What materials can laser welding weld?

Release Date:2024/10/15

Laser welding technology, due to its high energy density, high precision, and wide range of applications, can weld a variety of materials. Specifically, the materials that laser welding can weld mainly include the following categories:

1、 Metal materials

Conventional metal materials:

stainless steel: Stainless steel is one of the commonly used materials in laser welding, widely used in the manufacturing of automotive parts, machine equipment parts, household appliances, etc.

aluminium alloy: Aluminum alloy and its aluminum copper joints are common materials in laser welding, especially widely used in industries such as aerospace, automotive, electronic equipment, and home appliances. Laser welding of aluminum alloys can result in welding structures with extremely high strength, no porosity, and no risk of cracking.

Copper and copper alloys:Copper and its alloys have high conductivity, thermal conductivity, and strength. Laser welding can quickly and efficiently weld copper materials and can be used to manufacture complex structural parts and electronic components.

Magnesium alloy: Laser welding technology can weld and connect various magnesium alloys, improve their corrosion resistance, and is widely used in fields such as marine engineering.

Carbon steel and alloy steel:Various types of carbon steel and alloy steel, such as mold steel, can be connected through laser welding technology。

other non-ferrous metals:Various metals and alloys such as titanium, nickel, tin, chromium, niobium, gold, silver, etc. exhibit different welding characteristics in laser welding.

dissimilar metal:Laser welding technology can also achieve welding between dissimilar metals, such as copper nickel, nickel titanium, copper titanium, titanium molybdenum, brass copper, low-carbon steel copper, and other combinations, greatly enhancing the flexibility of product design.

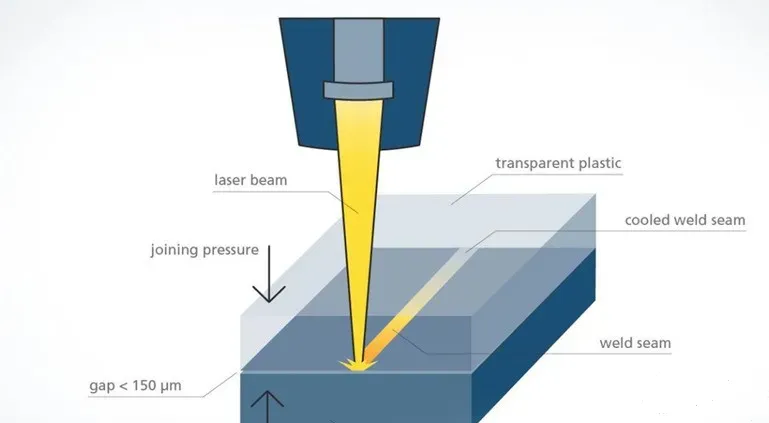

2、 Plastic materials

Laser welding is also widely used in plastic materials, especially for welding thermoplastic materials. These plastic materials include but are not limited to:

Polyvinyl chloride (PVC)

Polypropylene (PP)

Polystyrene (PS)

Fluororesin (PFA)

Olefin resin (PE)

Engineering resins (PBT, PA6, PC, POM)

Super engineering resins (PSF, PPS, PEEK, PEI, LCP)

When laser welding plastics, by selecting the appropriate laser wavelength and power, the heat input can be controlled to achieve fast and stable welding, which is widely used in industries such as electronic products, medical devices, automotive manufacturing, and 3C digital.

3、 Other materials

In addition to metals and plastics, laser welding can also be performed on the following materials:

ceramics:Some types of ceramic materials can also be connected through laser welding.

quartz:Laser welding technology is also applied in the processing of quartz materials.

Carbon fiber composite material:Laser welding can weld carbon fiber composite materials and maintain their excellent performance.

glass:Although it is traditionally believed that transparent materials such as glass are not suitable for laser welding, modern technology has been able to perform laser welding on glass under certain conditions, especially in fields such as glassware manufacturing and optical instrument manufacturing.

electronic component:Laser welding technology can also be used for welding electronic components such as circuit boards, chips, sensors, etc.

summarize

Laser welding technology, due to its unique advantages, can weld a variety of materials, including metals, plastics, ceramics, quartz, carbon fiber composite materials, as well as some glass and electronic components. In practical applications, it is necessary to select appropriate laser welding parameters and processes based on the characteristics and requirements of specific materials to achieve the best welding effect.