Sheet metal parts related processing technology and cost accounting sharing

Release Date:2024/07/30

[1] Introduction

According to the basic processing methods of sheet metal parts, the following materials, bending, stretching, forming, welding, surface treatment. This describes the process requirements that should be paid attention to for each processing method.

[2] Cut the material

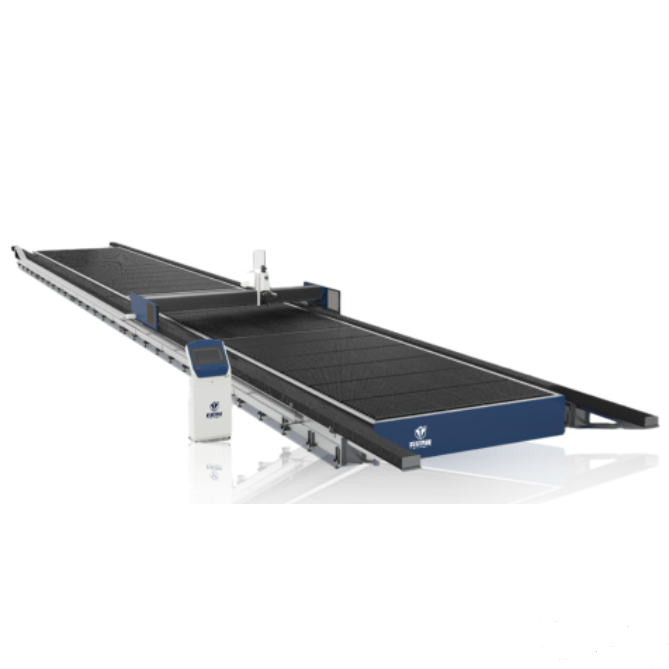

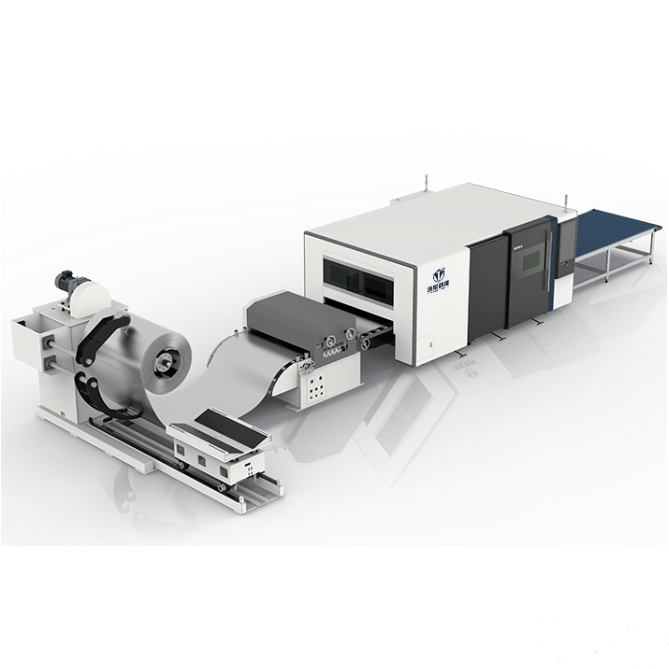

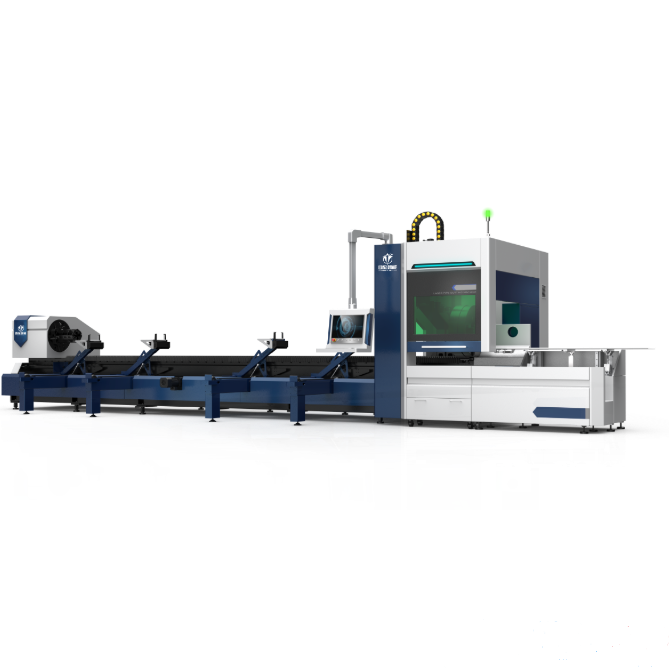

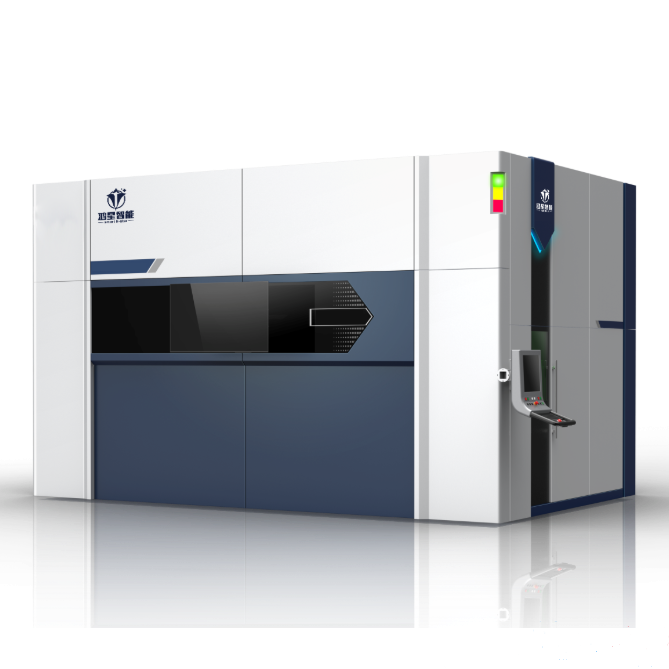

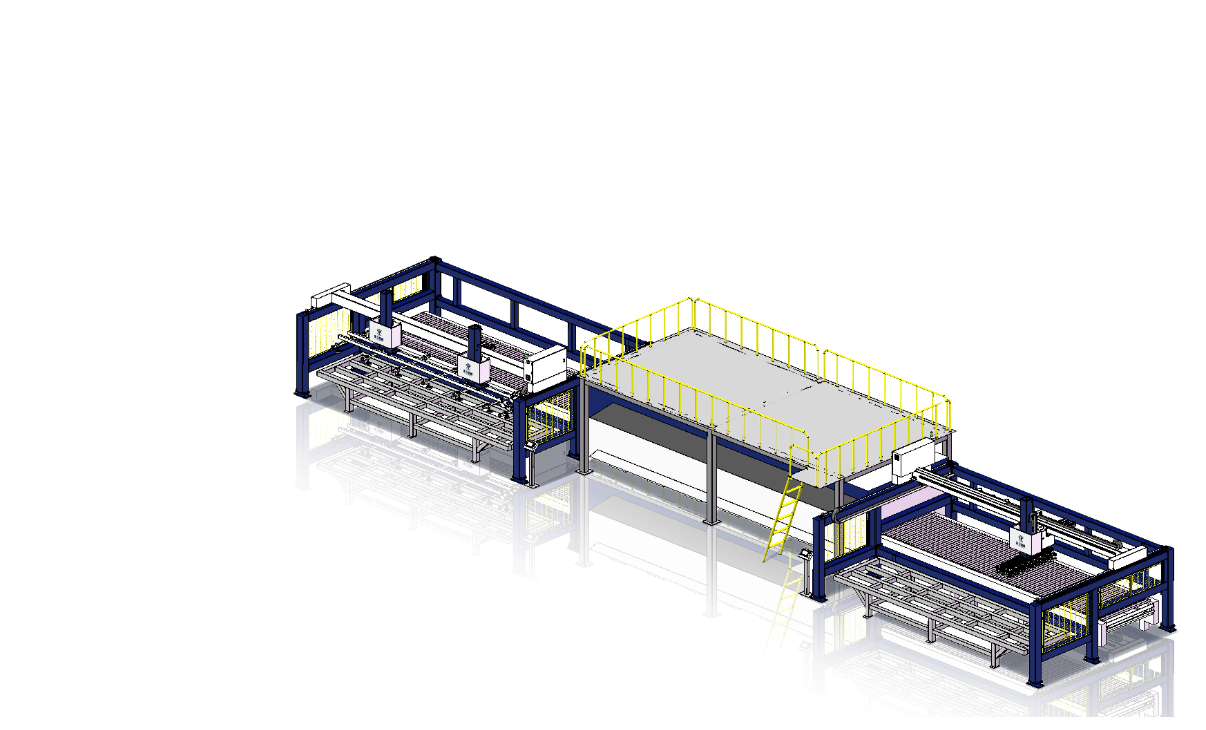

Blanking according to the different processing methods, can be divided into general punching, number punching, cutting plate, laser cutting, etc., due to the different processing methods, the processing technology of blanking is also different. The main methods of sheet metal cutting are punching and laser cutting.

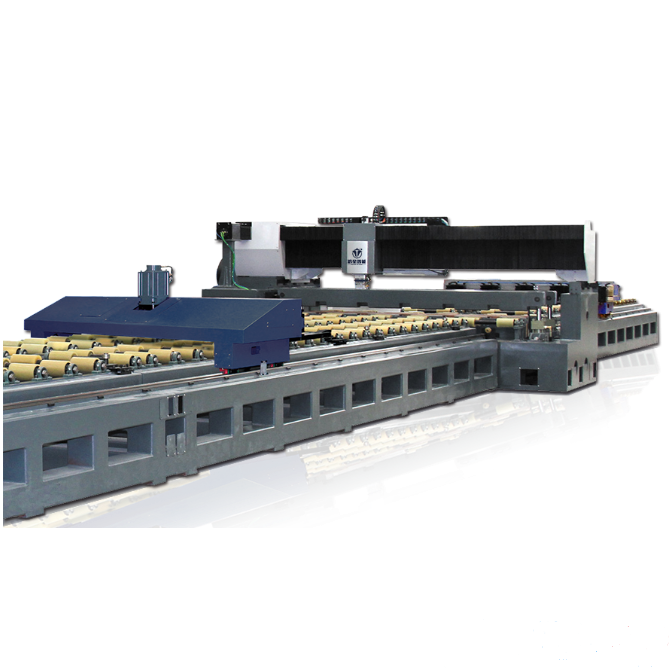

2.1 Digital stamping is processed by CNC turret punching machine. The processing range of plate thickness is cold binding plate and hot binding plate less than or equal to 3.0mm, aluminum plate less than or equal to 4.0mm, stainless steel less than or equal to 2.0mm. The maximum size of the processed sheet is 1250mm*4000mm.

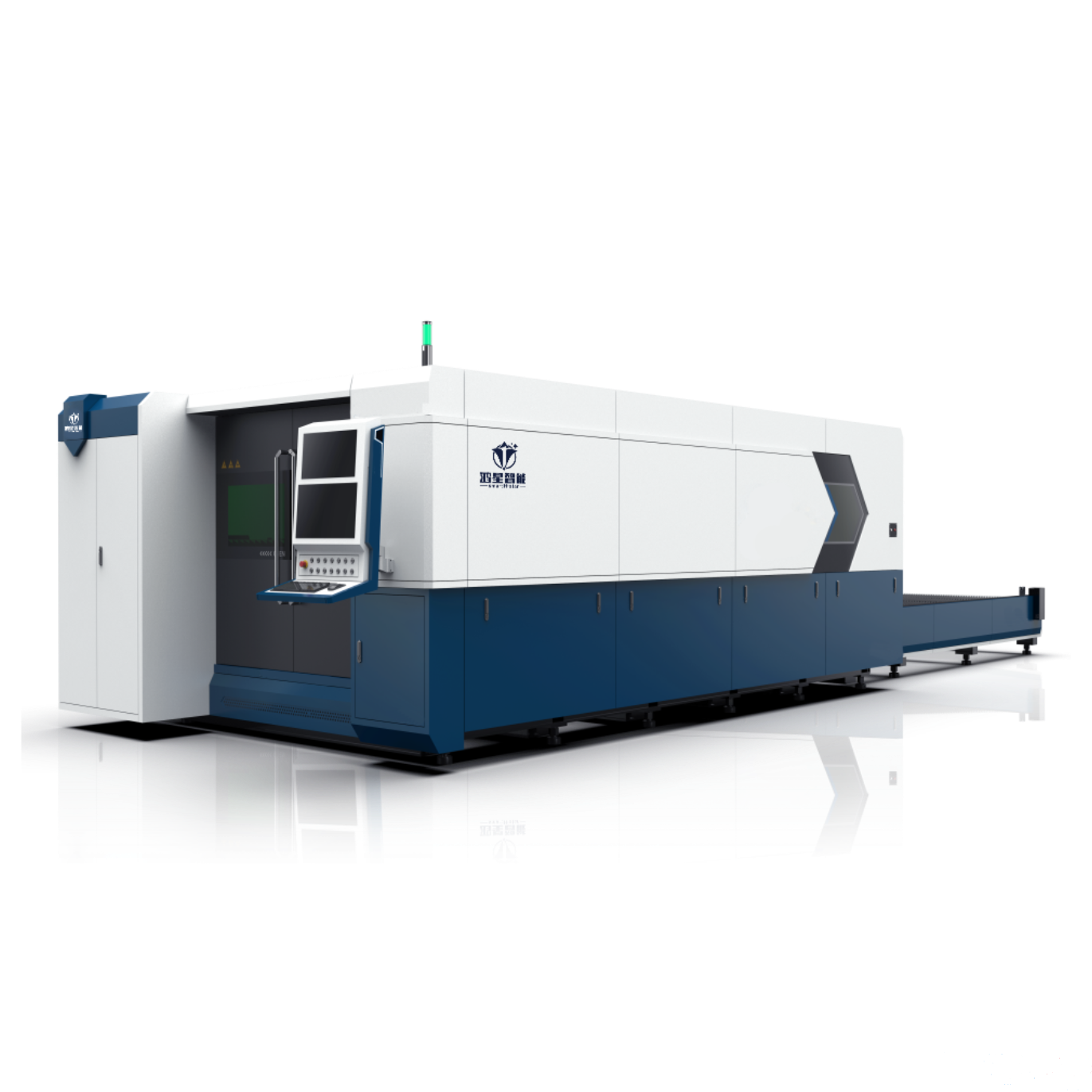

2.2 Laser cutting machine is widely used in modern life and production, he can be divided into three types, YAG solid laser cutting machine, CO2 laser cutting machine, fiber laser cutting machine. Briefly introduce the advantages of three laser cutting machines:

(A) YAG solid laser cutting machine

YAG solid laser cutting machine has the characteristics of low price and good stability, but the energy efficiency is low, the output power of the current product is mostly below 600W, due to the small output energy, mainly used for drilling, spot welding and cutting materials below 8mm. Main advantages: Can cut other laser cutting machine can not cut aluminum plate, copper plate and most non-ferrous metal materials. Main disadvantages: slow cutting speed, can not cut non-metallic materials.

(2) CO2 laser cutting machine

CO2 laser cutting machine, the general power is between 2000-4000W, can stably cut carbon steel within 20mm, stainless steel within 10mm, aluminum alloy below 8mm, as well as wood, acrylic, PP, plexiglass and other non-metallic materials, the main shortcomings: The actual use of operating costs are very high, and the cutting air consumption is very large, it is difficult or even can not cut aluminum plate, copper plate and other highly reflective materials.

(3) Fiber laser cutting machine

Fiber laser cutting machine because it can be transmitted through optical fiber, the general power between 1000W-6000W, the main advantages: less power consumption, easy maintenance, fast, the main disadvantages: accessories consumables and other related maintenance costs are extremely high, it is difficult or even can not cut aluminum plate, copper plate and other highly reflective materials.

The maximum size of laser cutting plate is generally: 1500mm*4000mm, and the minimum aperture of processing is ≥1T.

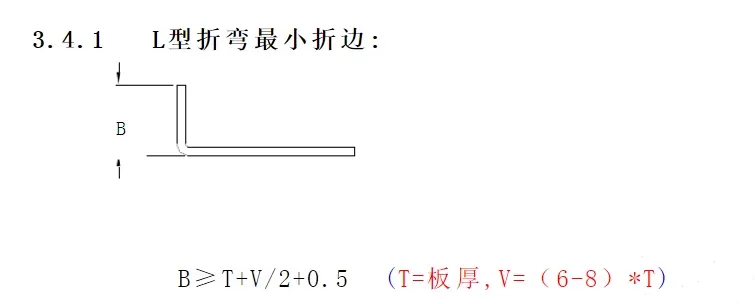

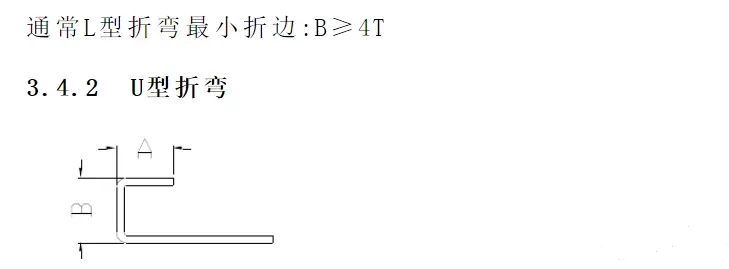

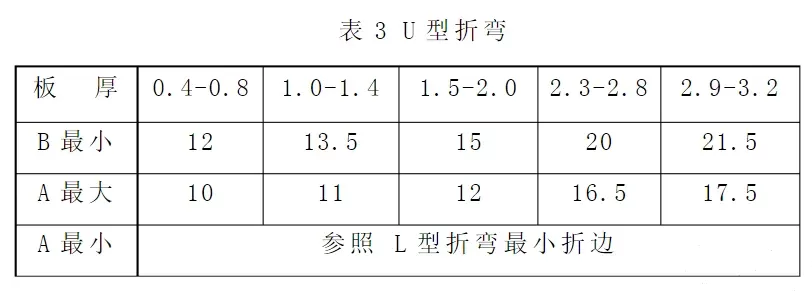

[3] Bend

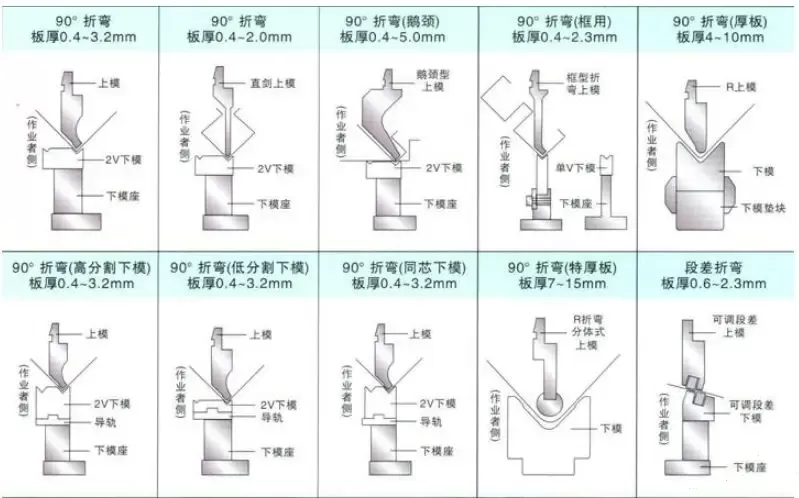

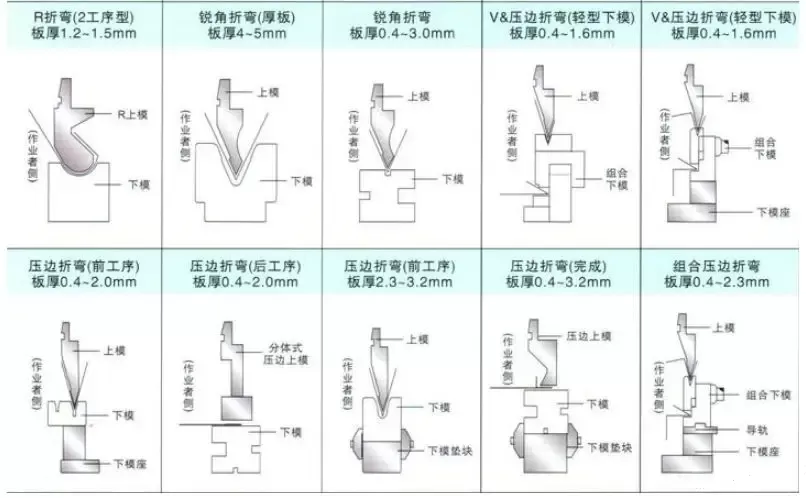

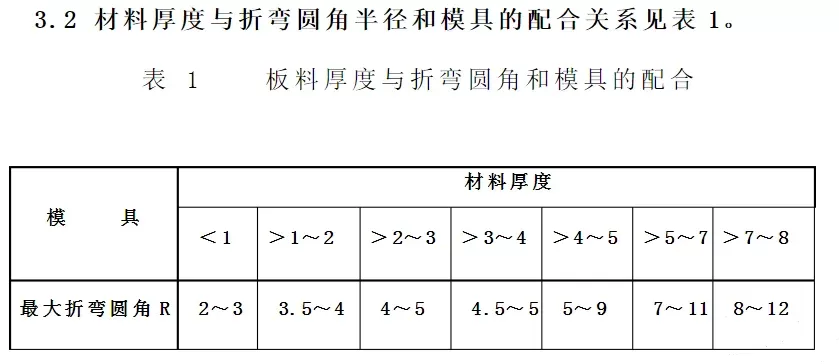

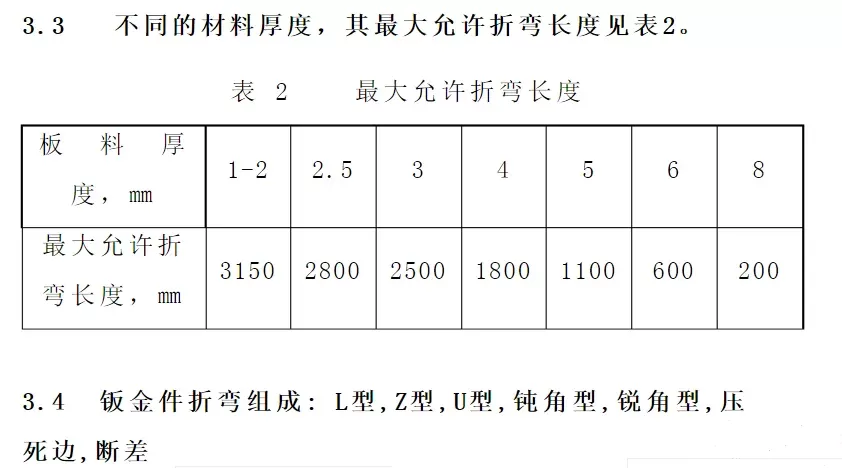

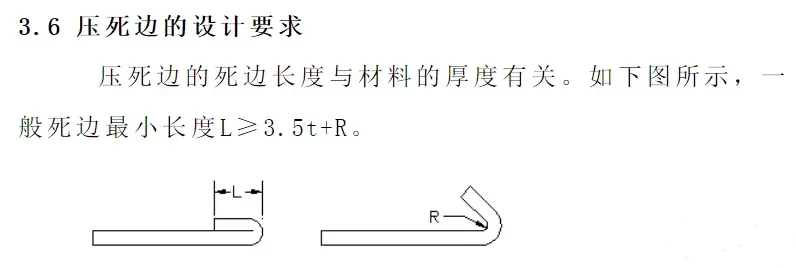

3.1 Commonly used bending mold combination

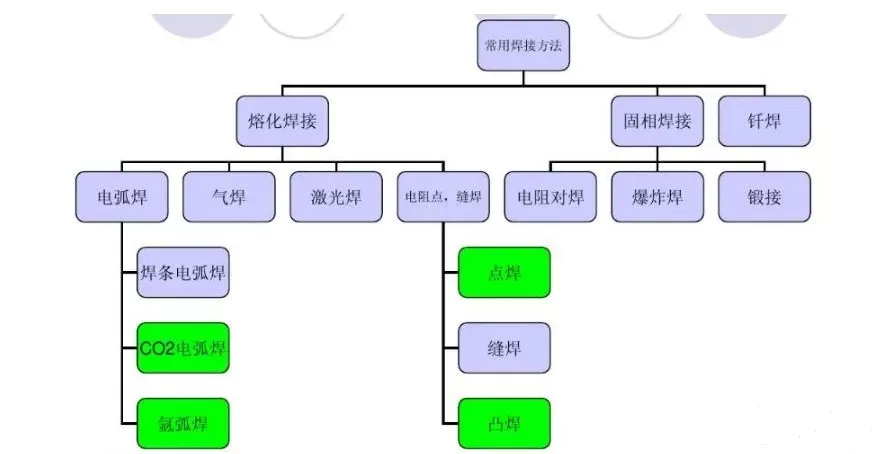

[4] Welding

The welding scheme is as follows:

[5] Grinding

Use grinding wheel, polishing machine and other equipment to polish, remove burrs and welding marks, and make the surface smooth.

[6] Surface treatment

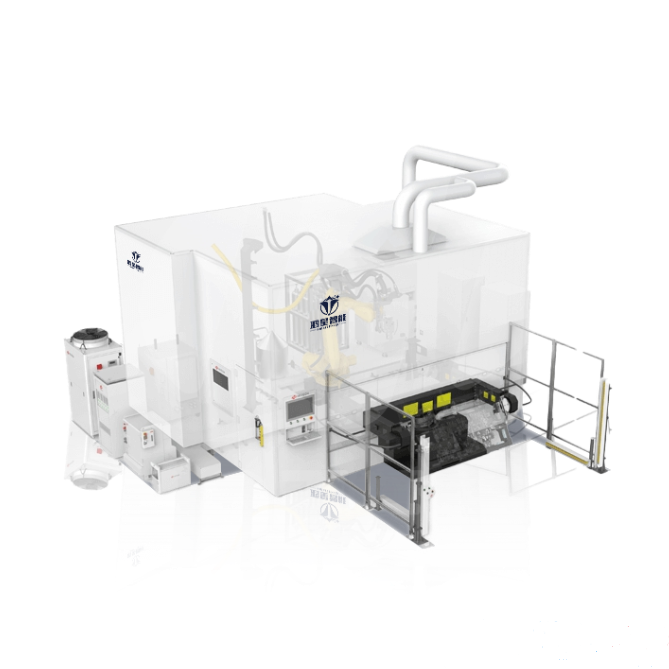

Spraying: Spraying equipment is used to spray the surface to increase the appearance and corrosion resistance.

Spraying: The use of resin materials through electrostatic adsorption on the surface of the metal shell, and finally through high temperature melting in one, to increase the beauty and corrosion resistance.

Electroplating: Electroplating on the surface to increase corrosion resistance and hardness.

Anodizing: Anodizing aluminum to increase surface hardness and corrosion resistance.

[7] Assembly

The finished parts are assembled to form a complete finished product for final inspection and testing.

【 Sheet metal cost estimation 】

Sheet metal cost composition

Materials, processing fees, standard parts and accessories fees, packaging fees, transportation fees, tax rates, management fees, profits, etc

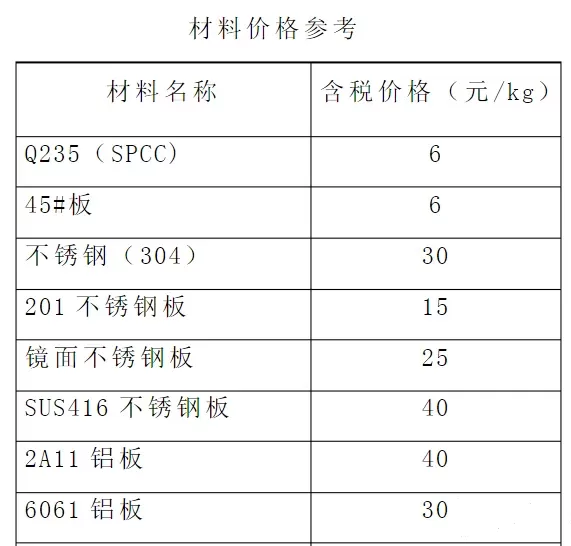

1. Cost of materials

Net material cost + material loss 10%-20% according to drawing requirements

2. Processing fees

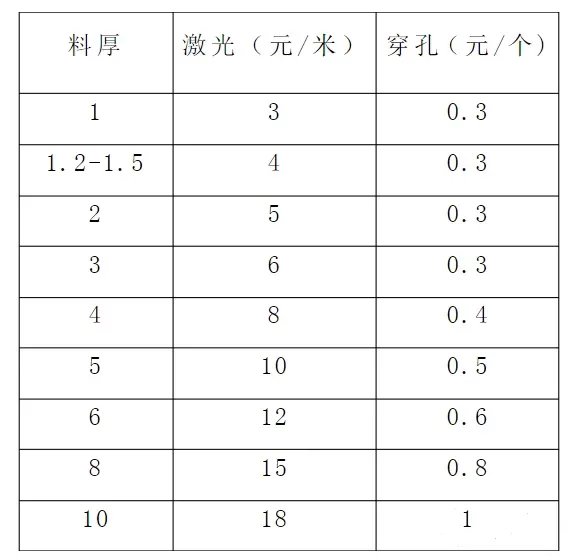

2.1 Laser cutting fee

Calculated according to the actual cutting length of the parts.

2.2 CNC stamping fee

According to the calculation of 200 yuan per hour, the special mold needs to include the mold customization fee of about 1500-3000 yuan, according to the product demand.

2.3 Bending fee

2.3.1 Hourly calculation: 150 yuan/hour

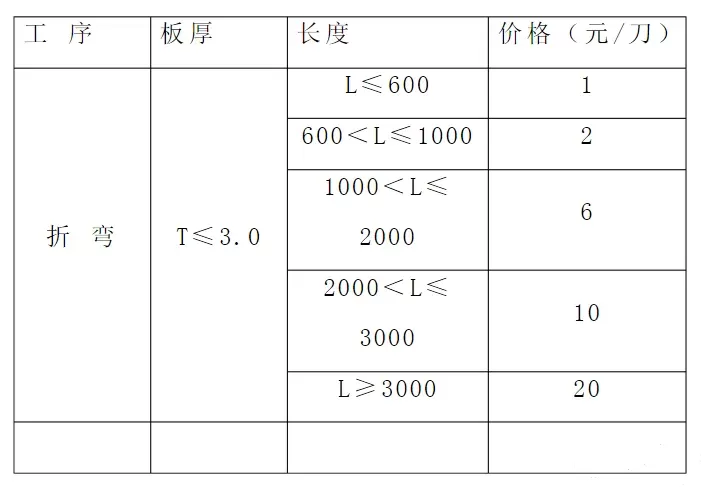

2.3.2 According to the number of bending knives, see the following table:

2.4 Fitter's fee

2.4.1 By hour: RMB 50 / hour

2.4.2 Calculate 0.5 yuan per piece according to the number of sinking hole, pressing riveting, pulling riveting, tapping, reaming and drilling

2.5 Welding Fee

2.5.1 Hourly: 80/ hour

2.5.2 Calculation by length: 25 yuan/meter

2.6 Spray treatment

2.6.1 Indoor powder is calculated at 30 yuan/square meter

2.6.2 Outdoor powder is calculated at 50 yuan/square meter

2.6.3 Small parts spraying no less than 1 yuan/piece (less than 0.01 square meters)

3, standard parts and accessories fees

For products and parts purchased directly by the company from suppliers, pay attention to adding a 5%-15% agency fee when calculating

4, packaging and transportation costs

The packaging and transportation costs incurred during the delivery of the product to the customer are determined according to the actual needs of the customer

5. Administrative expenses

Expenses incurred by administrative departments for organizing and managing production and business activities account for about 10% of the total price

6. Profit

The determination of profit rate, according to the difficulty of processing technology, batch size, etc., can refer to 10%-25%

The following is the detailed cost accounting table:

| item | Unit price (RMB) | quantity | cost(RMB) |

|---|---|---|---|

| Material cost | |||

| board | 10.00 | 5 | 50.00 |

| screw | 0.50 | 20 | 10.00 |

| Labor cost | |||

| Shearing operation | 30.00 | 1 | 30.00 |

| Stamping process | 25.00 | 1 | 25.00 |

| Bending operation | 35.00 | 1 | 35.00 |

| Welding procedure | 40.00 | 1 | 40.00 |

| Grinding process | 20.00 | 1 | 20.00 |

| Surface treatment process | |||

| spray | 20.00 | 1 | 20.00 |

| Other costs | |||

| Transportation charge | 15.00 | 1 | 15.00 |

| Storage charges | 10.00 | 1 | 10.00 |

| Management fee | 10.00 | 1 | 10.00 |

| profit | |||

| Profit margin (10%) | 28.50 | ||

| Total cost | 323.50 |

Note: All prices are for reference only, and are calculated according to the prices quoted by their own supplier system.