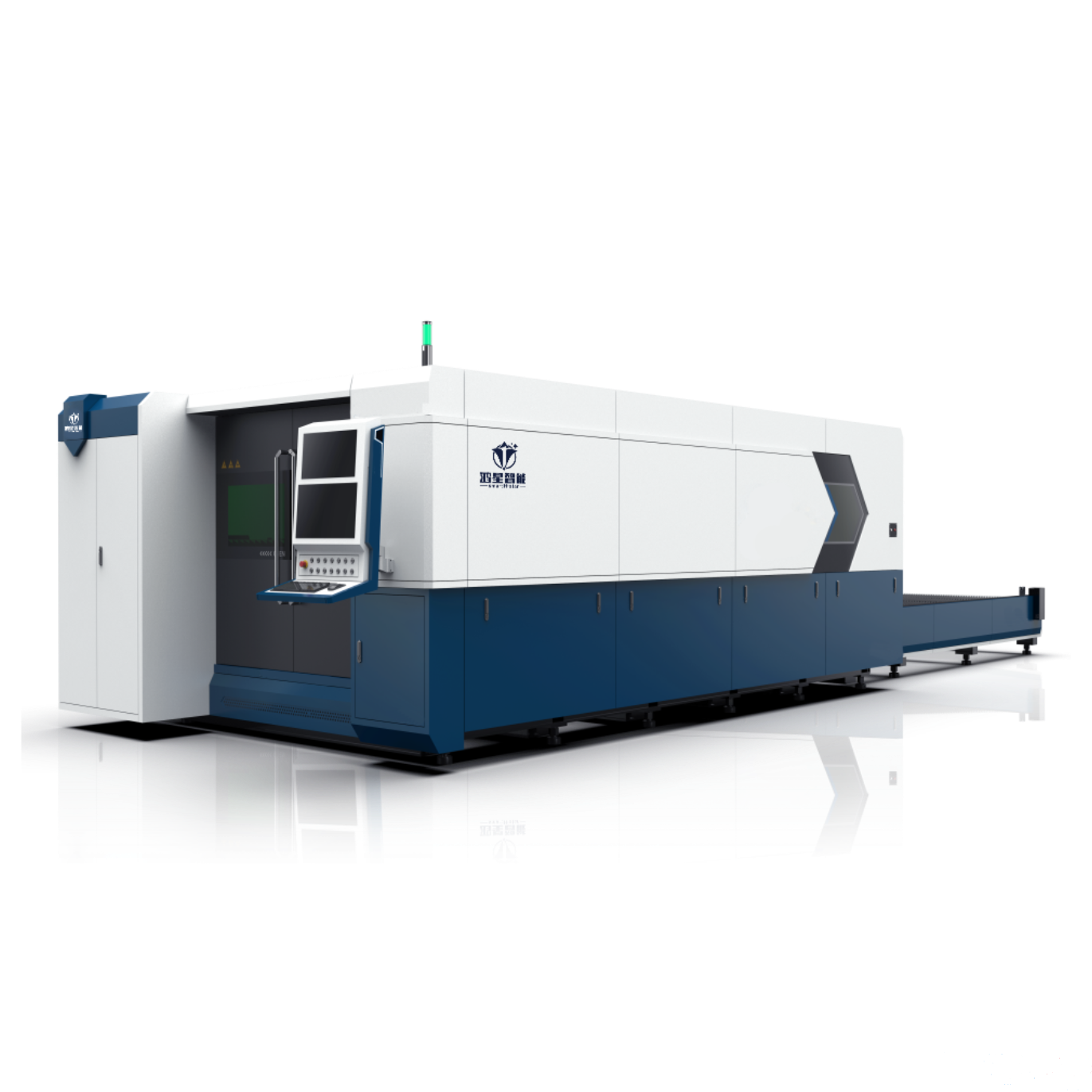

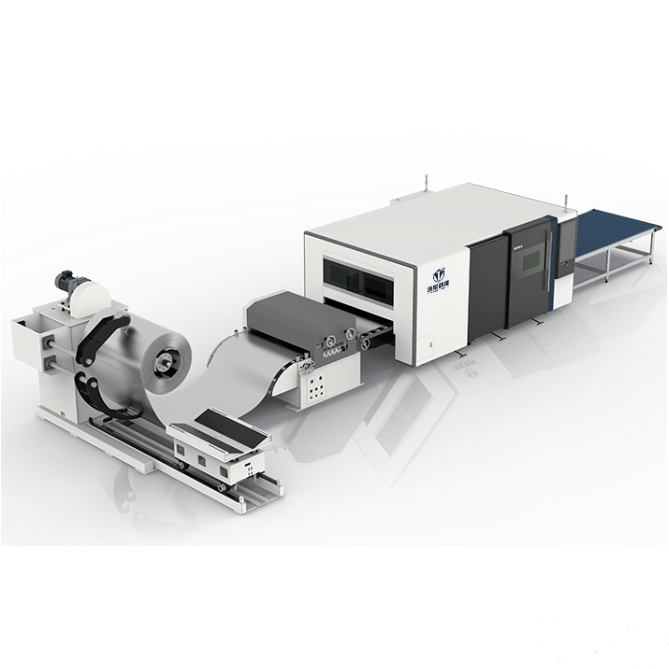

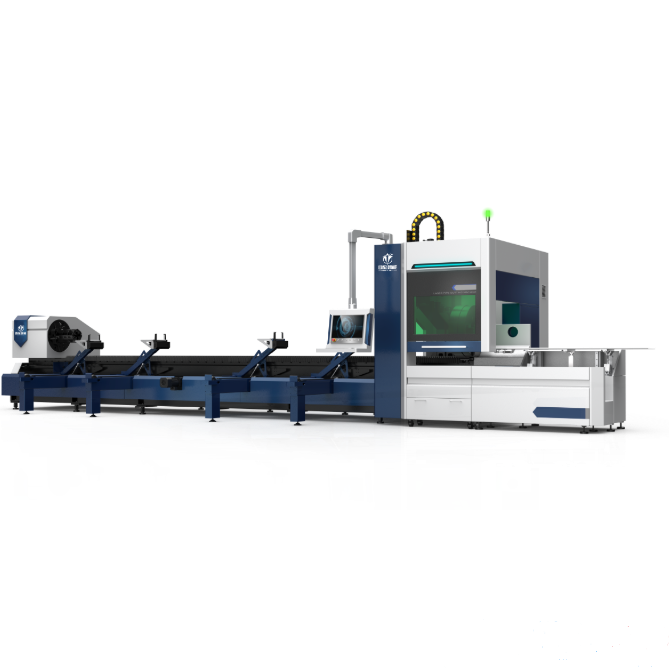

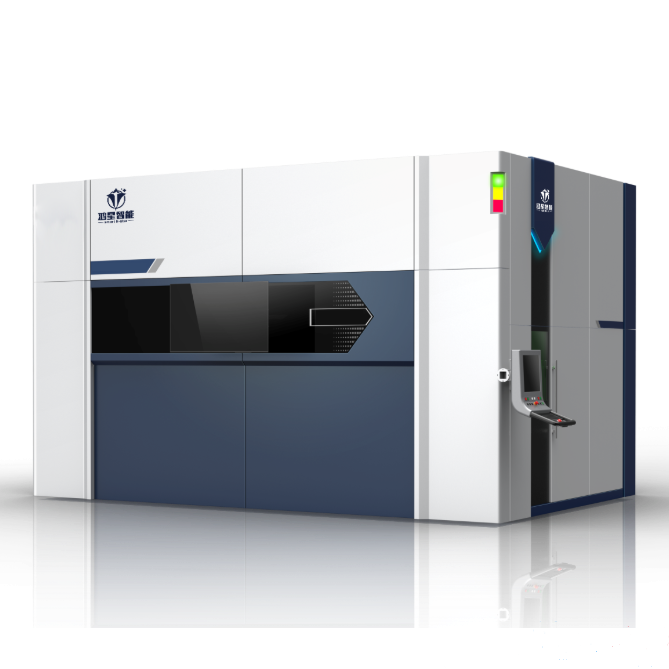

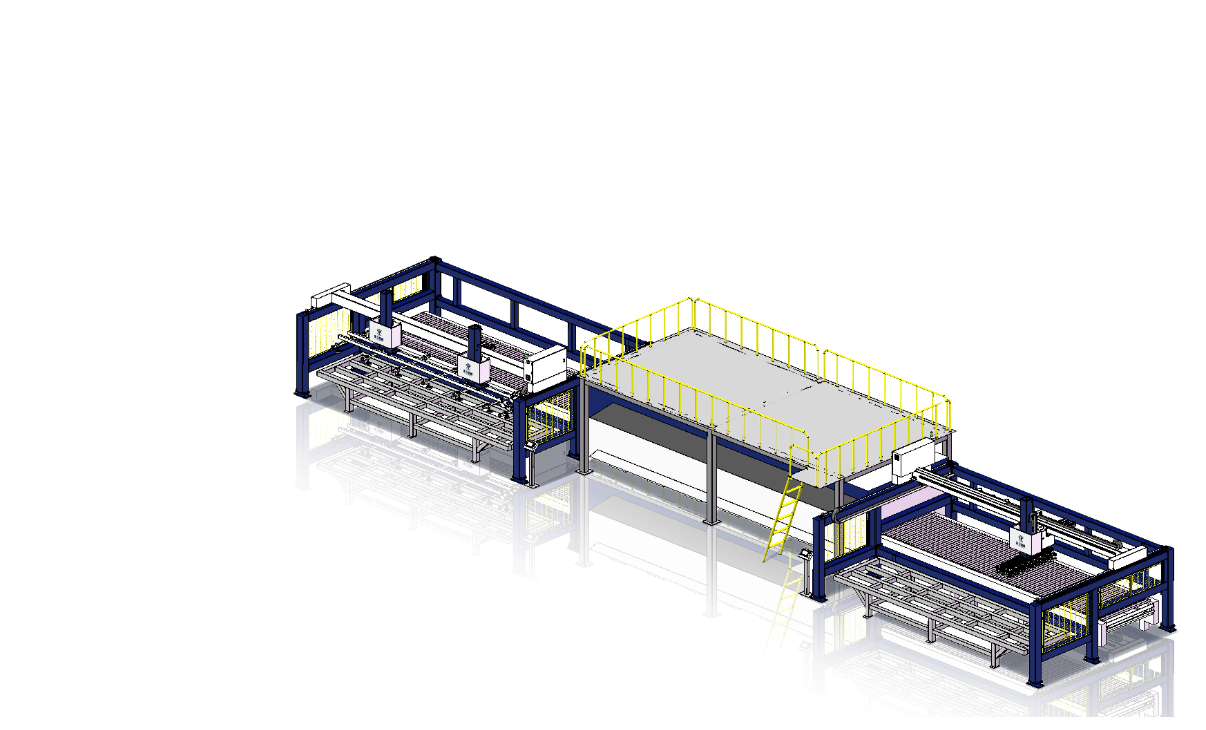

In the field of steel structure engineering processing, about 73% of the processing operations need to be completed with laser cutting technology. Compared with traditional cutting, Ourui laser cutting technology has the advantages of high precision, strong adaptability, low noise, good cutting quality, etc., and the finished product after processing is smooth, no burr, no secondary processing, and the quality and efficiency are greatly improved.

Large span steel structure

High-rise structure

Heavy steel structure

Processing of steel structural parts required for hangar, airport, garage, train station, conference hall, gymnasium, exhibition hall, movie theater, etc.

For TV tower, microwave tower, communication tower, transmission line tower, petrochemical tower, air monitoring tower, rocket tower, tourist observation tower, drilling tower, exhaust tower, water tower, chimney, etc., required steel structural parts processing.

Open hearth workshop, priming workshop and smelting workshop of metallurgical plant; Steel casting workshop and forging workshop of heavy machinery factory; Shipyard berth workshop; Assembly shop of aircraft manufacturing plant; As well as some other workshops of roof truss, column, crane beam and other load-bearing systems, required steel structural parts for processing.