Hongxing intelligent unveils the application of all kinds of lasers in laser cle

Release Date:2024/08/08

The essence of laser cleaning is to irradiate the laser beam with high energy density to the surface of the workpiece, so that the dirt, oxide layer, coating or coating on the surface of the workpiece is heated and instantaneous melting, ablation, evaporation or stripping, so as to achieve the surface cleaning of the workpiece without damaging the substrate process, is the ideal choice for a new generation of industrial cleaning technology!

In 1960, American scientist Theodore Harold Mayman successfully developed the world's first practical ruby laser, which opened the door for the benefit of mankind. Over the next 60 years, the application field of laser technology has gradually expanded, and important results have been achieved in the application of welding, cleaning, cutting, marking and other fields.

Laser type suitable material

Foreign laser cleaning concept originated earlier, from the thick rust layer to the surface of the fine particles can be removed. Since the 21st century, China has invested a lot of manpower and material resources to strengthen the research of laser cleaning technology, with the development of advanced laser technology, laser whether in the energy output, wavelength range or in the laser quality, energy efficiency have achieved a leap forward development.

Laser development also promotes the rapid development of laser cleaning technology in China, laser cleaning technology has also become an indispensable cleaning technology in high-end manufacturing fields such as industry, shipbuilding, aerospace, etc., including the removal of rubber dirt on the surface of tire molds, the removal of silicone oil pollutants on the surface of gold film, and the high-precision cleaning of the microelectronics industry.

Rust removal, paint removal, oil removal and oxidation removal of metal surfaces are the most widely used areas of laser cleaning. Due to the differences between different lasers in important parameters such as wavelength and power, different materials and stains have different requirements for laser wavelength and power, and different laser cleaning methods need to be selected according to the actual situation in the actual cleaning work.

After a large number of experiments by Hongxing intelligent process research and development team, MOPA laser and composite laser are the most widely used lasers in the laser cleaning market, followed by a small number of carbon dioxide lasers, ultraviolet lasers, continuous lasers.

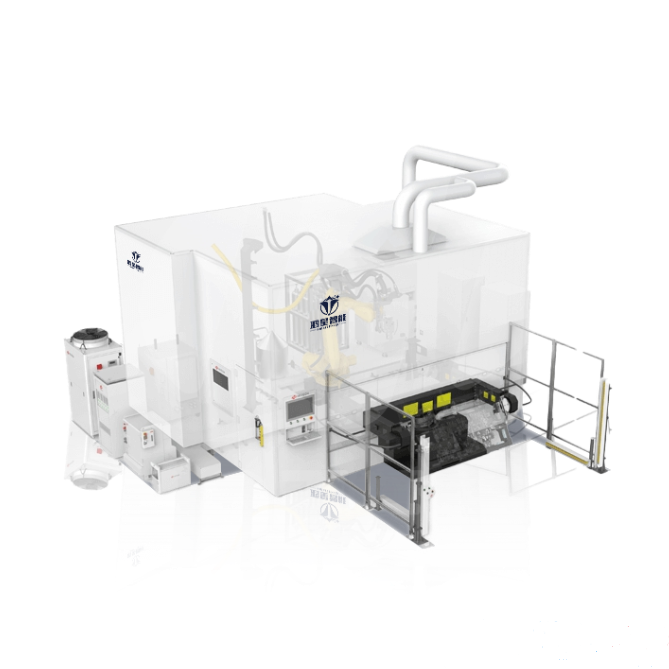

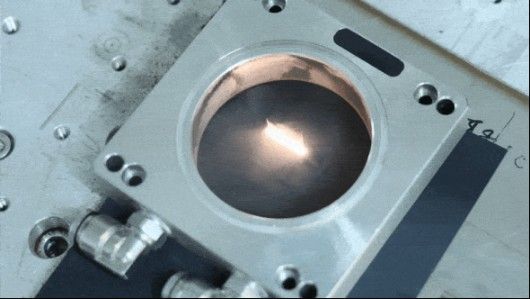

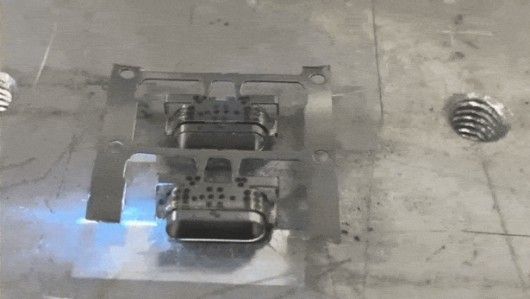

MOPA pulsed laser cleaning

Meet all kinds of material surface cleaning

The resonator of the MOPA fiber laser system is itself an optical fiber. The MO (Master Oscillator) is a low-power laser, usually with a suitable wavelength. Low Power laser Diode (LD) can directly modulate the output parameters through the drive current, and then coupling the signal optical generated by the LD into the Power Amplifier (PA) power amplifier system through the pigtail for signal optical amplification.

MOPA laser is one of the most widely used laser cleaning, because the MOPA fiber laser system can be amplified strictly according to the seed signal source coupled into the system, without changing the relevant characteristics of the laser such as the center wavelength, pulse waveform and pulse width. Therefore, the parameter adjustment dimension is higher, the range is wider, for different application scenarios of different materials, the adaptability is stronger, the process window interval is larger, and the surface cleaning of various materials is met.

In addition, the MOPA laser has a high laser energy margin, and the laser cleaning equipment can be upgraded by improving the laser cleaning device, such as increasing the laser processing spot and cooperating with the intelligent system. It is worth mentioning that due to the excellent performance and flexible scenario applicability of the MOPA laser, it is especially widely used in emerging industries such as new energy batteries.

New energy power battery | Lithium battery electrode plate cleaning, pole cleaning, liquid injection port cleaning, cover plate cleaning, blue film cleaning, etc. |

aerospace | Engine parts before and after welding cleaning; Cleaning the carrier rocket storage box before and after welding; Paint removal and release agent removal for composite materials; Aircraft skin removal; Sealant removal; Mold cleaning; |

Mold product | Tire mold, packaging mold, injection mold, sealing ring mold, food mold and other carbon layer removal; |

3C industry | Circuit board selection paint removal, wafer cleaning, phone case paint removal, PVD coating fixture cleaning; |

Automobile manufacturing | Body cleaning before welding, wheel hub cleaning, body selection paint removal, silent tire cleaning; |

Ocean ship | Ocean ship |

Bridge, highway maintenance | Paint and rust removal of bridge structural parts; Highway guardrail paint removal; |

rail traffic | Aluminum alloy body before and after welding cleaning; Automatic wheelset cleaning, bogie cleaning, motor cleaning, etc. |

Petrochemical industry | Offshore platform coating removal; Pipe paint removal, rust removal, etc.; |

Food industry | Soy sauce fermenter, metal baking tray, mold, etc.; |

Vacuum cup | Insulation cup bottom, cup wall to remove paint; |

Other industries | Metal oil filter, filter tube cleaning; Stainless steel polishing; Laser rust removal, oxide removal; |

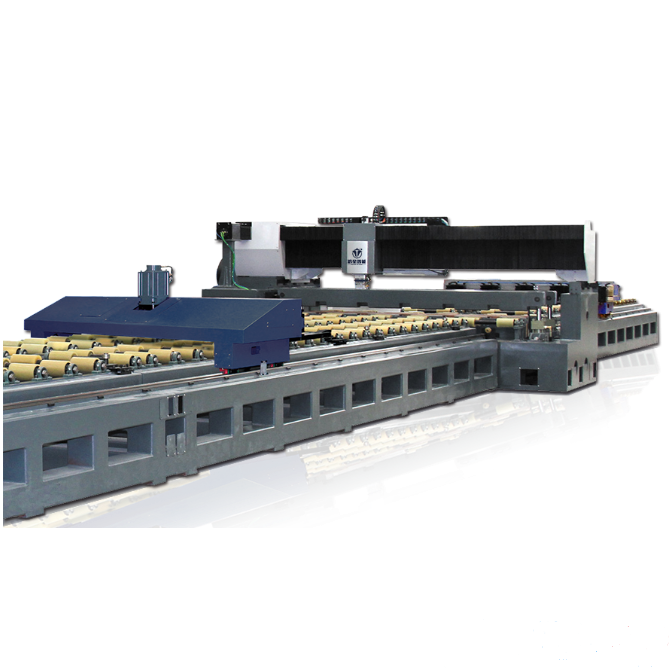

Composite laser cleaning

The best choice for paint removal

Laser composite cleaning through the semiconductor continuous laser as a heat conduction output, so that the adhesion to be cleaned to absorb energy to produce gasification, plasma cloud, and the formation of thermal expansion pressure between the metal material and the adhesion, reduce the bonding force between the two layers. When the laser output high-energy pulsed laser beam, the generated vibration shock wave makes the adhesion force is not strong directly out of the metal surface, so as to achieve rapid laser cleaning.

Remove paint from power battery housing

Laser composite cleaning simultaneously combines continuous laser and pulsed laser functionally, forming 1+1 > 2 processing characteristics. Fast speed, high efficiency, more uniform cleaning quality, for different materials, can also use different wavelengths of laser cleaning at the same time to achieve the purpose of removing stains.

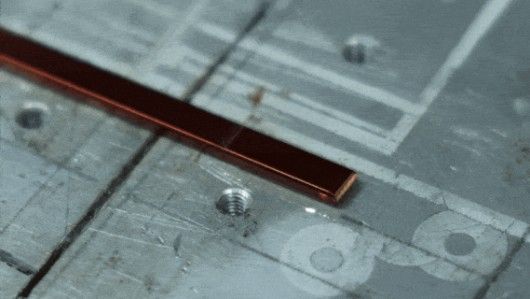

Hairpin motor paint removal

At present, laser composite cleaning is widely used in ship, auto repair, rubber mold, high-end machine tools, track and environmental protection and other fields, effectively remove the surface of the object resin, paint, oil, stains, dirt, rust, coating, coating and oxide layer.

For example, in the laser cleaning of thicker coating materials, the single laser multi-pulse energy output is large and the cost is high, and the pulsed laser-semiconductor laser composite cleaning can quickly and effectively improve the cleaning quality without causing damage to the substrate; In the laser cleaning of aluminum alloy and other highly reflective materials, a single laser has problems such as large reflectivity, the use of pulsed laser - semiconductor laser composite cleaning, under the action of semiconductor laser thermal conductivity transmission, increase the energy absorption rate of the oxide layer on the metal surface, so that the pulsed laser beam can peel the oxide layer faster, so as to more effectively improve the removal efficiency, especially the paint removal efficiency increased by more than 2 times.

Co2 laser cleaning

Clear non-metallic materials of choice

Carbon dioxide laser is a gas laser with CO2 gas as the working substance, which is filled with CO2 gas and other auxiliary gases (helium and nitrogen and a small amount of hydrogen or xenon), with good directivity, monochromity and frequency stability. Because discharge tubes are usually made of glass or quartz materials, common CO2 lasers are glass tube CO2 lasers and metal RF tube CO2 lasers.

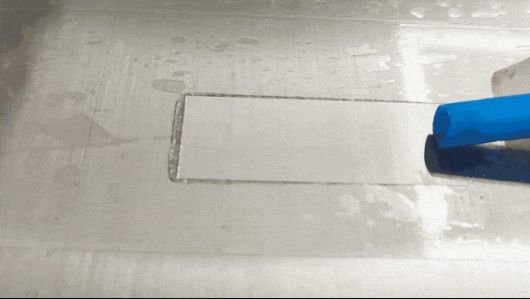

Gel removal

Based on its unique wavelength, CO2 lasers are the best choice for surface cleaning of non-metallic materials such as glue removal, coating removal and ink removal. For example, a CO2 laser is used to remove the composite paint layer on the surface of an aluminum alloy without damaging the surface of the anodic oxide film or reducing its thickness. Hongxing Intelligent has a wealth of laser cleaning solutions in the 3C industry PCB ink cleaning, new energy power battery pole sheet roll rubber cleaning, soft pack pole ear sealing, and can provide customized needs for customers.

Soft cover pole ear seal to remove glue

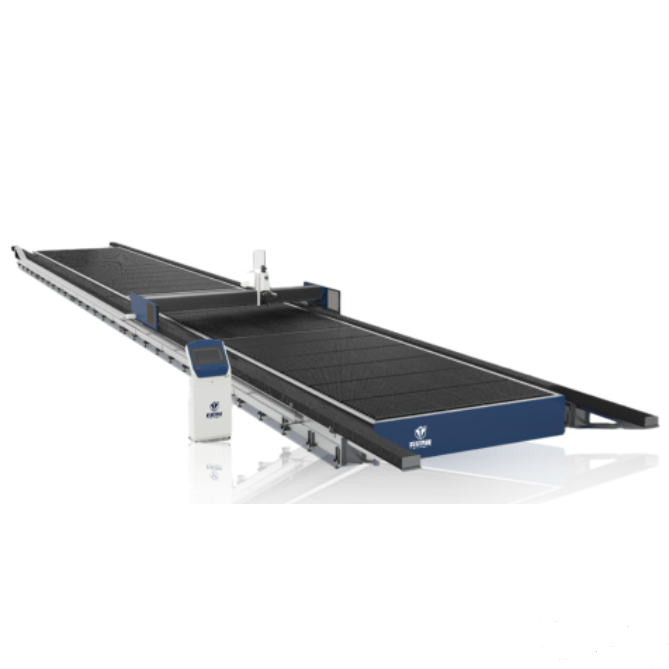

Uv laser cleaning

Apply precision component

The main ultraviolet lasers used for laser microfabrication are excimer lasers and all-solid-state lasers. Ultraviolet laser wavelength is short, single photon energy is high, can directly break the chemical bond between materials, materials in the form of gas or particles are stripped off the surface, the heat affected zone generated during processing is small, in the micro manufacturing has a unique advantage, such as Si, GaN and other semiconductor materials, quartz, sapphire and other optical crystals, And polyimide (PI), polycarbonate (PC) and other polymer materials, can effectively improve the manufacturing quality.

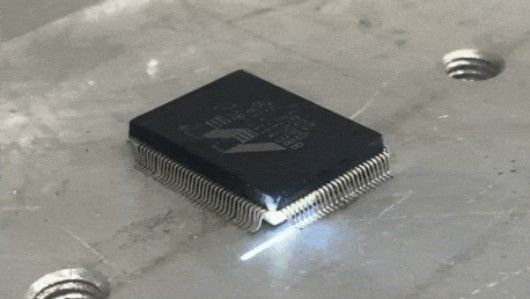

Chip pin cleaning

Ultraviolet laser is considered to be the best laser cleaning solution in the field of precision electronics, and its most characteristic fine "cold" processing technology does not change the physical properties of the object at the same time, micro-machining and treatment of the surface, can be widely used in communications, optics, military, criminal investigation, medical and other industries and fields. For example, the 5G era has spawned FPC processing market demand. The application of ultraviolet laser machines makes it possible to precision cold machining of materials such as FPC.

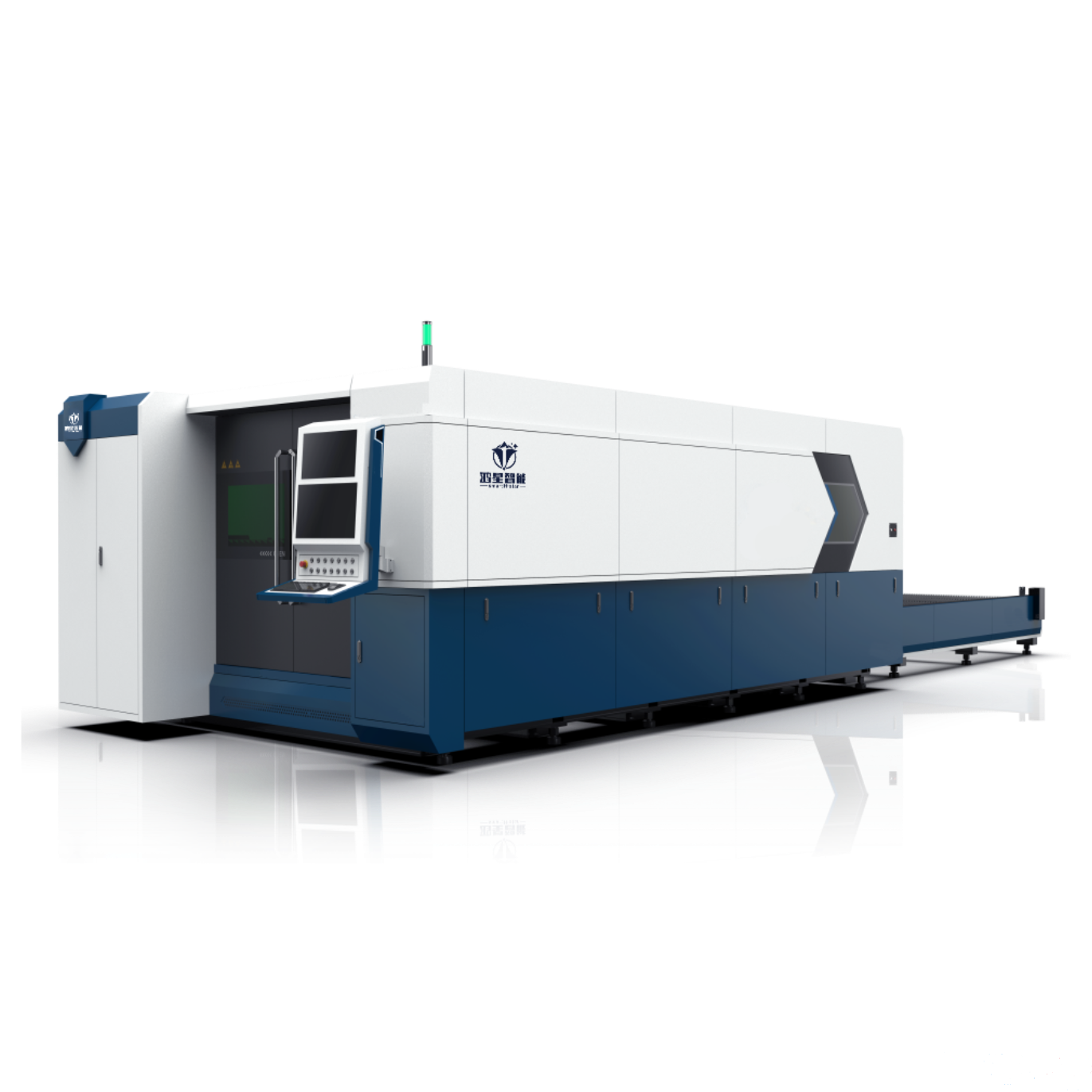

Continuous fiber laser cleaning

Remove rust from metal surface

The working principle of continuous fiber laser is that the pump light emitted by the pump source is coupled into the gain medium through a mirror. Since the gain medium is the rare-earth element doped fiber, the pump light is absorbed, and the rare earth ions that absorb the photon energy undergo energy level transition and realize particle population reversal. The reversed particles pass through the resonant cavity and transition from the excited state back to the ground state to release energy. And form a stable laser output, the biggest advantage is that the light can be continuous.

Post-welding cleaning

In actual laser cleaning applications, continuous fiber lasers are used less, but there are also a small number of applications, such as some large steel structures, pipelines, etc., because of the large volume and fast heat dissipation, the substrate damage requirements are not high, you can choose continuous lasers.

Rust removal

It is worth mentioning that with the breakthrough and stability of the ring spot technology, the ring fiber laser with the advantages of convenient process adjustment and simple operation has been widely popularized in the field of welding and cleaning, and a large number of experiments by Hongxing intelligent process Center engineers have proved that the technology is used to remove floating rust and can greatly improve the cleaning efficiency.

With the progress of science and technology and the improvement of environmental protection requirements, laser cleaning will be more deeply and comprehensively involved in the iterative process of China's manufacturing industry, and become the main cleaning method of cleaner production in the industry. Hongxing Intelligent uphold the concept of joint win-win, intelligent future, for all walks of life welding, cleaning needs, has a wealth of laser equipment solutions!