Laser Handheld Welding Applications and Benefits

Release Date:2025/03/28

introduction

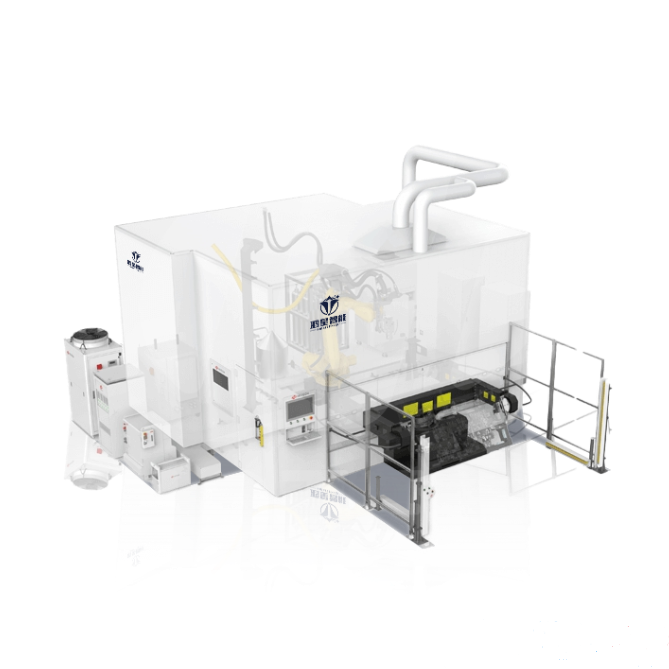

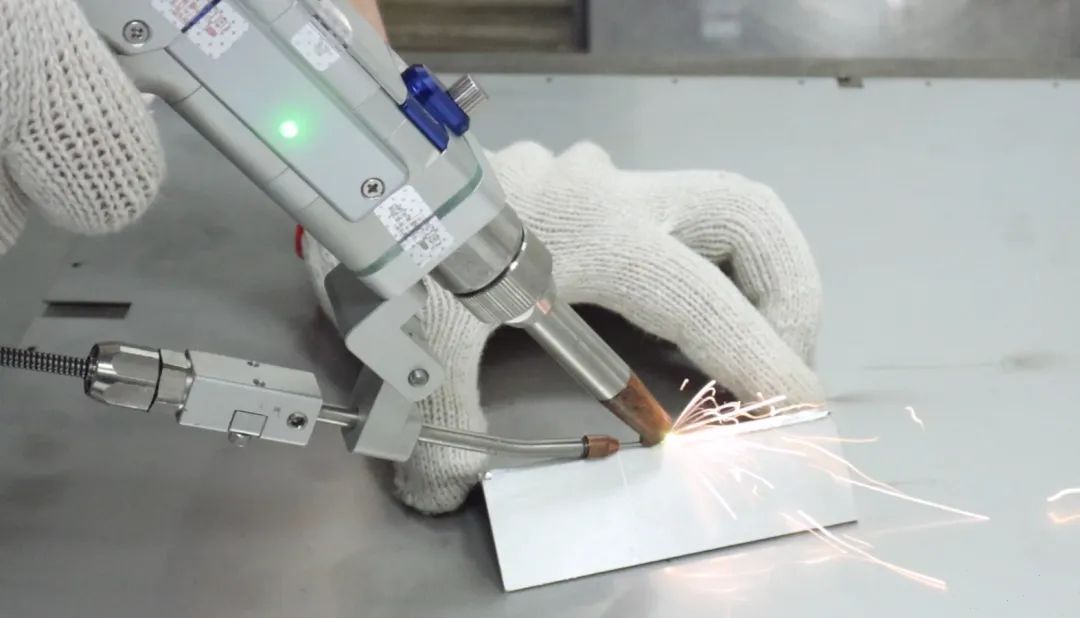

Handheld fiber laser welding machine is a new generation of laser welding equipment, belongs to the non-contact welding, the operation process does not need to be pressurized, its working principle is the high energy intensity of the laser beam directly irradiated on the surface of the material, through the interaction between the laser and the material, so that the material melts internally, and then cooled and crystallized to form a weld.

Handheld welding is a portable operating device. It is also a precision welding machine, but can be used freely and flexibly in a variety of environmental applications. It can be easily applied in all types of environments with higher professional standards and reliability. Handheld welding machines have the advantage of high standards and specialization in the production of professional targets.

At the same time, it is a practical and user-friendly design that ensures accurate welding targets. At the same time, it improves the welding defects in the traditional welding process, such as biting edge, incomplete depth of fusion, dense porosity and cracks. Handheld fiber laser welding machine seam smooth and beautiful, reducing the subsequent grinding process, saving time and time. High cost, less consumables, long service life are well received by the market.

Advantages of Handheld Laser Welding

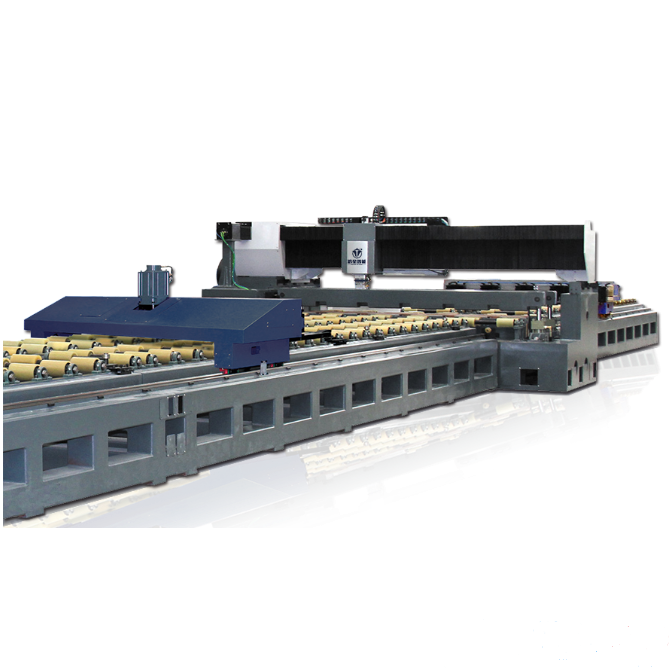

1. Wide welding range: handheld welding head is equipped with 5m-10m original fiber optic, to overcome the limitations of the workbench space, outdoor welding, long-distance welding;

2. easy to use and flexible: handheld laser welding is equipped with mobile pulleys, comfortable grip, adjust the workstation at any time, without the need for fixed-point workstation, free and flexible, suitable for a variety of work environment scenarios.

3. a variety of welding methods: can realize the welding of any angle, stack welding, butt welding, vertical welding, flat angle welding, internal angle welding, external angle welding, etc., can be a variety of complex weldments of the workpiece, the larger workpiece non-regular shape welding, and realize the welding of any angle. In addition, it can also complete the cutting, welding and cutting free switching, only need to change the welding nozzle for cutting nozzle, very convenient.

|

|

|

splice welding | overlay soldering | T-welding |

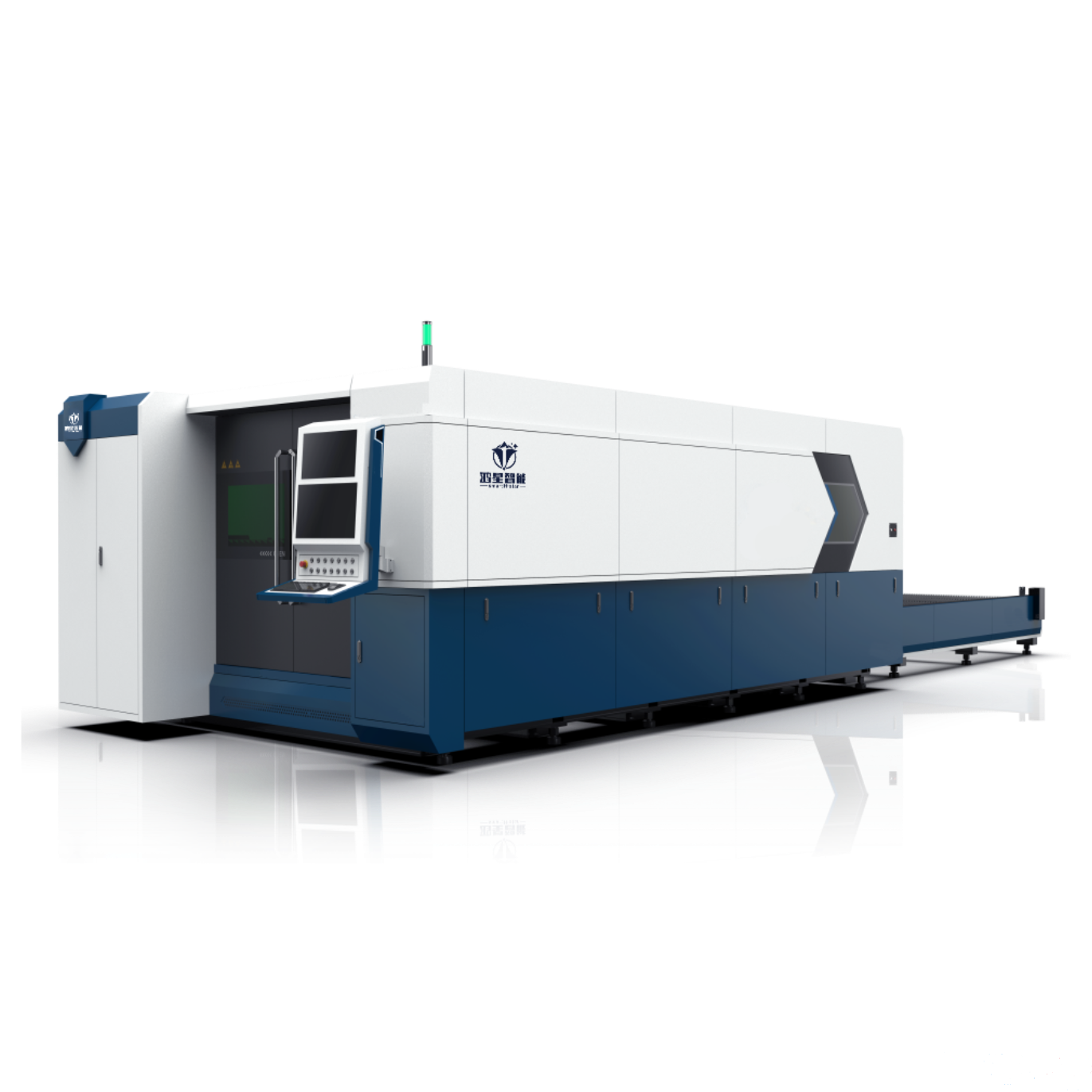

4. Welding effect is good: handheld laser welding is thermal welding, compared with traditional welding, laser welding has a higher energy density, can achieve better welding effect, welding area heat effect is small, not easy to deformation, blackening, back traces of the problem, the welding depth is large, melting sufficiently, firmly and reliably, the weld strength reaches or even exceeds the base material itself, which is the ordinary welding machine can not be guaranteed.

Beautiful weld seam, no deformation of workpiece

5. Simple to operate and easy to achieve high-quality welding results

6. Suitable for small-scale production: compared with the deployment of fully automated equipment, handheld laser welding machine has a lower production compliance rate. But for small-scale processing or non-large-scale welding production workshop, manual laser welding is a better choice, without the need to set up equipment to deploy the welding table, occupies a small space, for the welding of product diversification, product shape flexibility, laser handheld welding machine can fully meet the needs of this production.

7. Low maintenance costs: handheld laser welding without the need to add wire, basically no consumable costs. Pump source life of up to 100,000 hours or more, daily maintenance-free, labor-saving more worry.

Comparison of Handheld Laser Welding Machine and Tig Welding

1. Comparison of energy consumption:

Compared with the traditional arc welding, handheld laser welding machine saves about 80%-90% of electric energy, processing costs can be reduced by about 30%.

2. Welding effect comparison:

Laser handheld welding can complete dissimilar steel and dissimilar metal welding. Fast speed, small deformation, small heat affected zone. Weld seam is beautiful, flat, no/few porosity, no pollution. Handheld laser welding machine can perform tiny open parts and precision welding.

3. Comparison of follow-up process

Laser handheld welding with low heat input, workpiece deformation is small, you can get a beautiful welded surface, no need or only need to be briefly processed (depending on the welding surface effect requirements). Handheld laser welding machines can greatly reduce the labor cost of the huge polishing and leveling process.

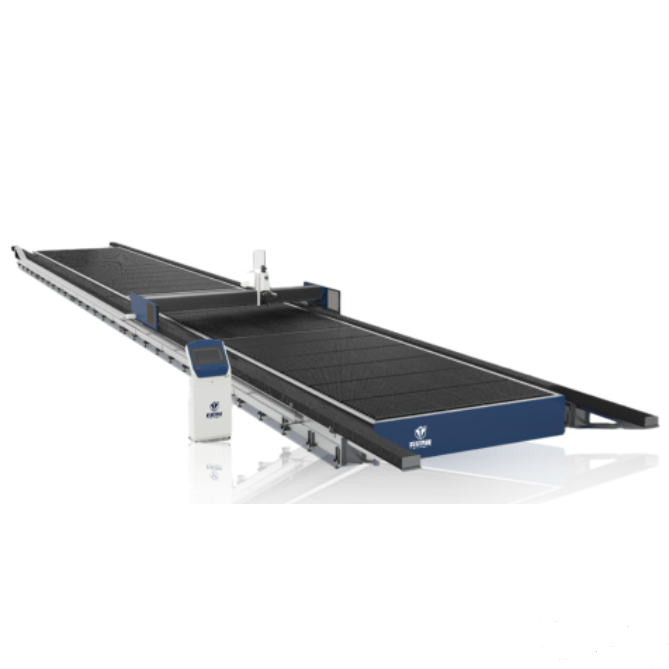

Handheld Laser Welding Application Areas

Handheld laser welding can be widely used in cabinet kitchen and bathroom, stairs and elevators, shelves, ovens, stainless steel doors and windows guardrail, distribution box, stainless steel home and other industries complex irregular welding process. Also widely used in kitchens, household appliances, advertising, molds, stainless steel doors and windows, handicrafts, home furnishings, furniture, auto parts and many other industries.