Hongxing Intelligent-Collaborative Robot Welding Station: Reshaping the Future o

Release Date:2025/03/28

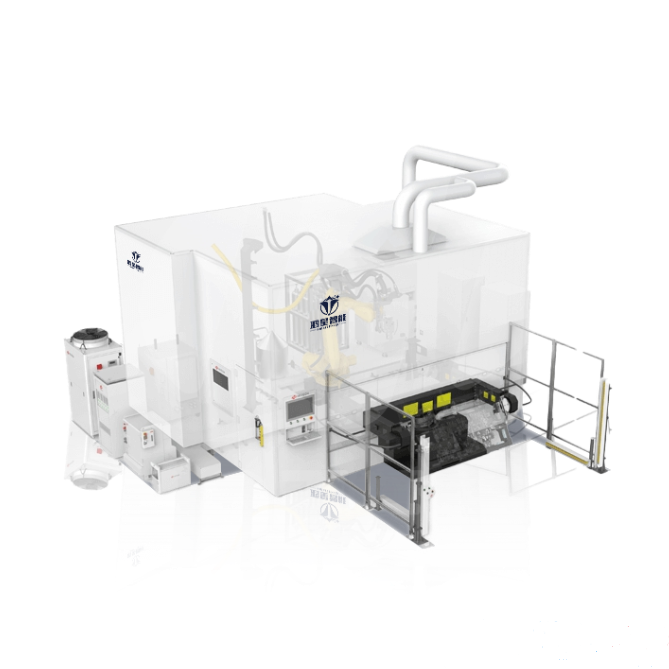

In the manufacturing industry's continuous pursuit of high efficiency, precision and safety today, welding as a key process link, its technological innovation is crucial. Hongxing Intelligent for industrial production to bring a subversion of the traditional welding tool - collaborative robot welding station, it will bring unprecedented changes in industrial production experience.

Traditional Welding Pain Points: The Dual Challenge of Efficiency and Safety

Traditional welding operations are often faced with many difficulties. On the one hand, manual welding efficiency is low, and welding quality by the welder skill level, working condition and other factors, it is difficult to ensure consistency; on the other hand, the welding environment is harsh, high temperature, strong radiation, harmful gases, etc. on the welder's health poses a serious threat to the safety of accidents occur from time to time. In addition, with the rising labor costs, the pressure on production costs of enterprises is also increasing. Furthermore, industrial robot welding has complex programming, technical expertise requirements and other issues have been plagued by the majority of practitioners.

More efficient automated welding solutions

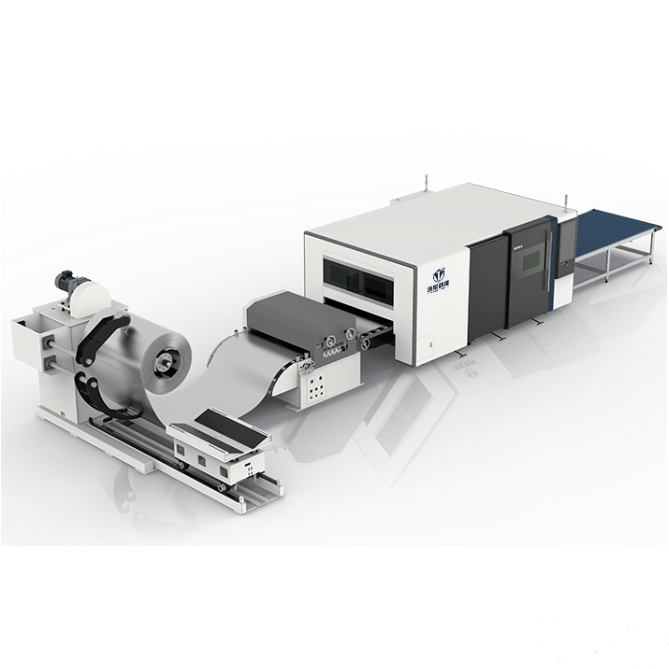

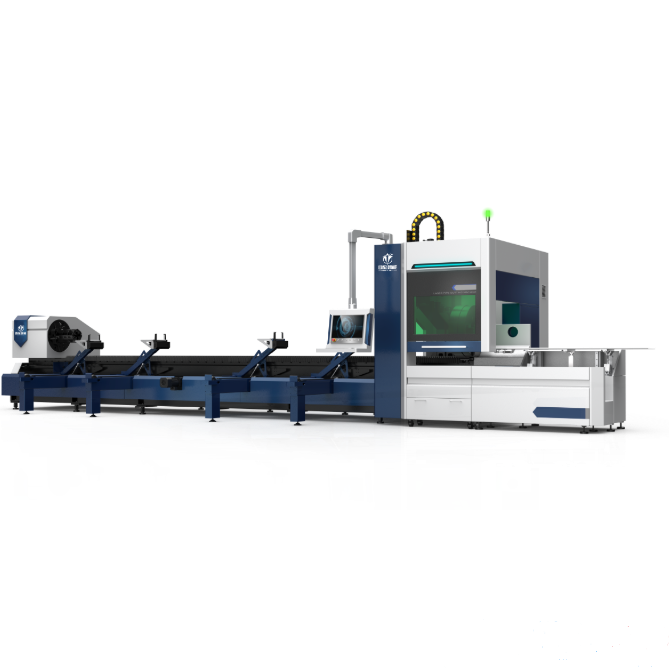

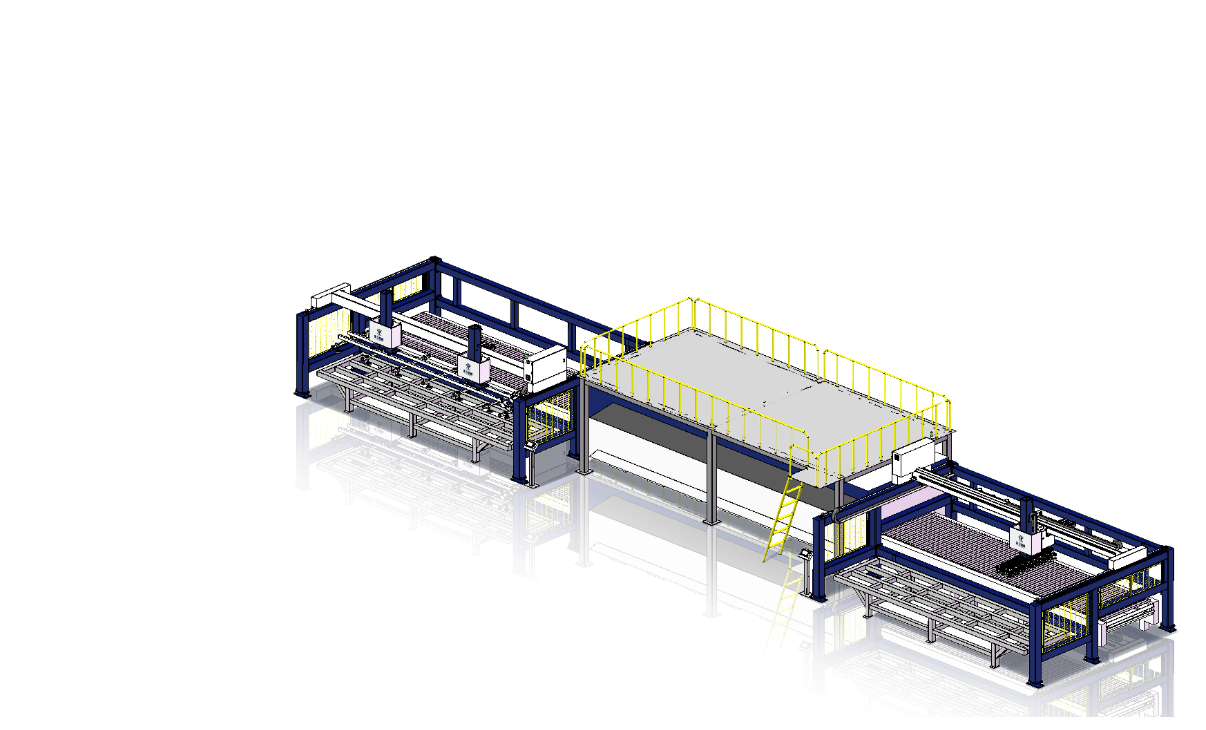

Our collaborative robotic welding station solves these problems perfectly. It has a highly automated operation process and can work 24 hours a day, greatly improving welding efficiency. The advanced programming system enables the robot to accurately perform a variety of complex welding tasks with stable and reliable welding quality, effectively reducing the defective rate. Meanwhile, the welding station also supports quick mold change and program switching, which can adapt to diversified production needs and save a lot of time and cost for enterprises.

Featured Application: Demonstration Mode

The demonstration mode of the Collaborative Robot Welding Station is a highlight. Staff can easily program it through simple operation. This intuitive operation does not require complex programming knowledge, lowering the skill threshold for operators and enabling even new employees to get started quickly. In addition, the demonstration mode also supports real-time modification and optimization of welding paths, making it easy for operators to make adjustments according to actual production needs, greatly improving production flexibility and adaptability.

Compared with traditional industrial robots, collaborative robots are flexible and easy to program, dramatically reducing demonstration and teaching time.

Program Advantages

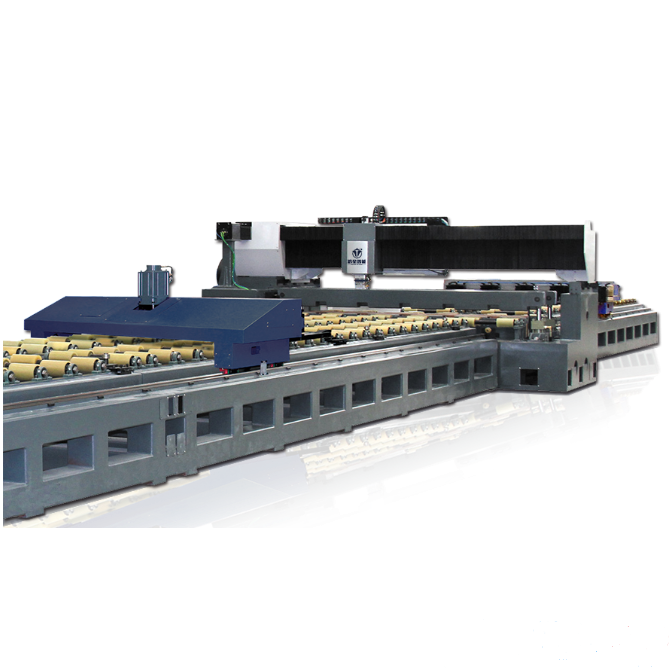

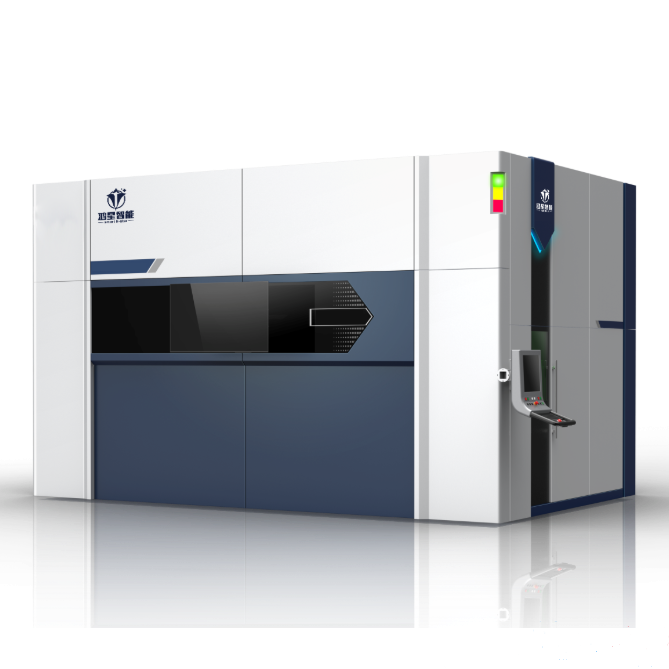

-High precision

Adopting advanced sensors and control systems, it is capable of achieving millimeter-level welding accuracy, ensuring consistency and stability of welding quality. Whether you are welding thin or thick plates, you can handle it with ease.

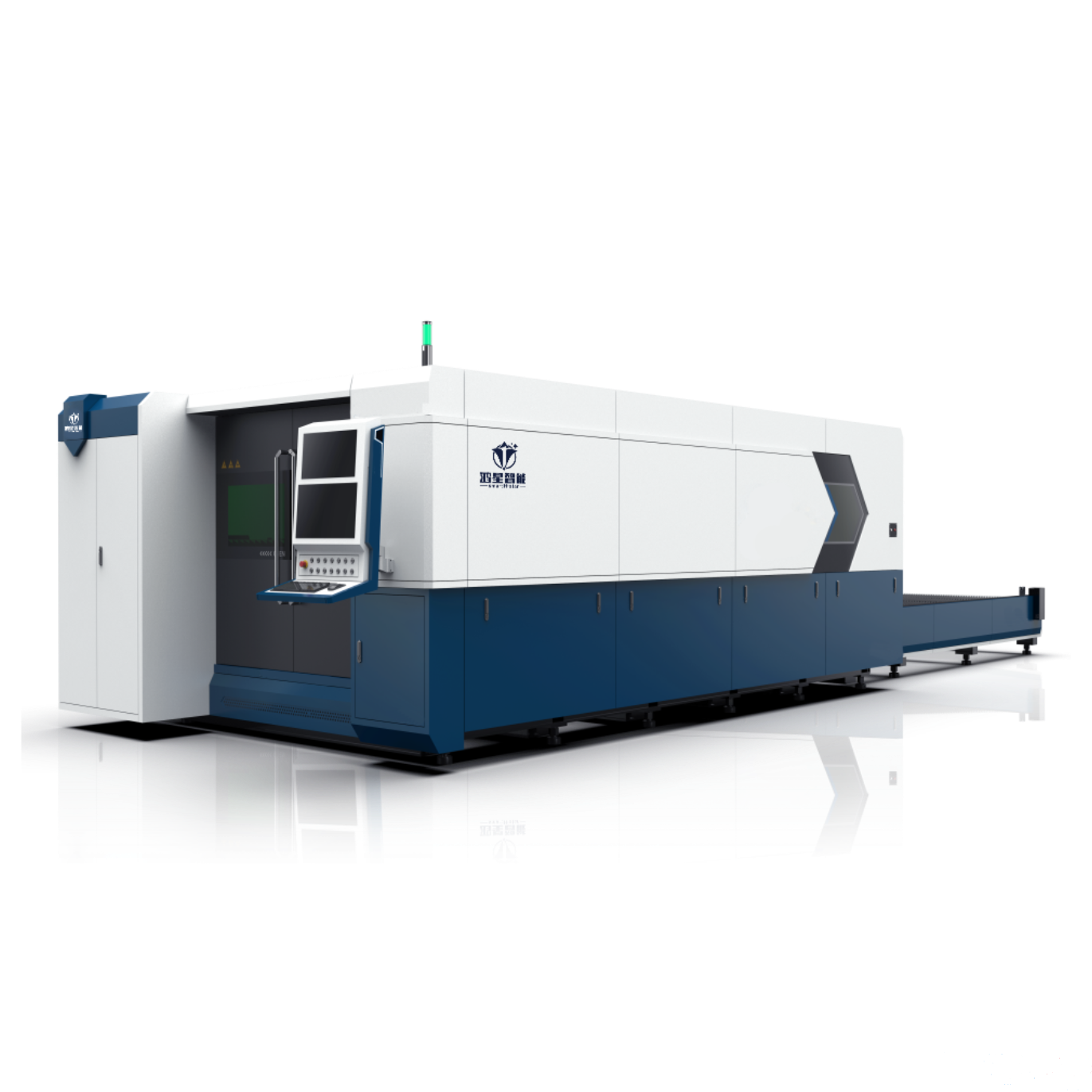

- Strong safety

Equipped with a variety of safety protection devices, such as collision detection and emergency stop button, it can effectively protect the safety of operators. Meanwhile, the collaborative design of the robot enables it to coexist safely with humans without the need to set up complicated safety fences, saving production space.

- Flexibility

It can be flexibly programmed and adjusted according to different welding tasks and workpiece shapes, making it suitable for a variety of complex welding scenarios. In addition, it supports integration with other automation equipment to realize fully automated production lines.

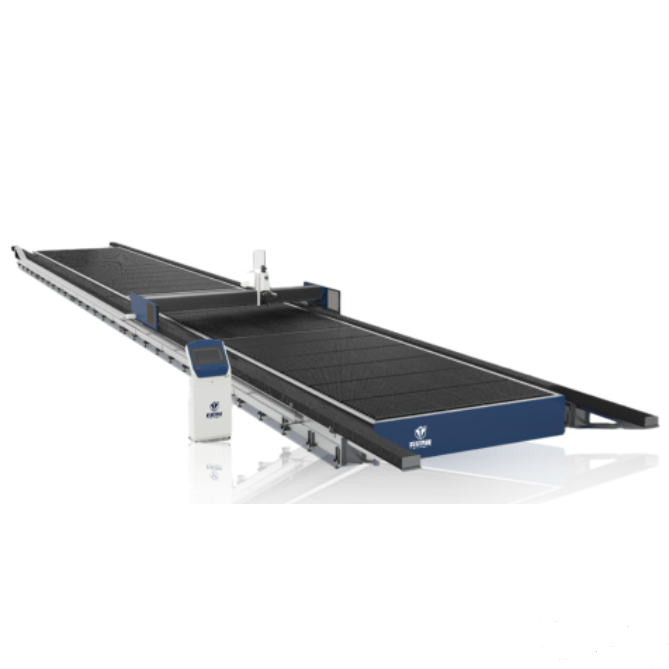

- Easy maintenance

The simple structure of the robot makes it easy to replace and maintain parts. At the same time, we provide perfect after-sales service and technical support to ensure the normal operation of the equipment, so that you have no worries.

Choose Us

- Lifetime technical support: provide process debugging, operation training, equipment maintenance one-stop services

- Machine warranty: core components can be extended to 2 years

- 24-hour response: cooperative service outlets throughout the country, quickly solve the problem on the spot.