【 Exhibition Review 】 Hongxing Intelligent Collaborative Welding Robot Shines at

Release Date:2025/06/27

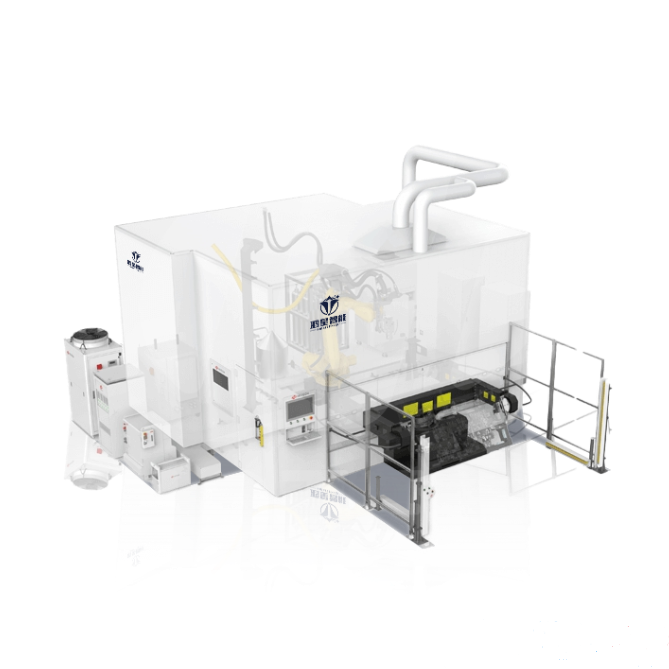

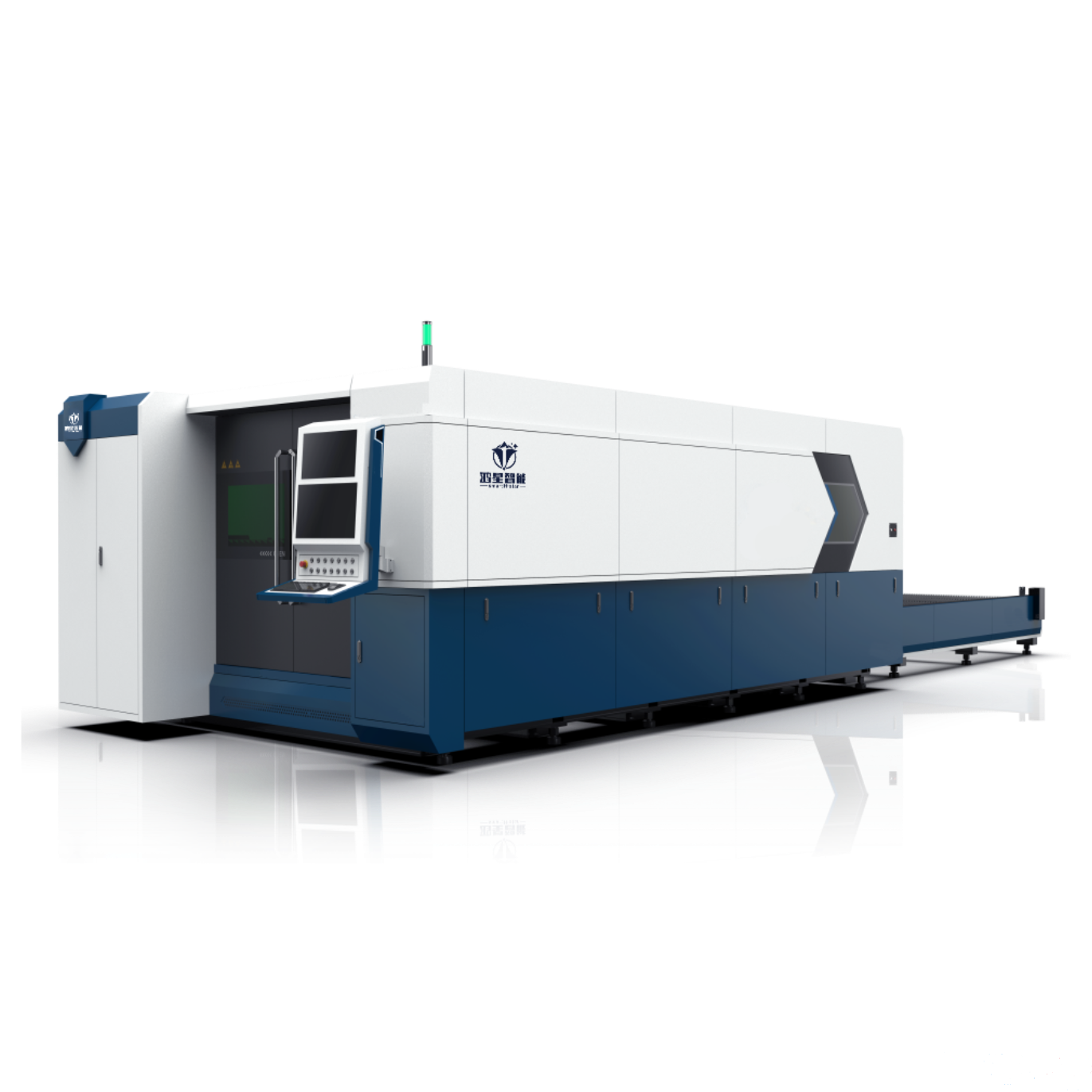

At the just concluded 28th Qingdao International Machine Tool Exhibition, Hongxing Intelligent's latest collaborative welding robot became the focus of the event with its cutting-edge technology concept and excellent on-site demonstration performance, attracting extensive attention from industry experts, enterprise representatives, and media. At this exhibition, we not only showcased the high performance of collaborative welding robots, but also interpreted the core value of "human-machine collaboration, intelligent manufacturing of the future" through deep interaction with the audience.

Review of Exhibition Highlights

1. Human machine collaboration, safe and efficient

At the exhibition site, the collaborative welding robot demonstrated directly with engineers in a fence free operation mode. Its high-sensitivity force control system and real-time collision detection function allowed the audience to intuitively feel the safety - even if accidentally touched, the robot would stop instantly, ensuring zero risk for personnel. This feature is particularly favored by small and medium-sized enterprises, solving the pain point of traditional welding automation that requires isolation and protection.

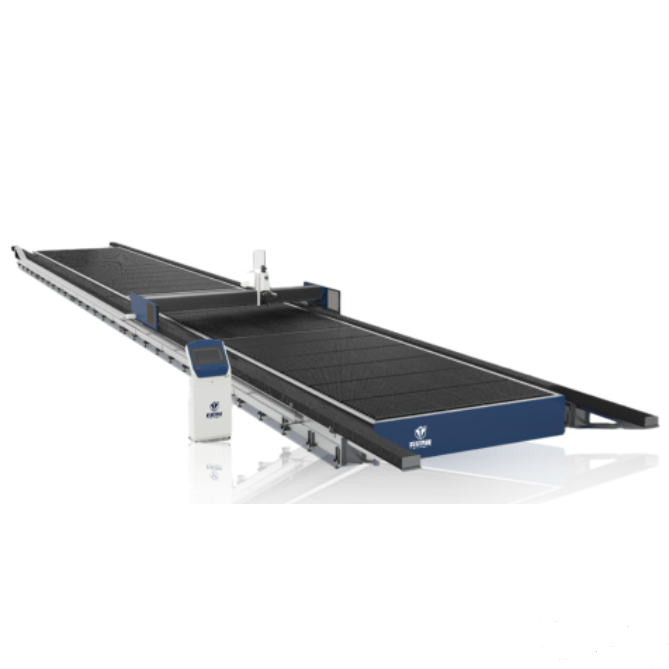

2. Zero threshold operation, quick deployment

Through drag and drop demonstrations and a graphical programming interface, the on-site audience personally experienced the convenient operation of "setting the welding path in 3 minutes". A viewer who had never been exposed to robots completed a soldering process in just 5 minutes under the guidance of an engineer, fully verifying the usability of the product.

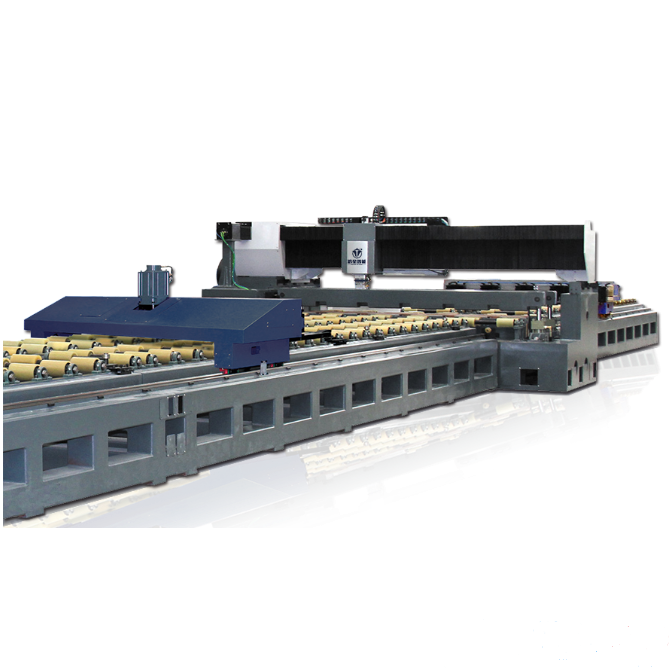

3. Adaptive welding, precise and stable

In response to the common issue of workpiece deviation in the welding industry, the robot's visual correction system and intelligent parameter adjustment function demonstrated its dynamic compensation capability on site. Even if there is a ± 5mm error in the placement position, the robot can still accurately track the weld seam, ensuring process consistency and winning praise from professional audiences.

4. Scenario based solutions spark heated discussions

The exhibition booth features two real-life workstations for welding components and multi process welding of irregular parts, showcasing the robot's ability to flexibly adapt to different welding guns. Representatives from multiple manufacturing companies consulted on-site to explore how to apply it to their own production line upgrades.

Industry feedback: Change has arrived, win-win cooperation

This collaborative robot perfectly solves our welding needs for small batches and multiple varieties, with deployment costs 50% lower than traditional solutions, "said the technical director of a certain automotive parts manufacturer

Expert from Welding Association: "It lowers the threshold for automation and provides a feasible intelligent path for small and medium-sized enterprises

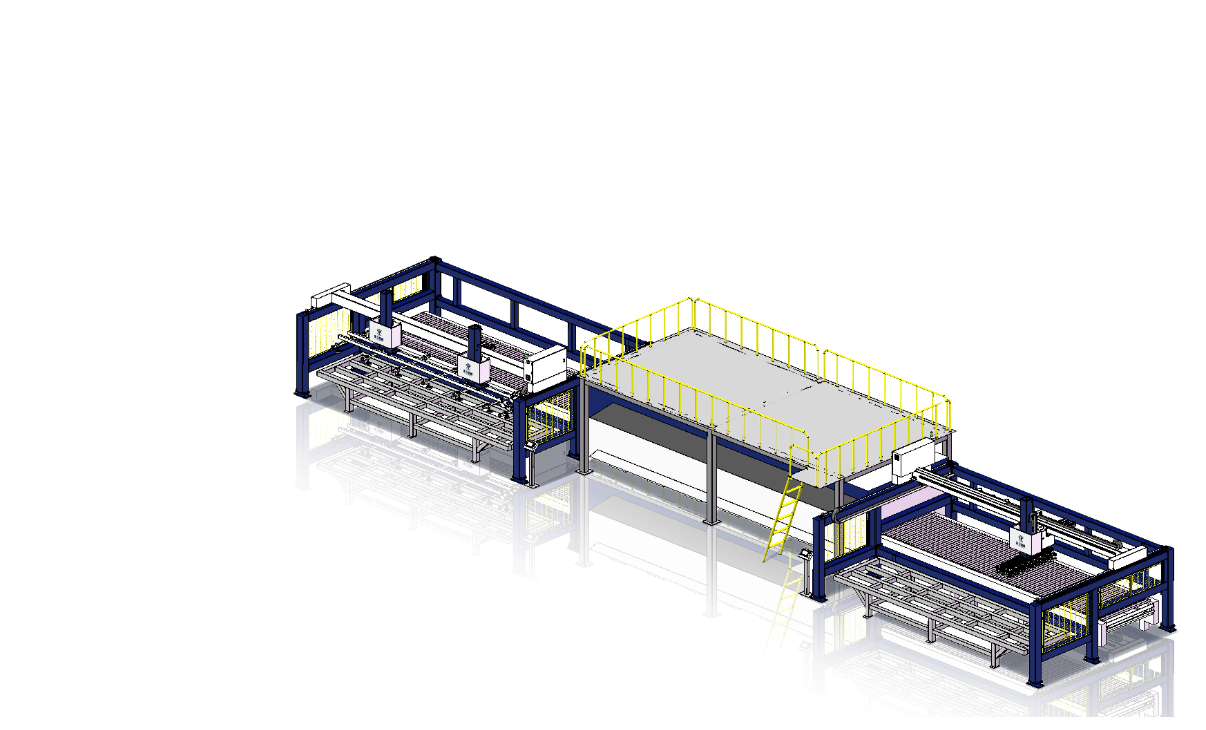

Hongxing Intelligent Collaborative Robot Welding Samples at Customer Sites

look into the future

This exhibition is not only a showcase of products, but also a dialogue on industry trends. Hongxing Intelligence will continue to deepen its cultivation of intelligent manufacturing technology, promote the popularization of "safe, civilian, and high-precision" intelligent welding solutions, and assist in the transformation and upgrading of the global manufacturing industry.

Although the exhibition has ended, the service is always online

Choose us

-Lifetime technical support: providing one-stop services for process debugging, operation training, and equipment maintenance

-Whole machine warranty: Core components can be extended to 2 years of warranty

-24-hour response: cooperative service outlets spread across the country, quickly solving on-site problems