[Successful Case] Perfect relocation of laser cutting machine & laser tube cutti

Release Date:2025/07/17

When relocating large precision equipment, the biggest fear is equipment damage and production delays! But this time, our professional team not only helped the customer move the equipment without damage, but also discovered and solved potential equipment problems during the relocation process, making the equipment run more smoothly than before!

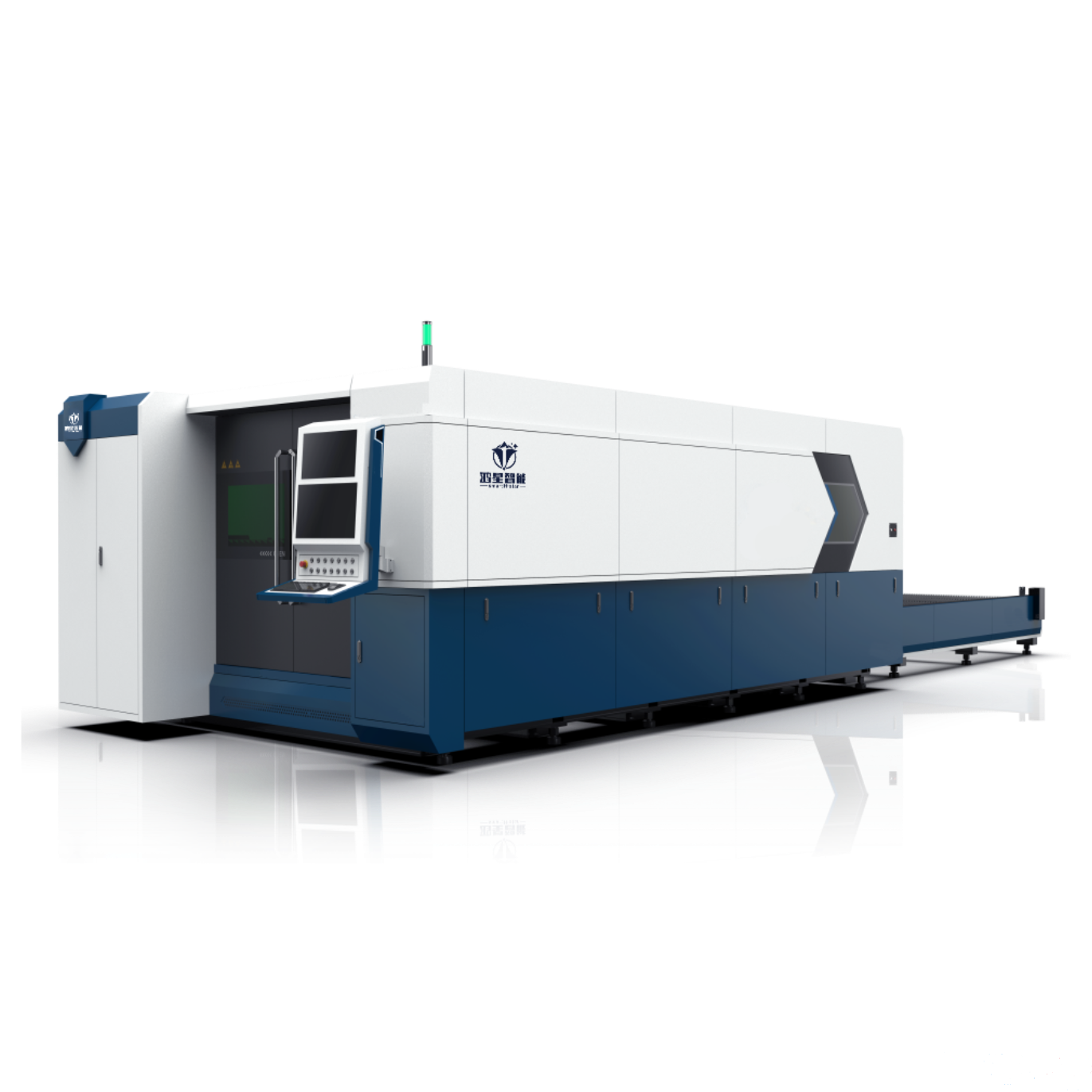

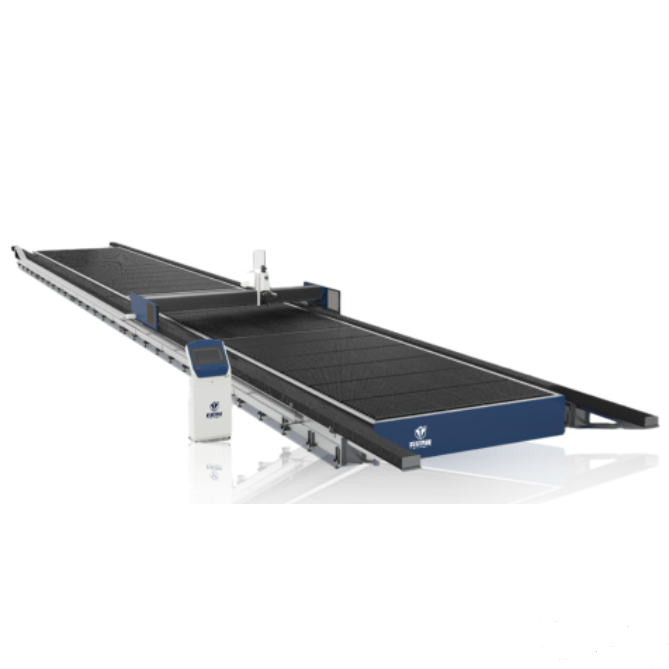

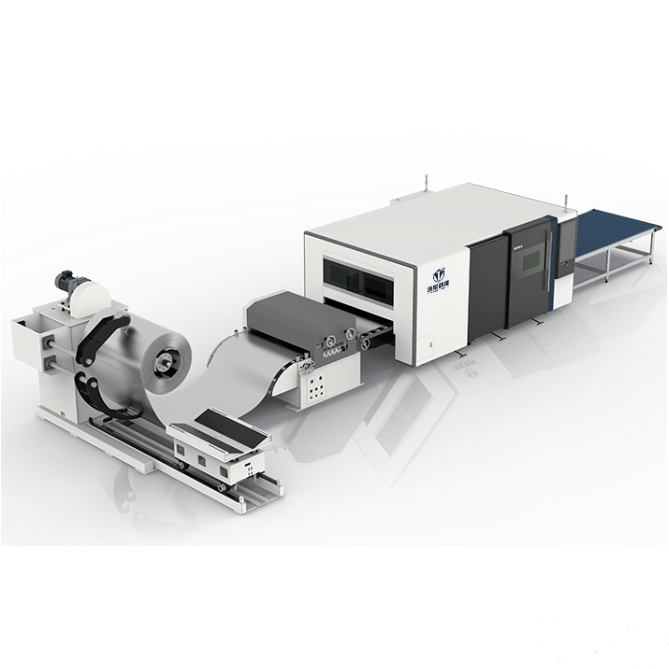

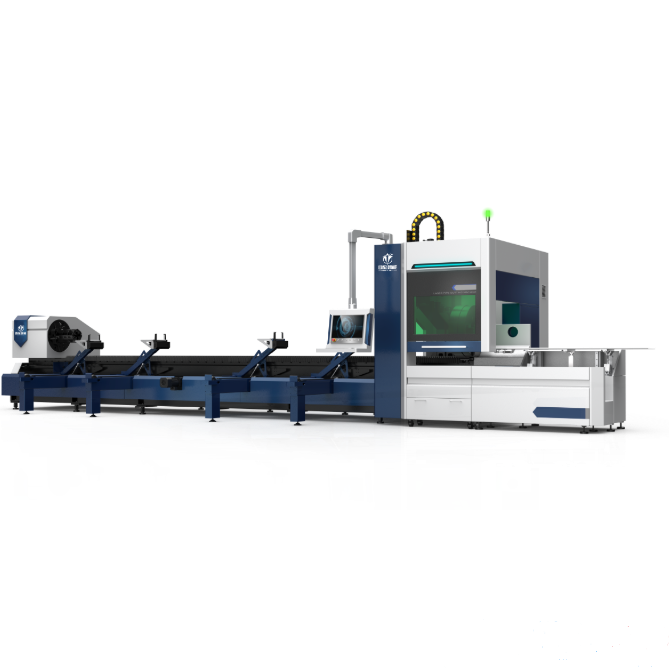

Customer pain point: How to ensure zero risk when relocating laser cutting machines and laser tube cutting machines?

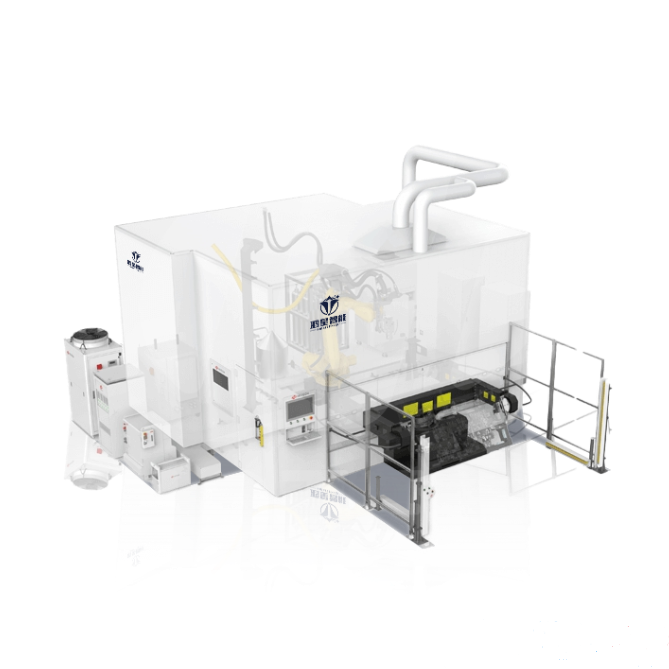

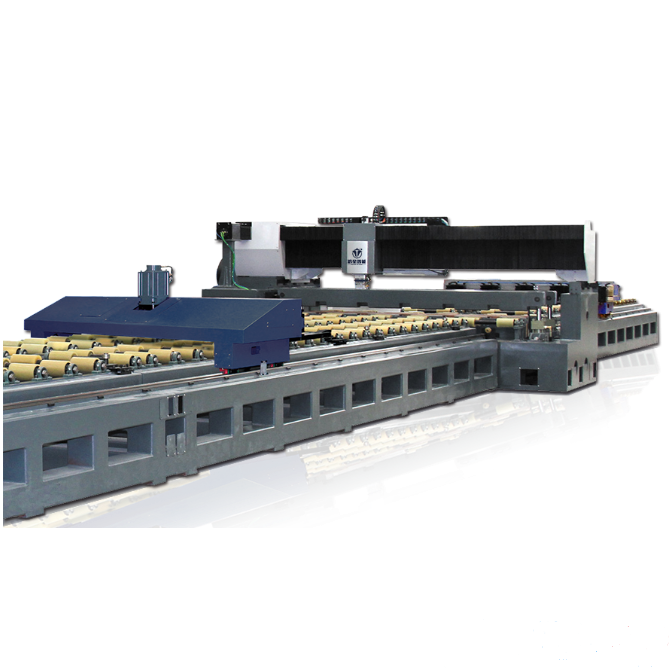

The laser cutting machines and laser tube cutting machines in the customer's factory need to be relocated to a new location, but the equipment structure is complex and the precision requirements are extremely high. A little carelessness may cause:

✅ Optical component offset, affecting cutting accuracy

✅ Mechanical structure deformation, reducing equipment life

✅ Electrical system failure, causing downtime risk

What customers are most worried about is that the equipment performance will decline after the relocation, delaying production!

Our solution: Professional engineers escort the whole process

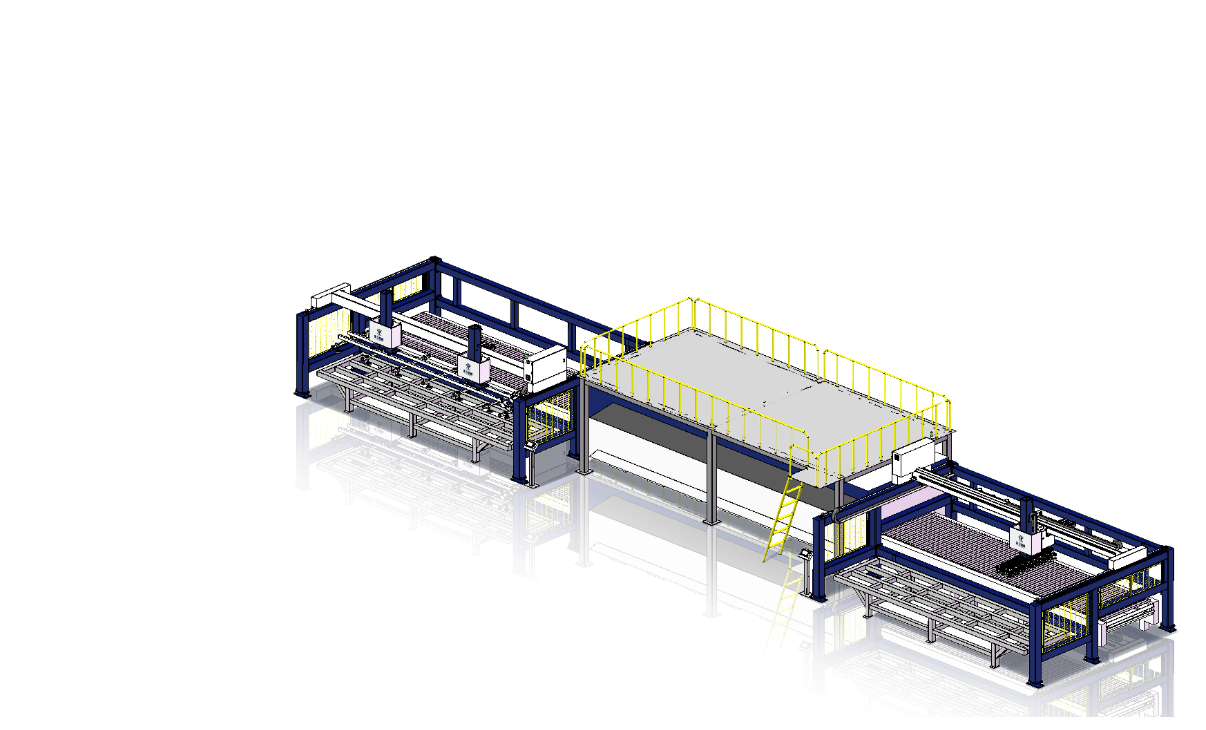

1️, customized relocation plan:

Engineers evaluate the equipment status on site and formulate step-by-step disassembly, transportation and installation plans

Use shockproof packaging + precision instrument calibration to ensure zero damage to optical and mechanical components

2️, hidden problems found during relocation will be solved together!

During the machine relocation process, engineers found that the guide rails of the laser cutting machine were slightly worn, and long-term use may affect the accuracy. Impurities accumulated in the cooling system of the pipe cutting machine may cause overheating failure. The electrical circuit was partially aged, and there was a risk of short circuit. → We repaired and optimized on the spot to avoid subsequent production risks!

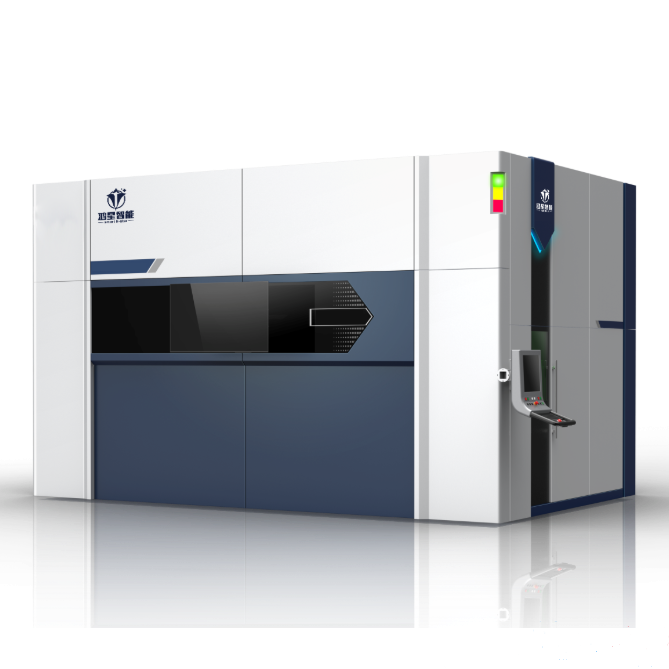

3️、Fully debugged after installation, better performance

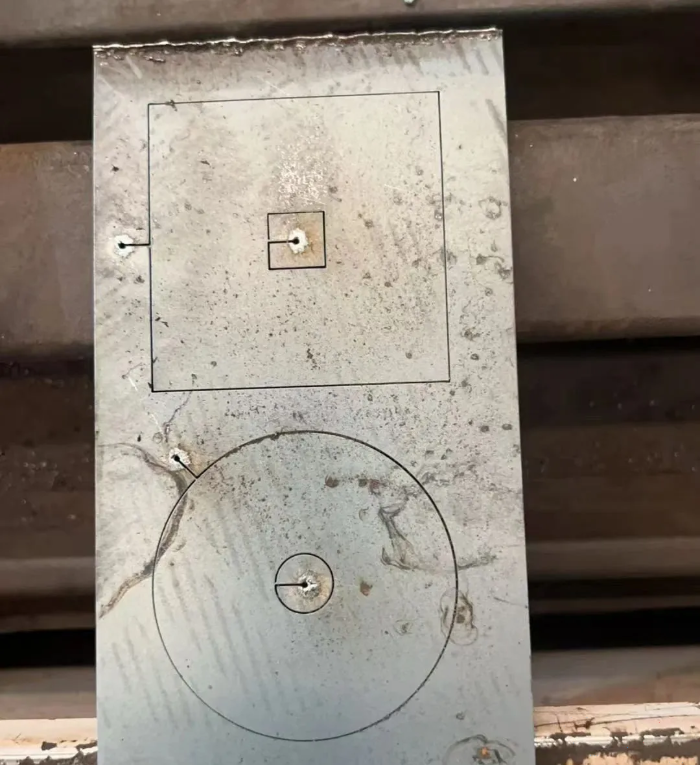

Recalibrated the laser optical path, cutting accuracy is higher than before relocation

Optimized equipment parameters, operating efficiency increased by 10%+

Surprising feedback from customers: "The equipment is more useful than before!

Why choose us for machine relocation?

✨Non-destructive relocation: professional disassembly and assembly + customized solutions, 100% guarantee of equipment safety

✨Problem pre-inspection: troubleshoot hidden dangers during the relocation process to avoid subsequent losses

✨Efficiency first: from disassembly to debugging, the whole process is efficient and does not delay production

Customer evaluation

"I was worried that the machine moving would affect the accuracy of the equipment, but I didn't expect that not only did it not cause any problems, but it also helped us optimize performance! It's worth it!"

——Production manager of the customer company