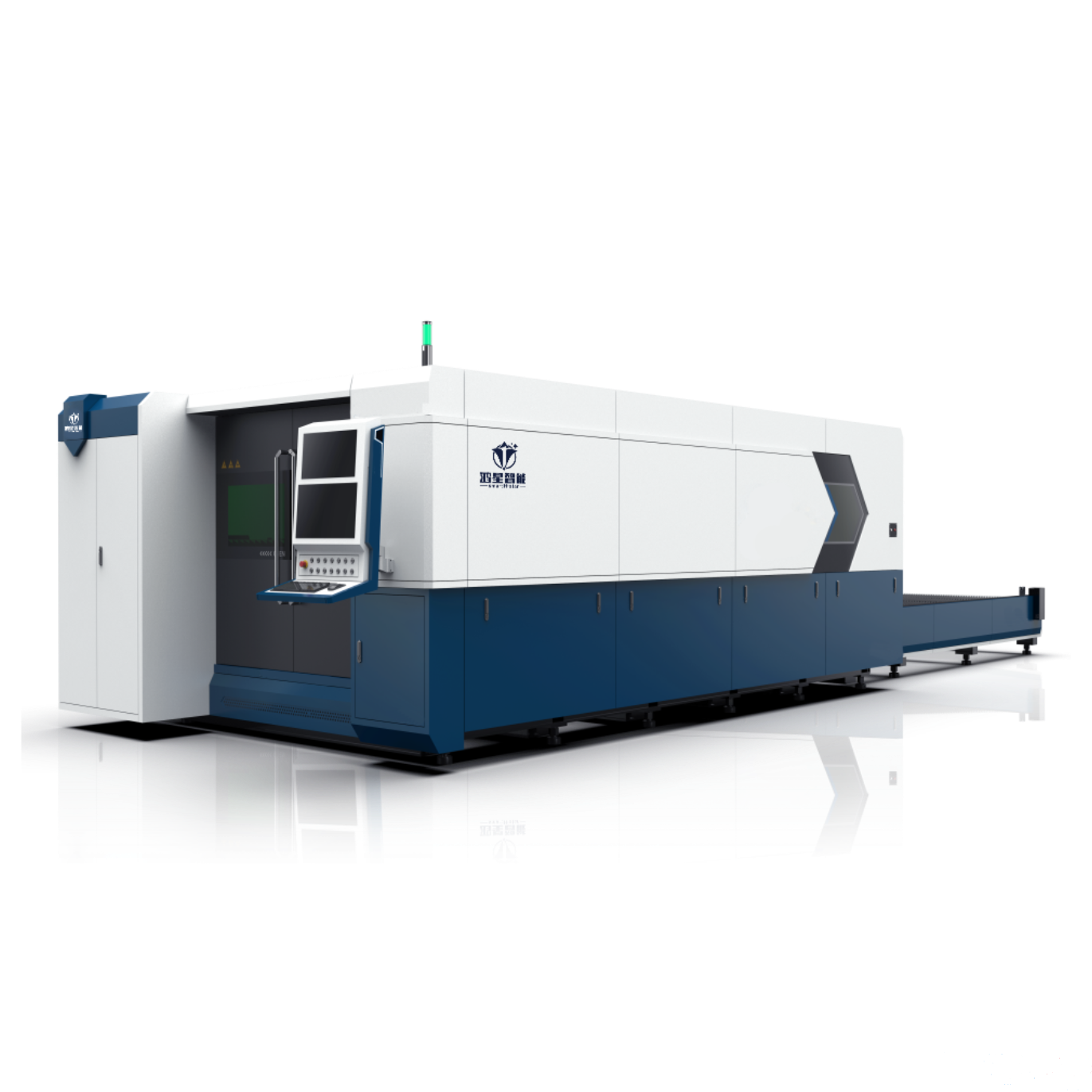

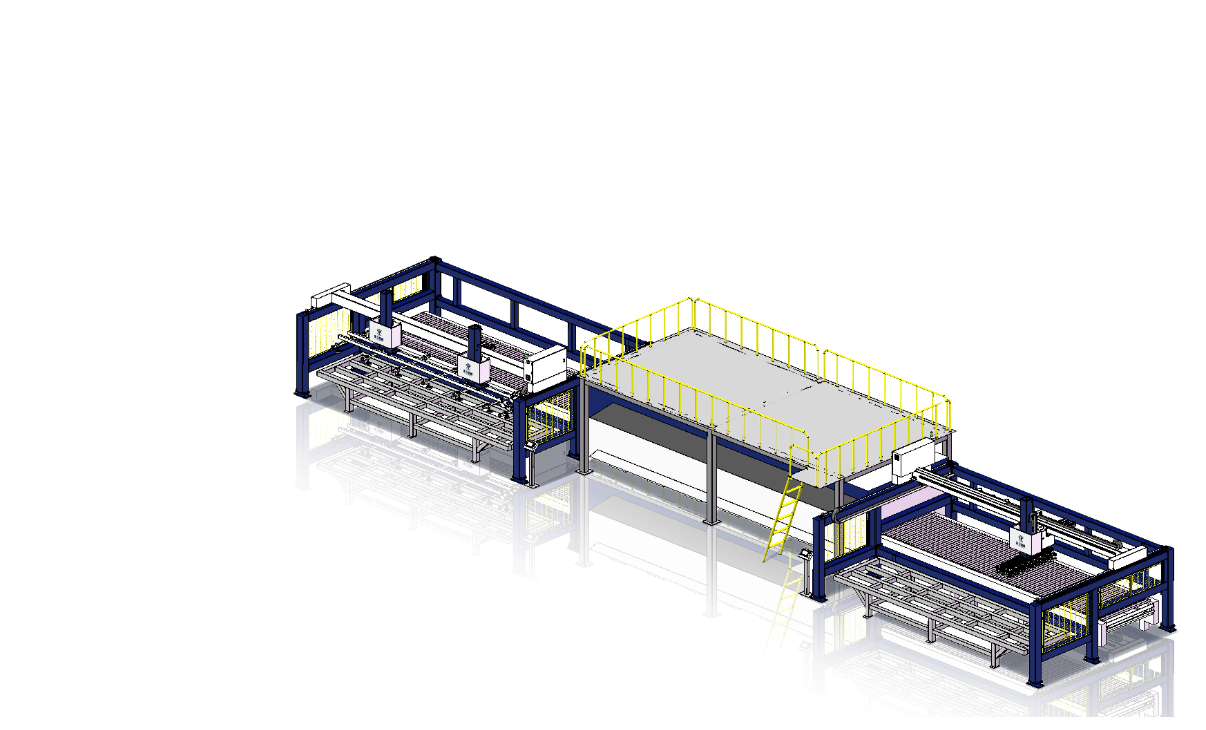

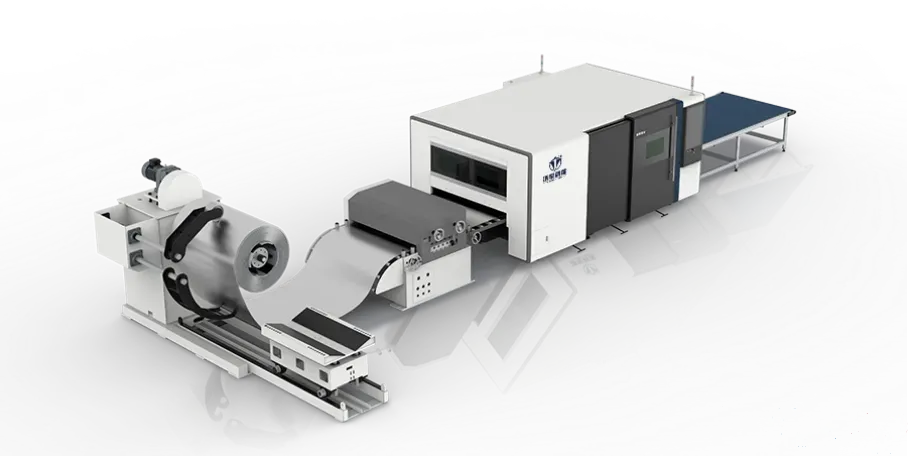

Hongxing Intelligent - Newly upgraded coil laser cutting machine! One stop coil

Release Date:2025/05/23

Newly upgraded, cutting efficiency increased by 300%

Still struggling with the low efficiency and complicated processes of traditional cutting machines?

Hongxing Intelligent's new generation of coil laser cutting machine makes a stunning debut!

Fully automated integration of unwinding, feeding, cutting, and unloading, with 24-hour continuous operation, resulting in a 300% increase in efficiency!

Four core functions, subverting traditional processing modes

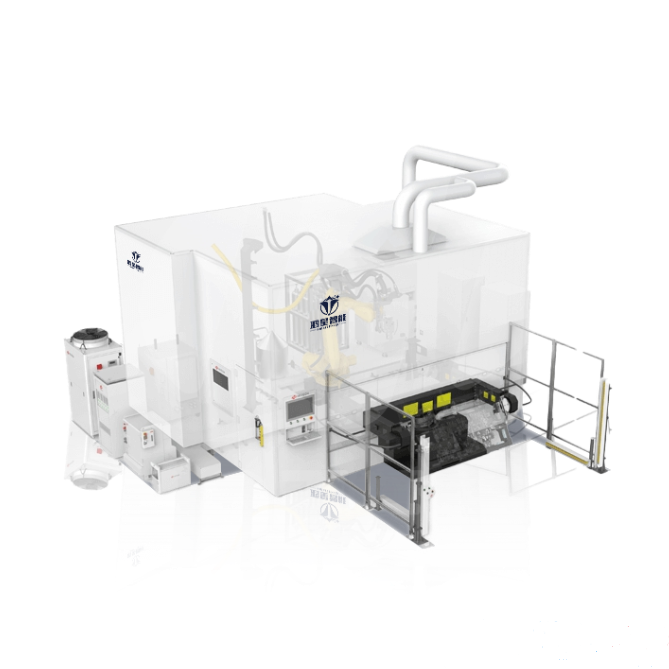

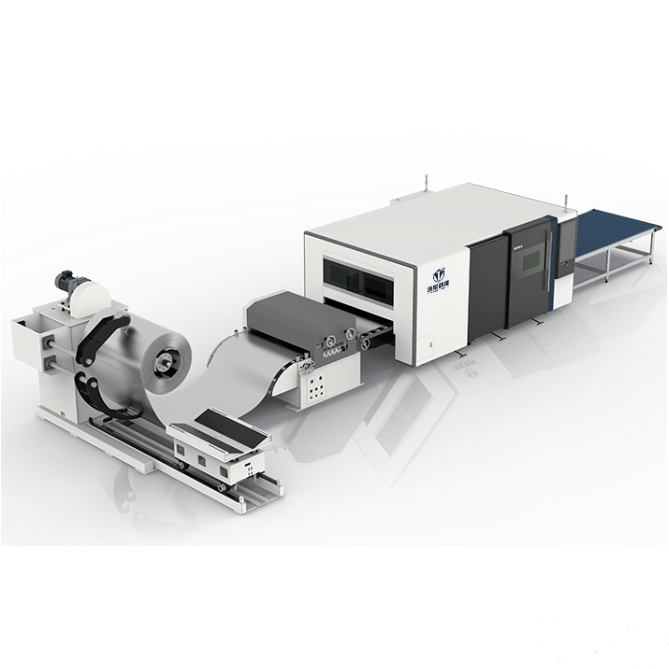

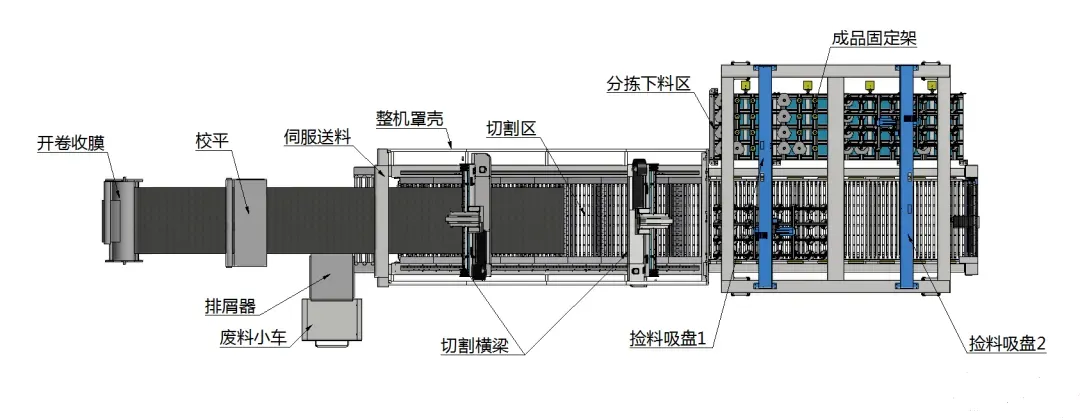

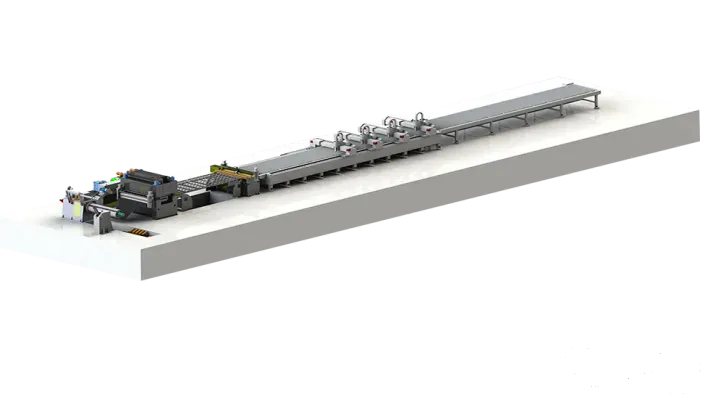

① One stop processing production line

Integrate the four major processes of unwinding, feeding, cutting, and unloading, bid farewell to single machine operation, and achieve full process automation!

② Automatic sorting and unloading of materials

Intelligent recognition, precise sorting, eliminating manual handling, improving both efficiency and accuracy!

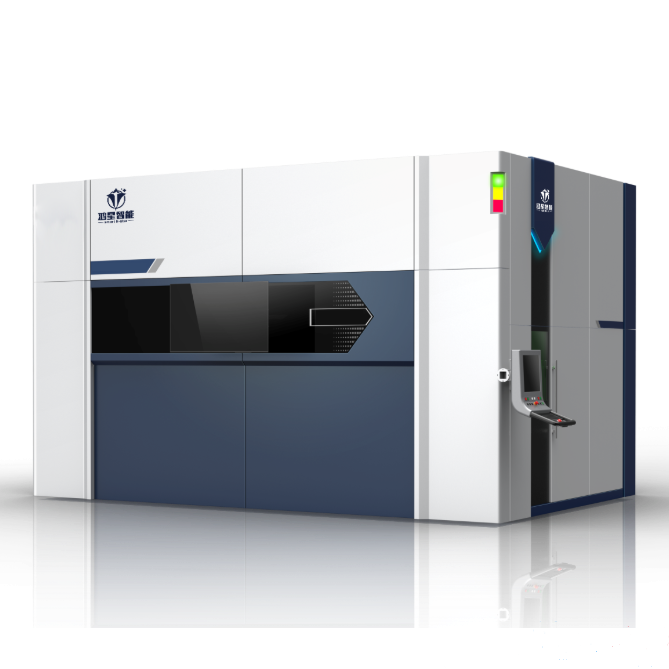

③ Multi process fusion design

Built in paper collection, laminating, and waste collection mechanisms reduce equipment footprint and optimize production processes!

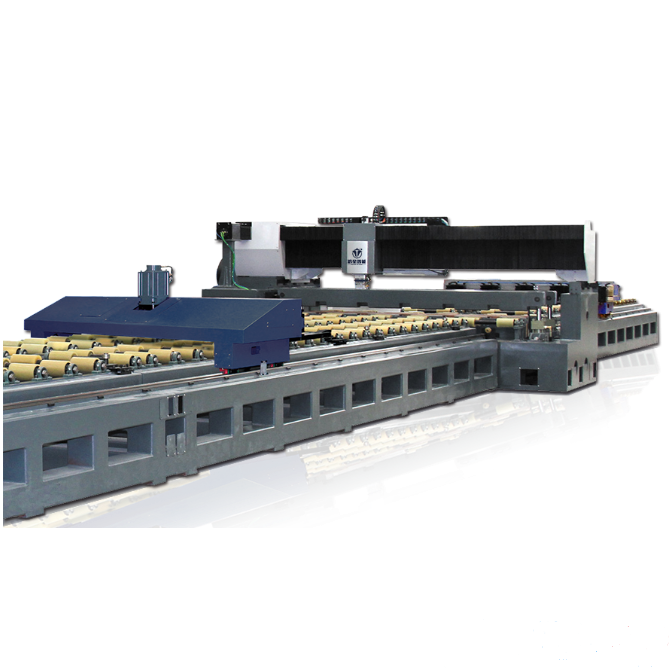

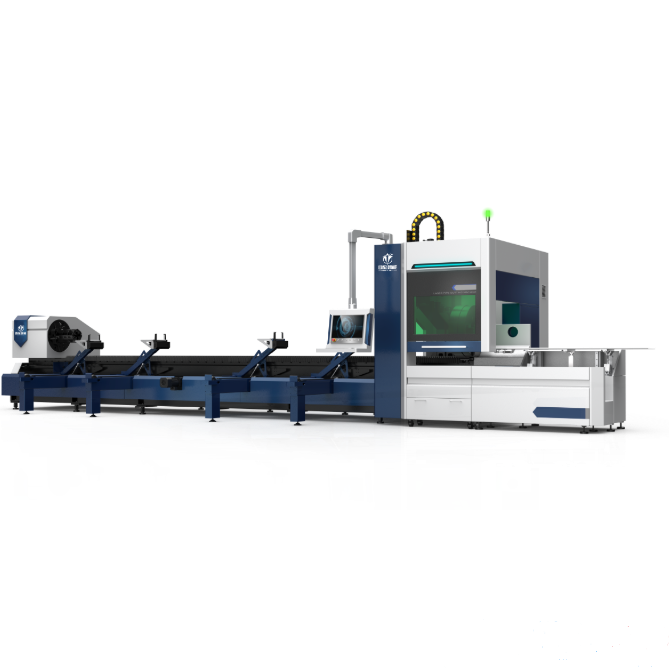

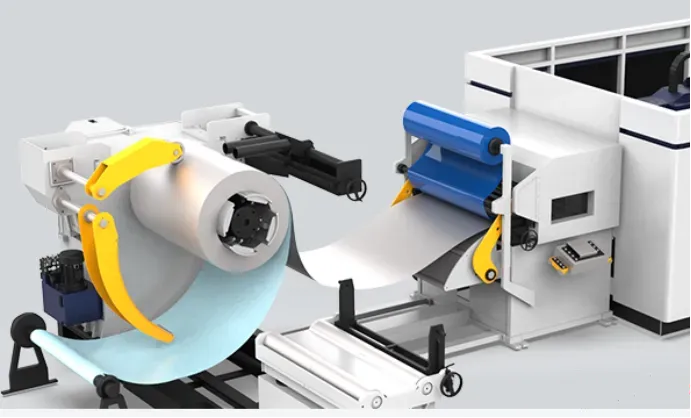

④ Multi roll intelligent switching

Multiple unwinding racks can be freely switched, seamlessly connecting different rolls, ensuring uninterrupted production!

The characteristics of the four major models create ultimate efficiency

✔ Continuous cutting, doubling efficiency

The roll material is transported continuously for 24 hours, with synchronous feeding and discharging, and the production efficiency is directly maximized!

✔ Heavy material rack, stable as Mount Tai

Cantilever structure+stress annealing process, with super strong load-bearing capacity;

Variable frequency control+hydraulic expansion, smooth discharge, flexible operation!

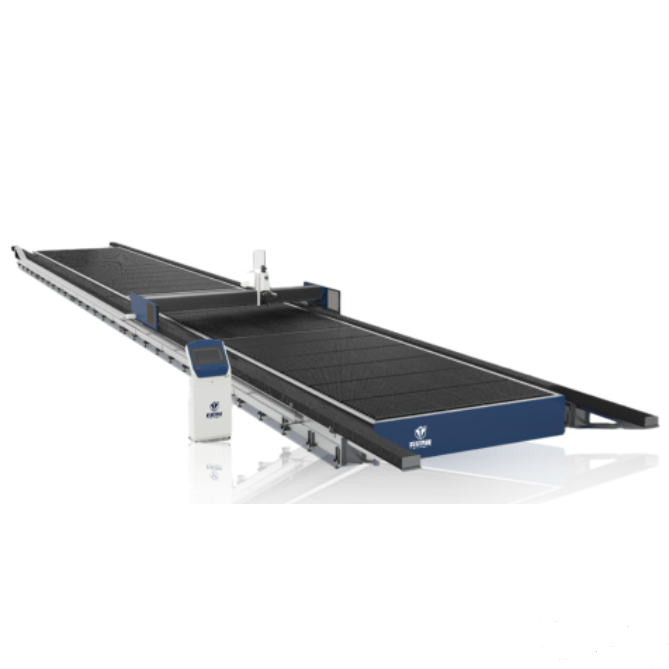

✔ Leveling and stress relief for smoother cutting

Exclusive leveling technology eliminates internal stress in the board, ensuring flatness and making every cut clean and sharp!

✔ Laser cutting, material saving and efficient

High precision laser cutting increases speed by 50%, maximizes sheet utilization, and further reduces costs!

Application scenarios

✔ Sheet Metal Fabrication

✔ Automotive parts manufacturing

✔ Home appliance manufacturing

It can handle all the cutting needs of coil materials!