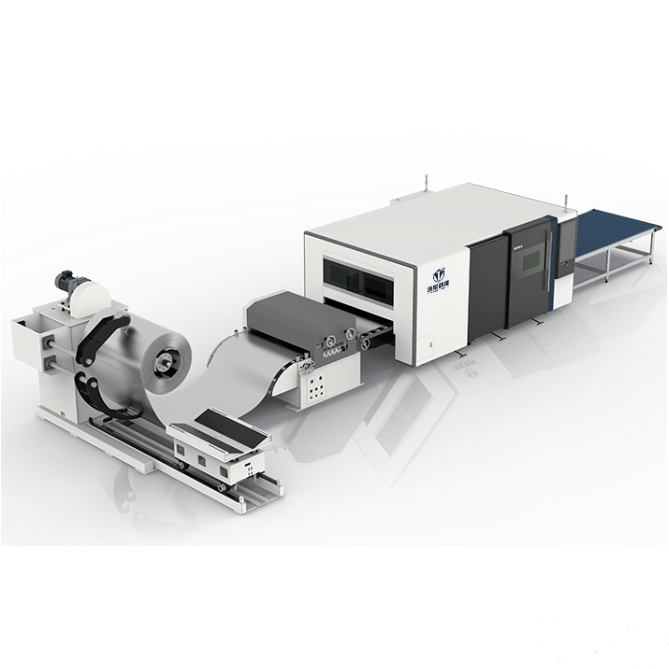

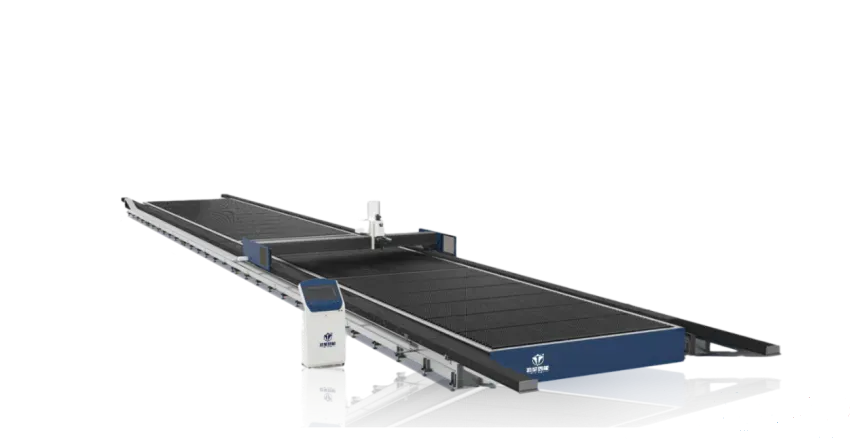

Hongxing Intelligent - Large format worktable laser cutting machine: a high-prec

Release Date:2025/04/09

Why are top manufacturing companies upgrading their laser cutting machines?

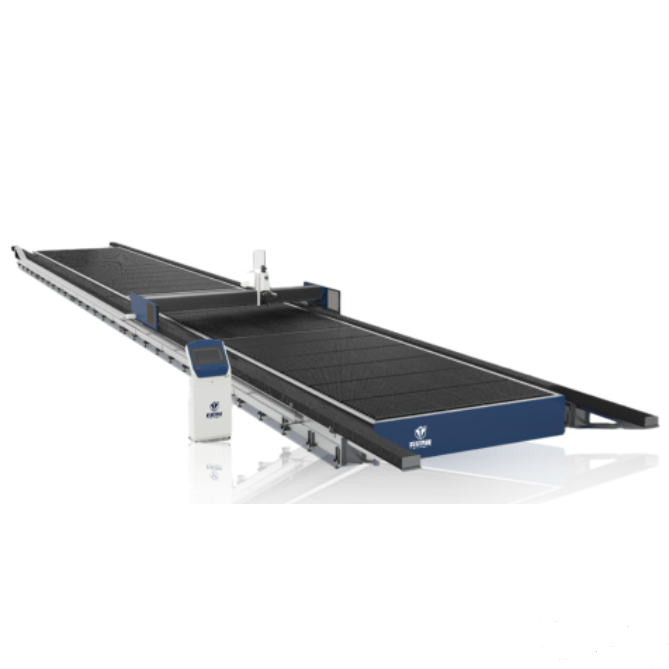

In the field of metal processing, precision, efficiency, and stability are the core elements that determine production capacity. Traditional equipment often experiences a decrease in yield due to thermal deformation, insufficient dust removal, or poor dynamic performance - and all of these are exactly the problems that our new large format workbench laser cutting machine aims to completely solve!

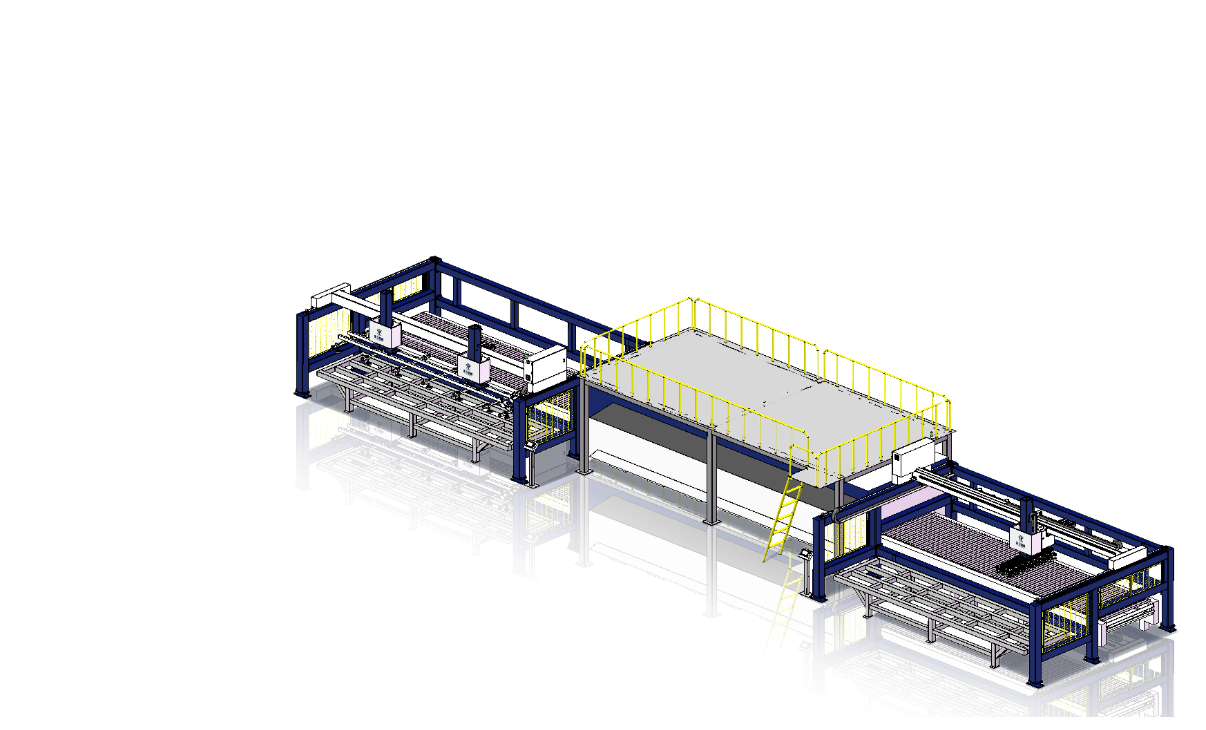

1、 Four core advantages define new industry standards

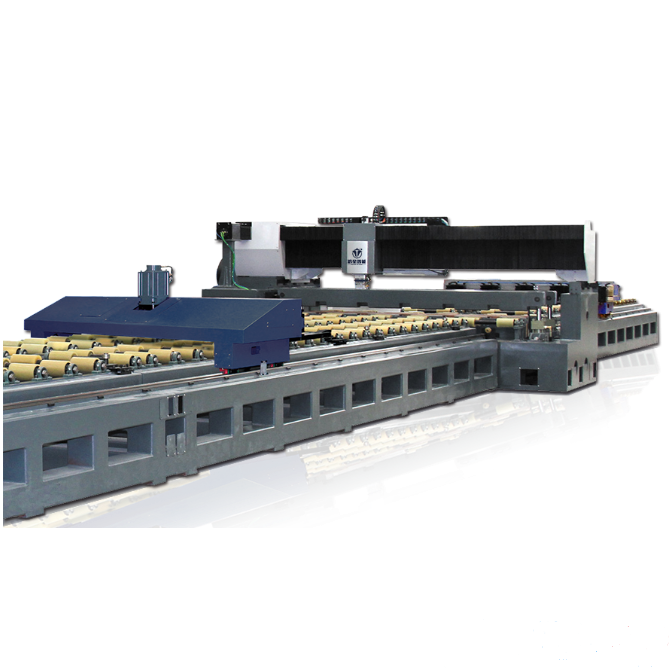

1️⃣Lightweight crossbeam+segmented structure=high precision without deformation

• Using high-strength steel plates to weld segmented bed bodies, completely avoiding the risk of welding deformation in long machine bodies

• The workbench is completely physically isolated from the bed, with insulation transmission, and can maintain a precision of ± 0.1mm even during continuous operation

• The combination of X-axis steel crossbeam and Z-axis cast aluminum increases rigidity by 30% and dynamic response speed by 20%

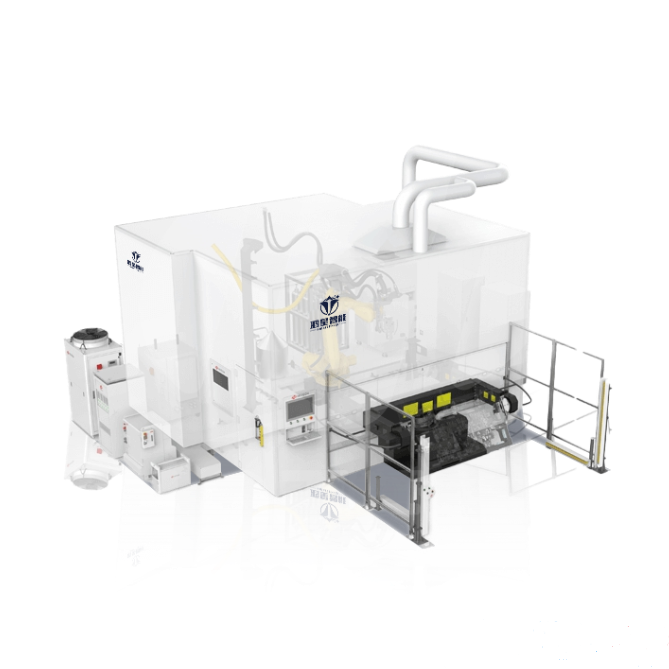

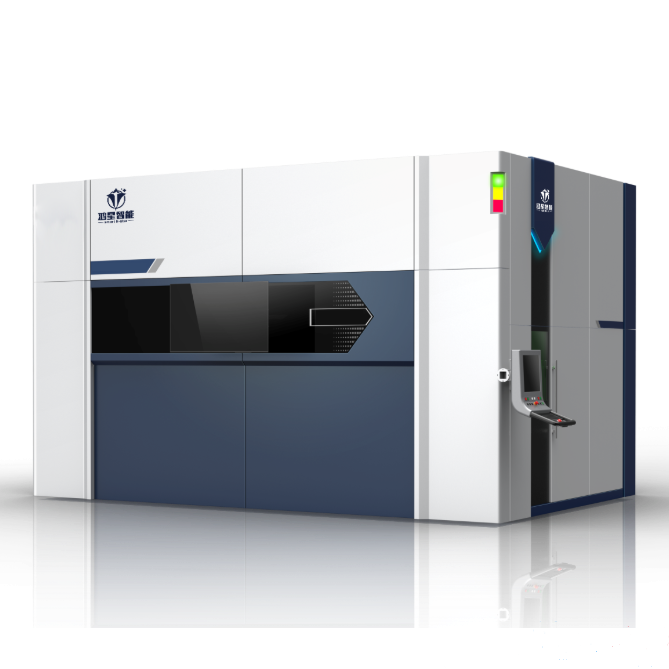

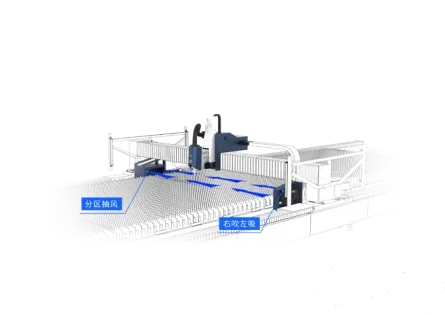

2️⃣Intelligent dust removal system: invisible dust, visible environmental protection

• Unique double-sided pneumatic zone dust removal, with a suction efficiency of 99% and a direct reduction of 90% in workshop PM2.5

• Hollow bed design with integrated air duct, automatic collection of debris, bidding farewell to manual cleaning time

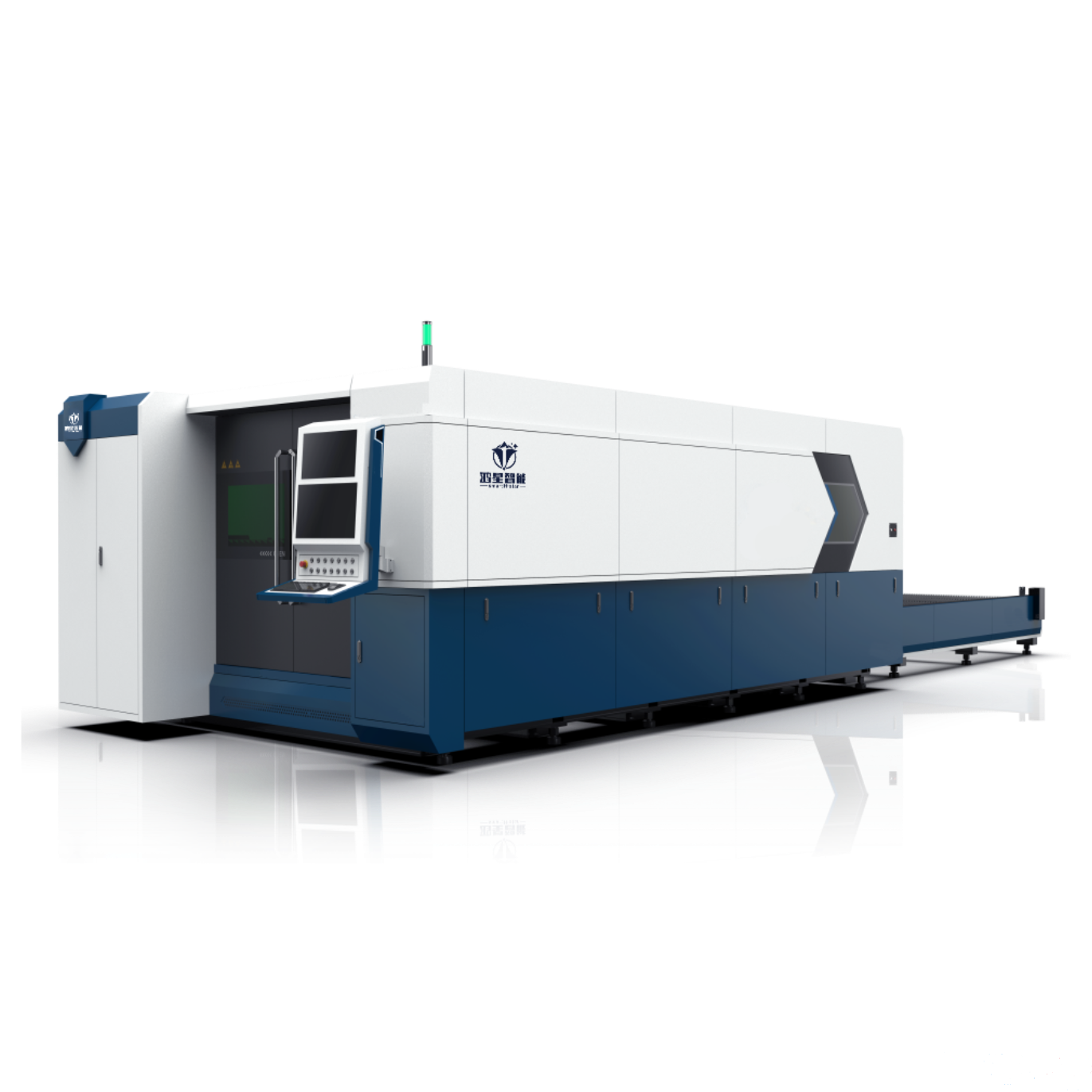

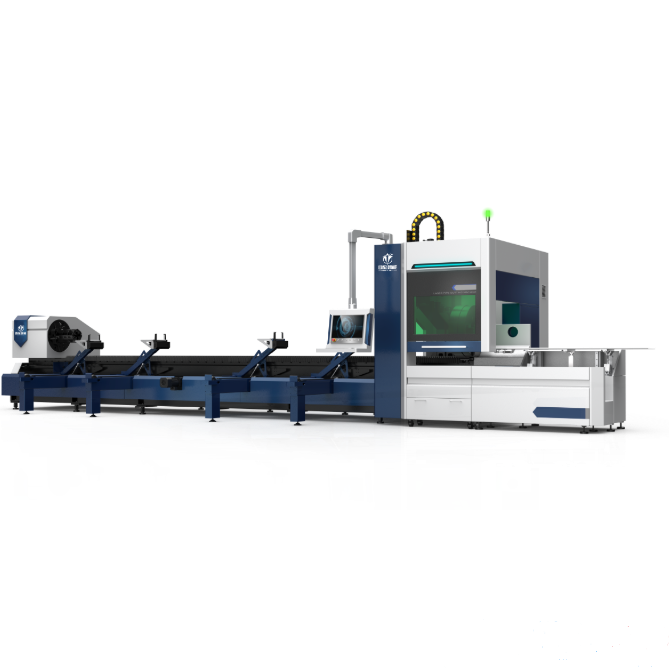

3️⃣Bus CNC system: Cutting is as simple as "printing"

• Support high-precision groove cutting, complete complex processes such as 45 ° bevel angle and V-groove in one go

• Motion control delay<1ms, complex graphic cutting speed increased by 35%

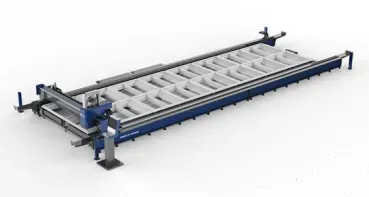

4️⃣Safety first: Light curtain protection+modular design

• Real time monitoring of X-axis dual end safety light curtain, immediate shutdown when human body approaches

• Segmented modular workbench, partial damage can be replaced separately, reducing maintenance costs by 60%

Customer feedback: "I thought changing the equipment would require production stoppage and break in, but I didn't expect to meet the standards on the same day of production. The accuracy of groove cutting even exceeded that of imported models

——A supplier of new energy vehicle components

Choose us

-Lifetime technical support: providing one-stop services for process debugging, operation training, and equipment maintenance

-Whole machine warranty: Core components can be extended to 2 years of warranty

-24-hour response: cooperative service outlets spread across the country, quickly solving on-site problems