Ushering in the spring breeze, high-power laser-arc composite welding technology

Release Date:2024/07/30

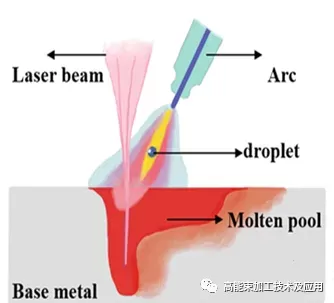

Thick plate (thickness ≥20mm) welding plays a key role in large-scale equipment manufacturing in important fields such as aerospace, Marine ships, rail transit, etc. These components are usually characterized by large thickness, joint form and complex service environment. Welding quality has a direct impact on the performance and life of the equipment. Because of the slow welding speed and serious spatter problem, the traditional gas-protected welding method has the challenges of low welding efficiency, high energy consumption and large residual stress, which is difficult to meet the increasing manufacturing requirements. However, unlike traditional welding technology, laser-arc composite welding technology successfully combines the advantages of laser welding and arc welding, and has the characteristics of large penetration, fast welding speed, high efficiency and better weld quality, as shown in Figure 1. Therefore, this technology has attracted wide attention and has begun to be applied in some key areas.

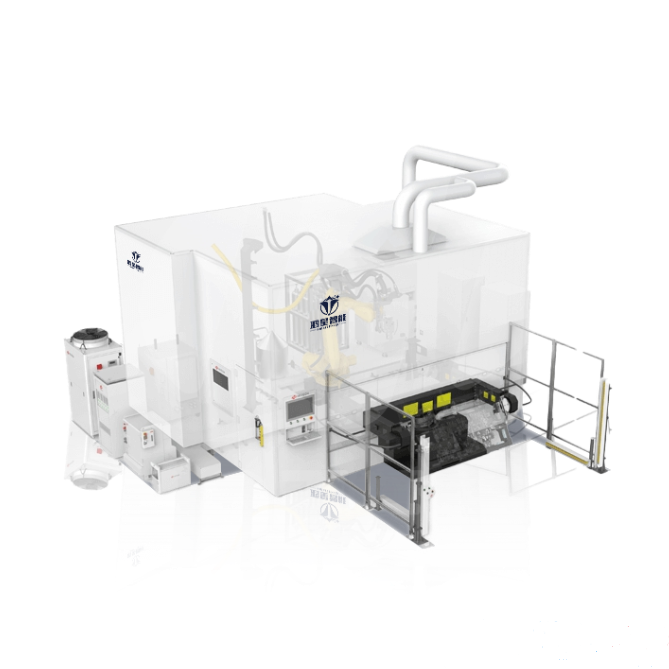

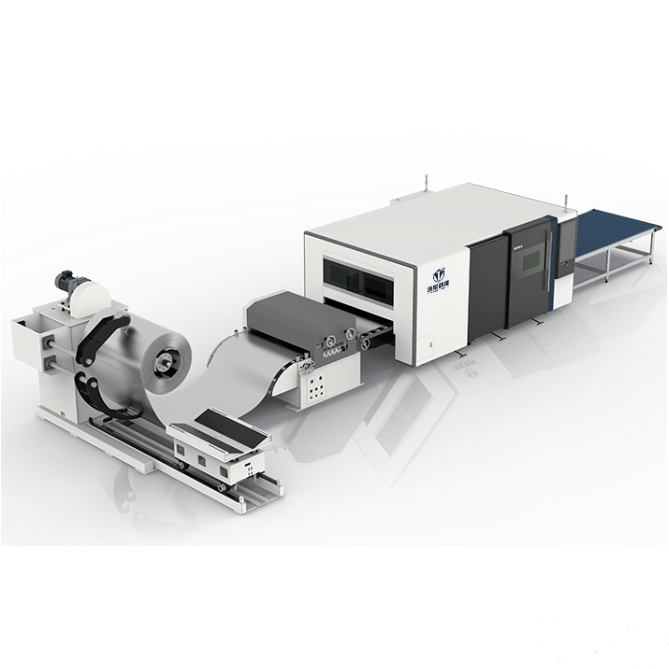

图1 激光-电弧复合焊接原理

Study on laser-arc composite welding of thick plate

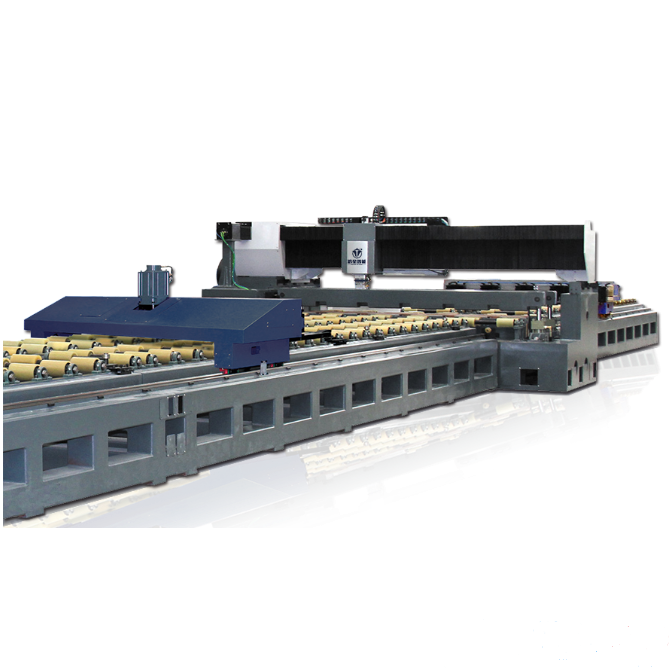

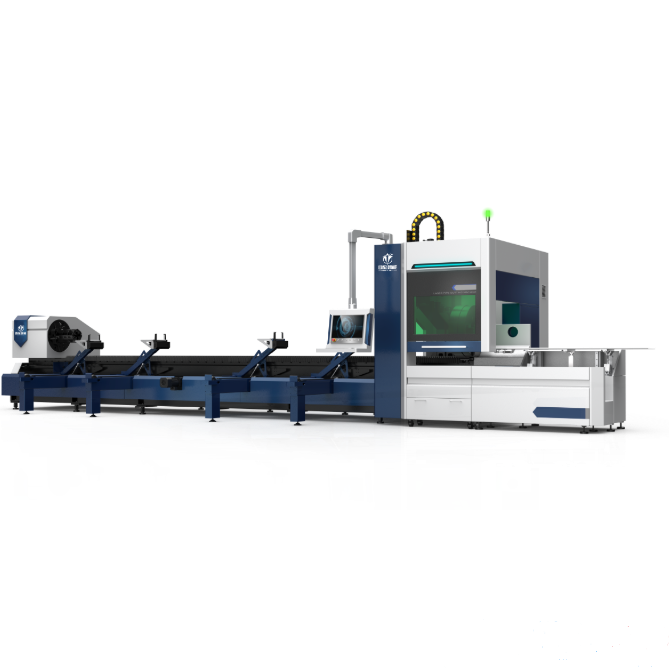

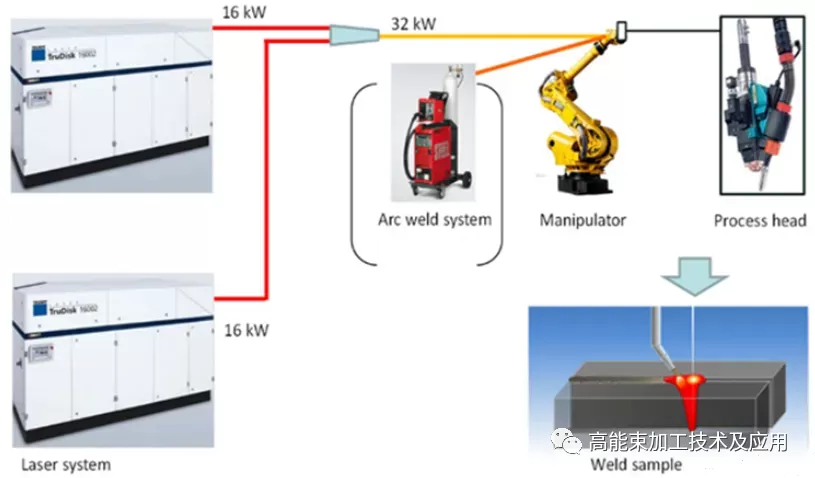

The microstructure uniformity of the composite welded joint of 45mm thick microalloy high strength low alloy steel was studied by the Norwegian Institute of Industrial Technology and the Lule University of Technology in Sweden at 15kW. Osaka University and Egypt Central Metallurgical Research Institute used 20kW fiber laser to carry out research on thick plate (25mm) single-channel laser-arc composite welding technology, and adopted the bottom liner to solve the bottom hump problem. Force Technology, a Danish company, used two 16 kW disc lasers in series to carry out the research on the composite welding process of 40mm thick steel plate at 32kW, indicating that high-power laser-arc welding is expected to be applied to the welding of offshore power tower, as shown in Figure 2. Harbin Welding Institute has taken the lead in mastering the core technology and equipment integration technology of high-power solid-state laser-melt-electrode arc composite heat source welding, and successfully applied the high-power solid-state laser-double wire melt-electrode arc composite welding technology and equipment to China's high-end equipment manufacturing industry for the first time.

Figure 2 Laser installation layout

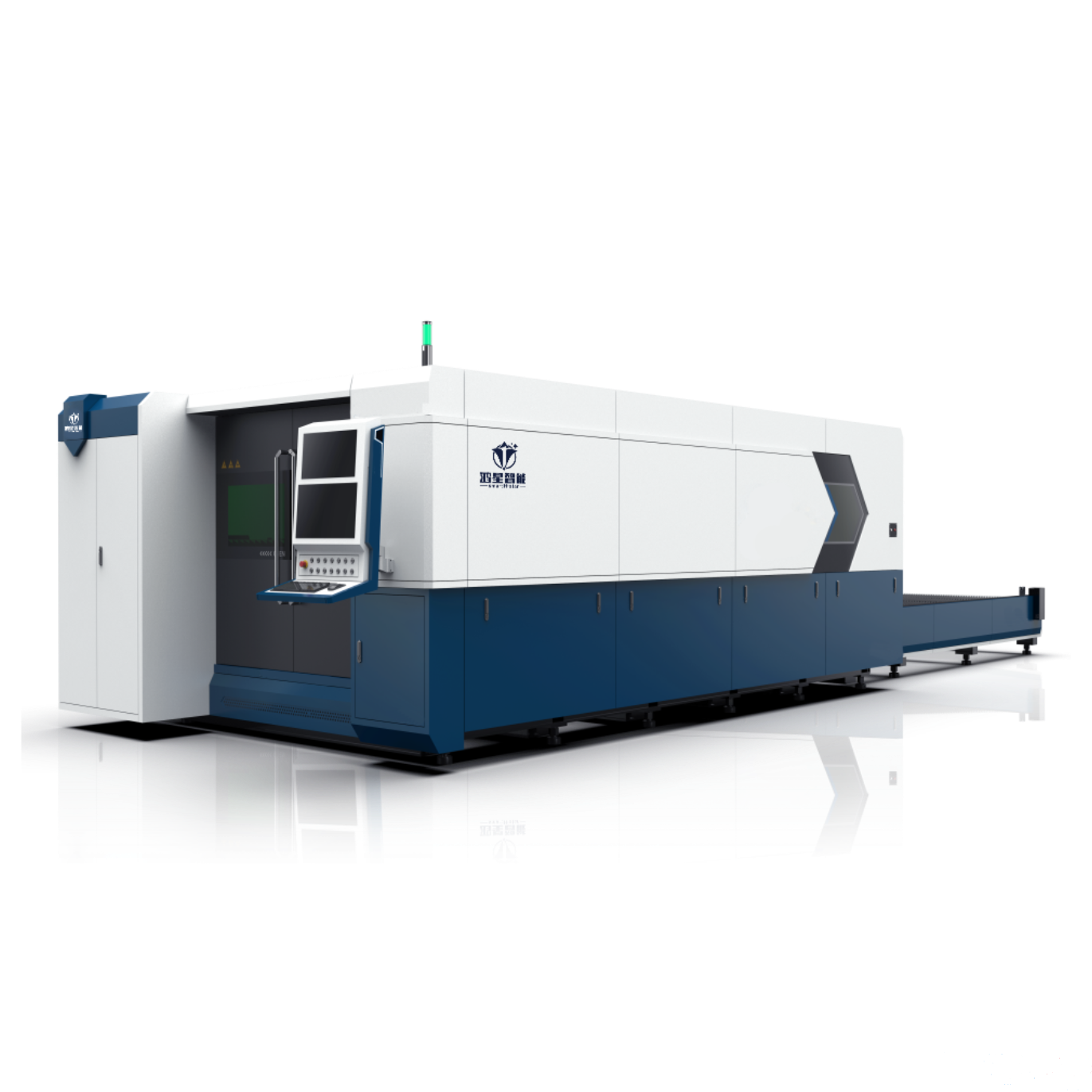

Application of high power laser-arc composite welding

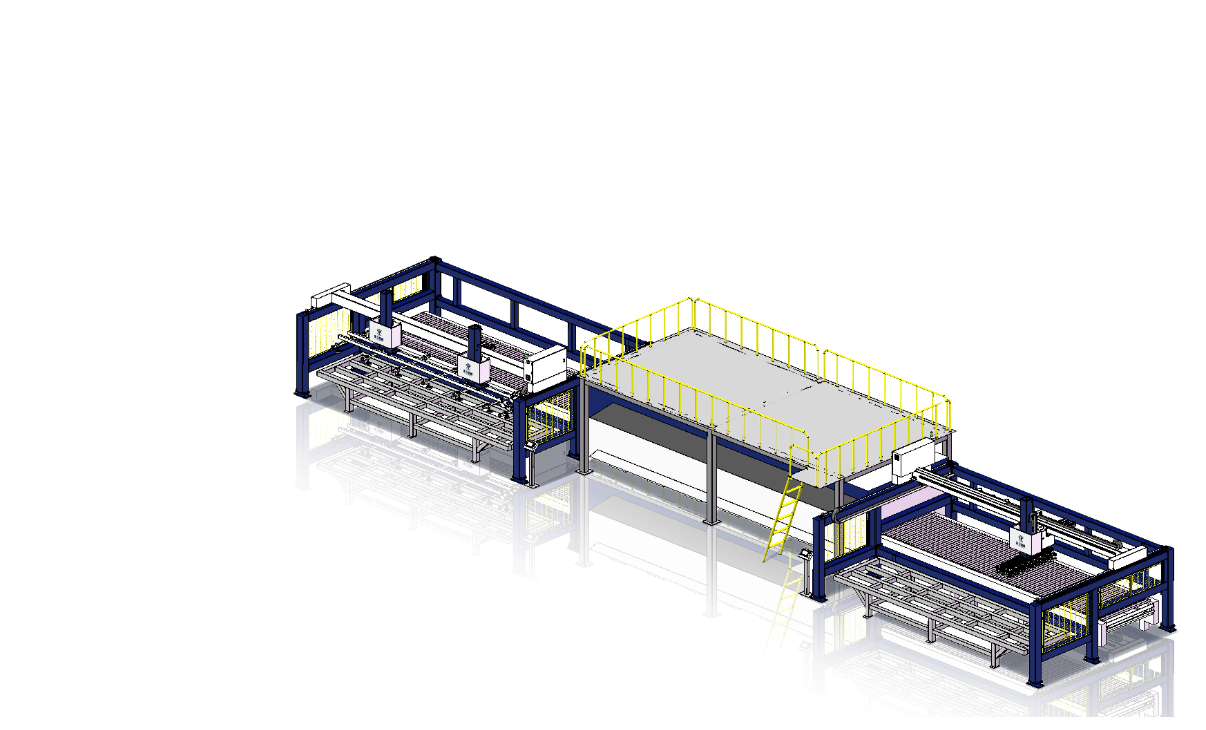

High power laser-arc composite welding technology is widely used in Marine industry. German Meyer shipyard established 12kW CO2 laser-arc composite welding production line for hull plate and reinforcement welding, to achieve a 20m long fillet weld forming, deformation degree reduced by 2/3. GE developed a fiber laser-arc composite welding system with a maximum output power of 20kW to weld the U.S. aircraft carrier Sara toga, saving 800 tons of weld metal and reducing 80% of working hours, as shown in Figure 3. The 20kW fiber laser high-power laser-arc composite welding system used in CSSC 725 can reduce welding deformation by 60% and increase welding efficiency by 300%. Shanghai Waigaoqiao Shipyard adopts 16kW fiber laser high-power laser-arc composite welding system, the production line adopts the new technology of laser composite welding +MAG welding, and realizes the single-side single-pass welding double-sided forming of 4-25mm thick steel plate. High power laser-arc composite welding technology has been widely used in armored vehicles, and its welding characteristics are: large thickness complex metal structure welding, low cost, high efficiency manufacturing.

Figure 3. Aircraft carrier USS Sara toga

conclusion

High power laser-arc composite welding technology has been applied in some industries, and will become an important means of efficient manufacturing of large structures with large wall thickness. At present, there is a lack of research on the mechanism of high-power laser-arc composite welding, which needs to be further strengthened, such as the interaction between photoplasma and arc and the interaction between arc and molten pool. There are still many unsolved problems in high power laser-arc composite welding process, such as narrow process window, uneven mechanical properties of weld tissue, and complex welding quality control. With the gradual increase of output power of industrial lasers, high-power laser-arc composite welding technology will develop rapidly, and a variety of new laser composite welding technologies will continue to emerge. Localization, large-scale and intelligent will be an important trend in the development of high-power laser welding equipment in the future.