Hongxing Intelligent - Profile Laser Cutting Machine: Efficient and versatile, a

Release Date:2025/06/03

Traditional profile processing requires multiple processes such as marking, drilling, groove cutting, and polishing, which are not only time-consuming and labor-intensive, but also prone to errors. This is a common problem that troubles many manufacturers. How to achieve efficient, precise, and one-stop processing?

The answer is here - profile laser cutting machine!

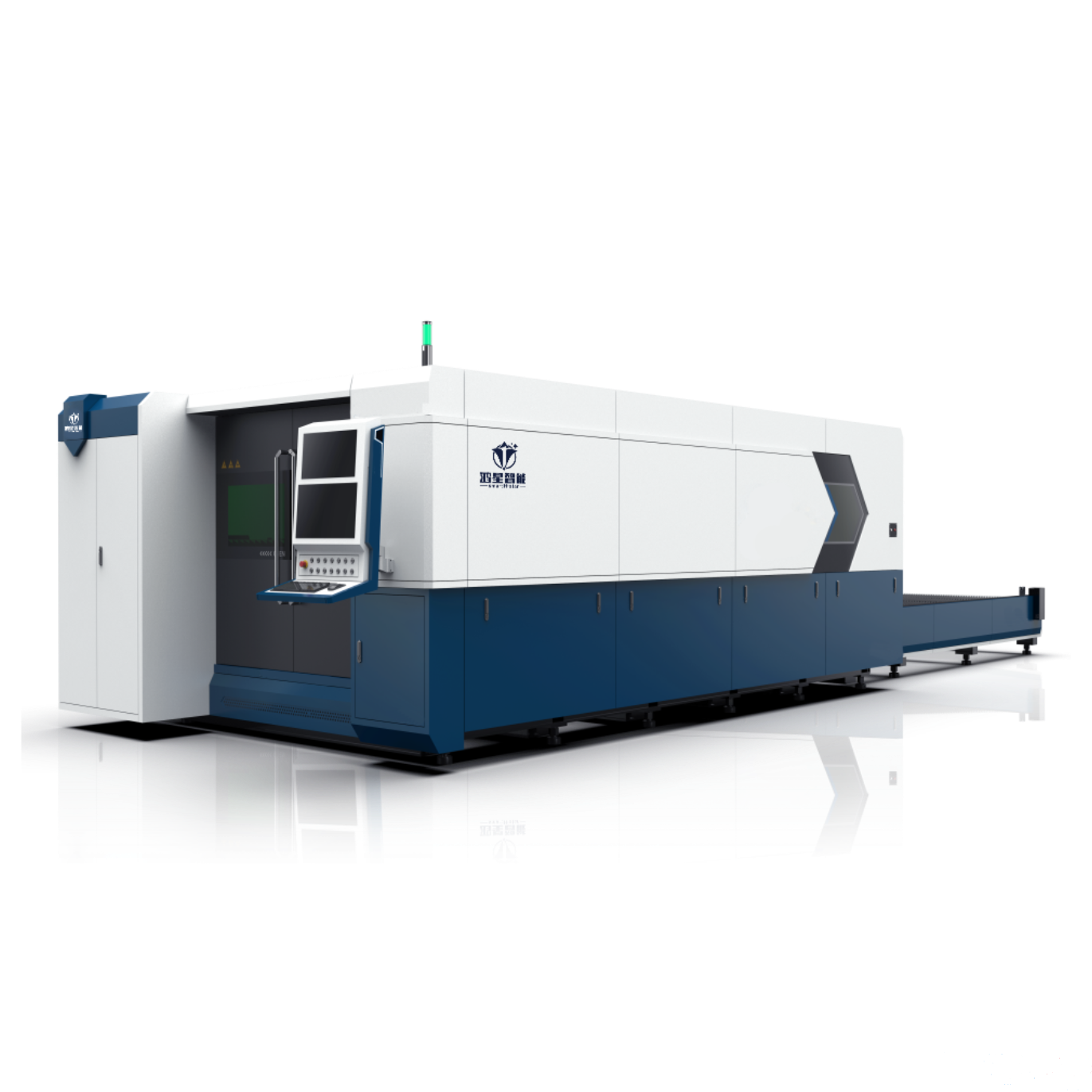

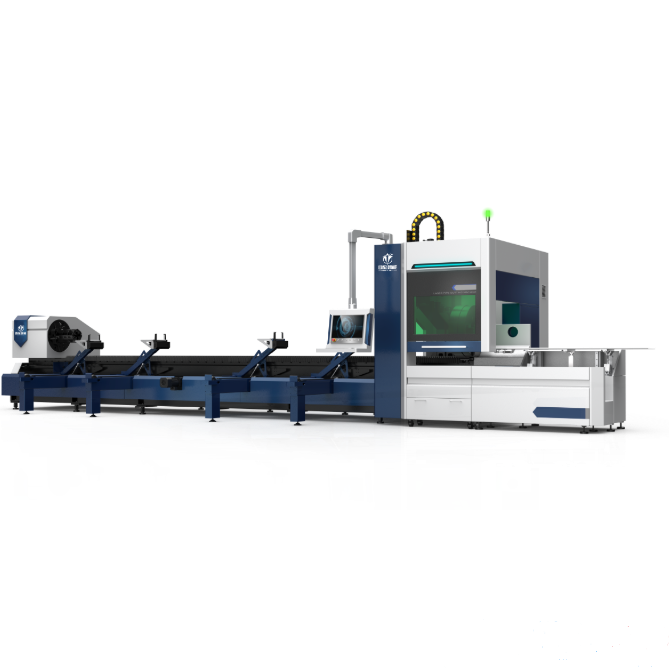

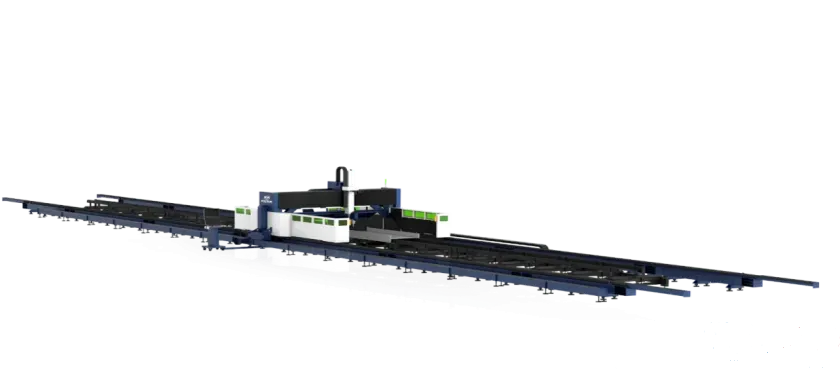

One machine for multiple uses, comprehensively solving processing problems

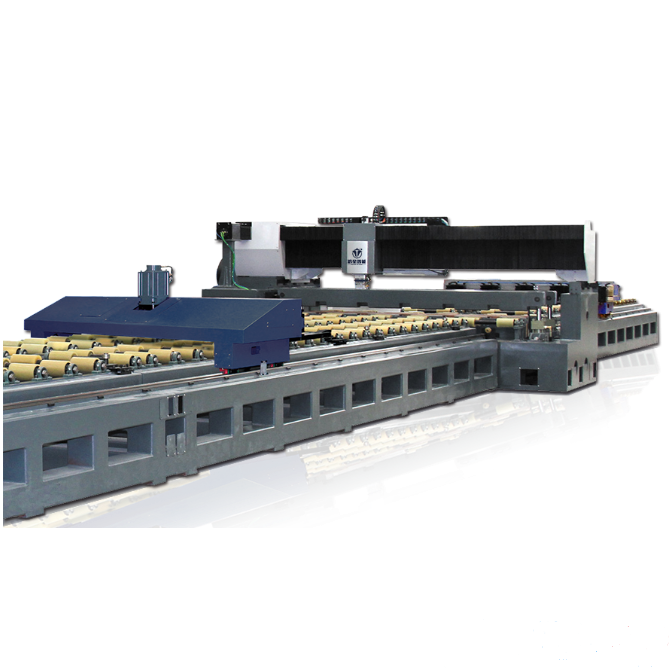

Multi functional integration: cutting, locking, chamfering, marking, one-stop completion, bidding farewell to tedious processes!

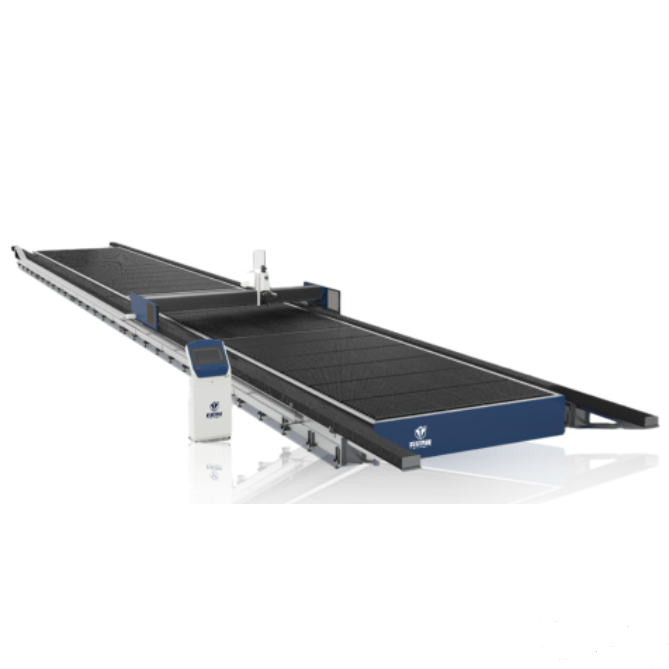

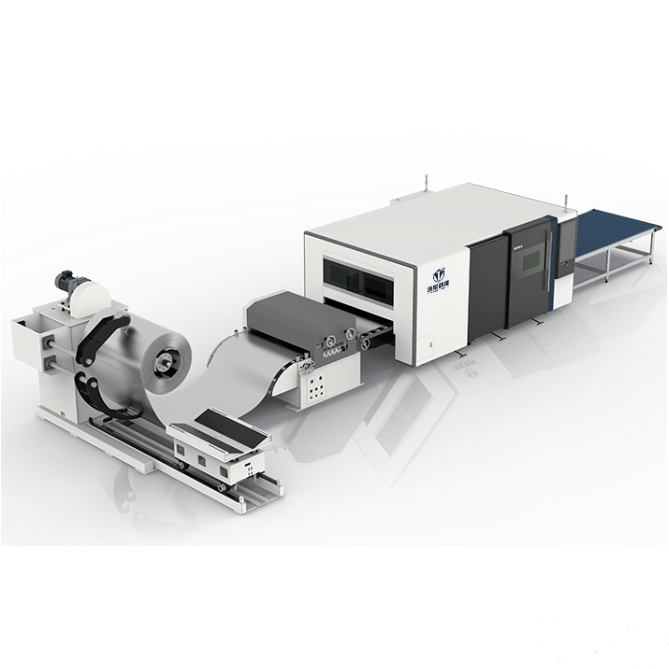

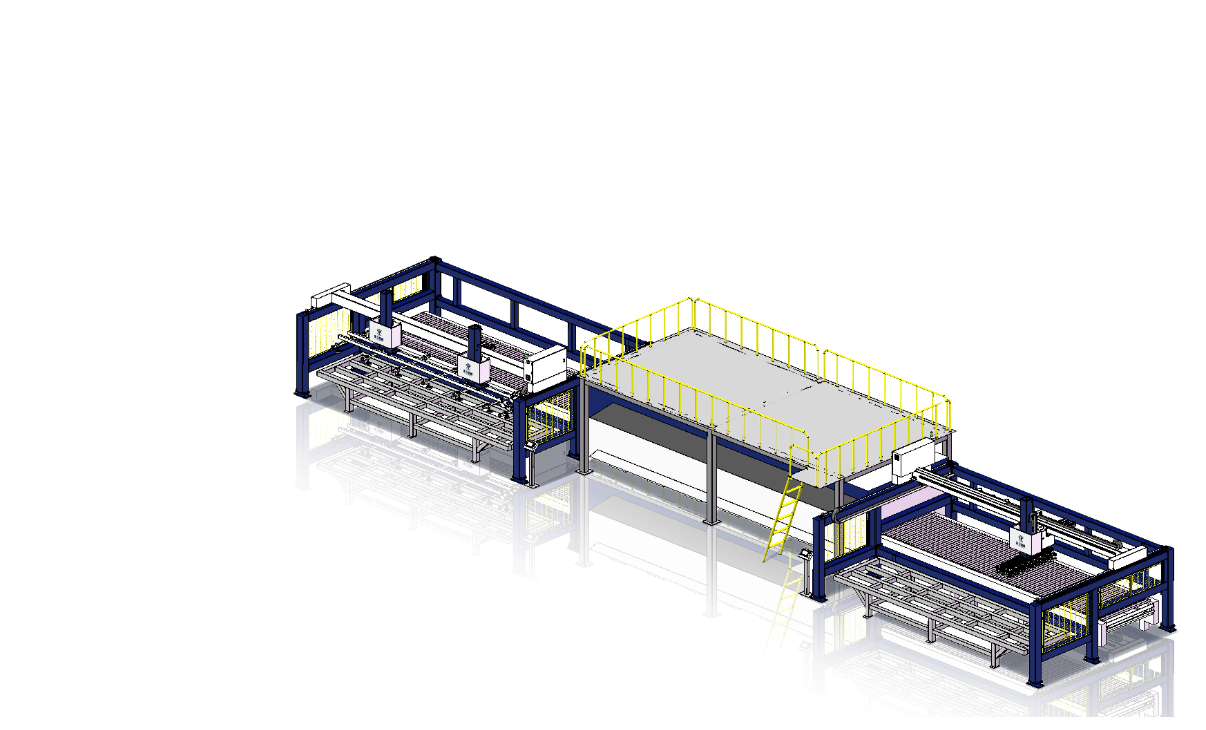

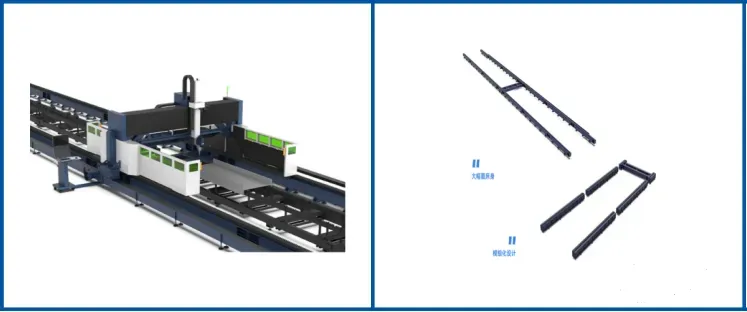

Flexible selection: Modular design, supporting single station (14 meters) and dual station (28 meters) to meet different production needs.

Efficient Replacement: One device can replace traditional manual processes such as marking, drilling, groove cutting, and polishing, increasing efficiency by 300%!

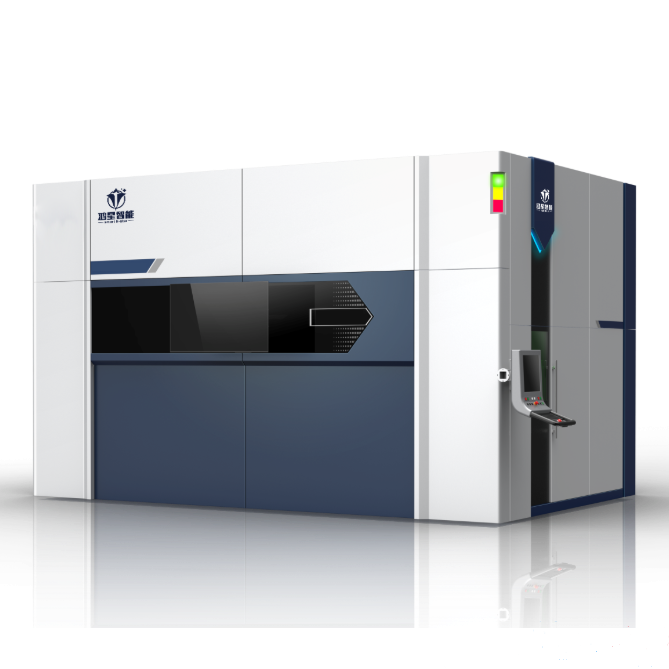

Core technology, precise and efficient

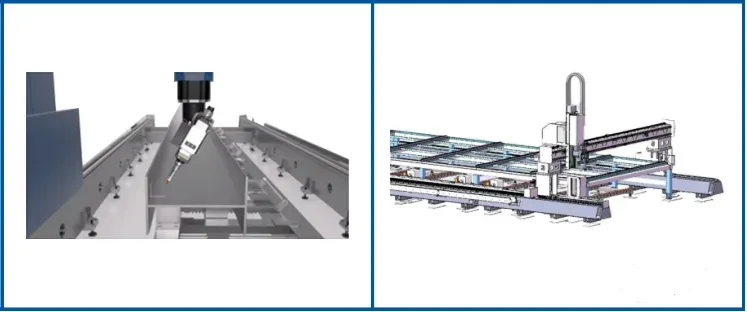

·Intelligent compensation: Real time measurement of steel dimensions, automatic correction of errors, avoiding cutting misalignment, continuous cutting, collision and other problems.

·Intelligent nesting: seamless integration with Tekla, efficient drawing and layout, optimized material utilization, and reduced waste rate.

·Special features: Supports switching between multiple varieties and specifications, can process irregular parts such as heads, and can also achieve flat straight groove cutting, with strong adaptability!

·Cantilever option: For small and medium-sized steel processing, a cantilever structure is adopted with one side open for more convenient operation.

Widely applicable scenarios, helping enterprises reduce costs and increase efficiency

Steel structure building: efficient processing of H-beams and plates, shortening the construction period

Heavy machinery: precise groove and locking cutting to improve welding quality

Shipbuilding: Processing of irregular parts to meet complex process requirements

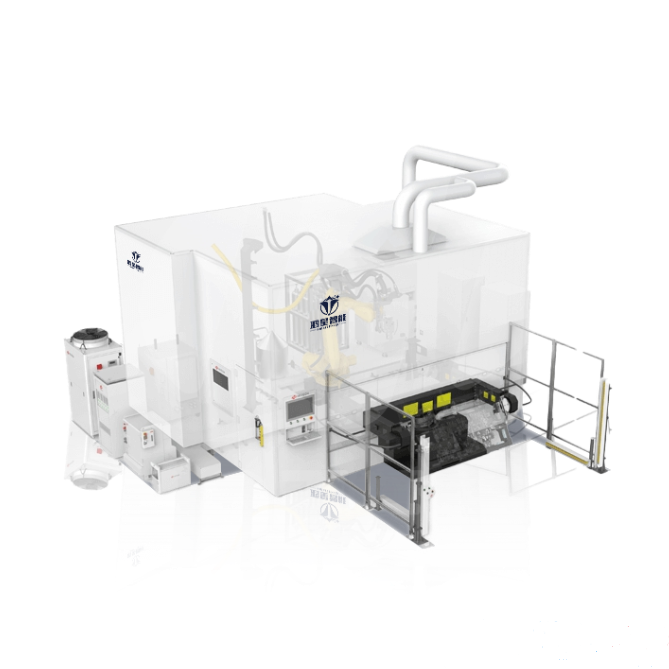

Automated production line: can be linked with assembly welding equipment to create an intelligent processing assembly line

Why choose our profile laser cutting machine?

✔ Labor saving: Reduce manual intervention and lower labor costs

✔ Time saving: Complete multiple processes at once, doubling production efficiency

✔ Material saving: Intelligent nesting to reduce waste

✔ High precision: laser cutting, error controlled at millimeter level

Empower production with technology and create value through efficiency!